Pigment dyeing method for loose cotton fiber

A technology of paint dyeing and dyeing method, which is applied in the field of cotton loose fiber paint dyeing, can solve the problems of high temperature control requirements, long dyeing process time, and large dye waste, so as to achieve enhanced dyeing fastness, increased depth and dyeing fastness , the effect of short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

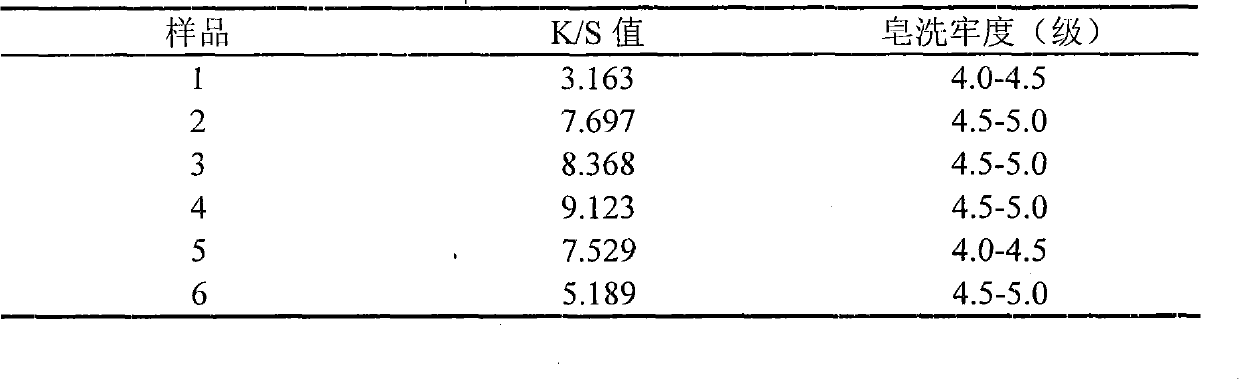

Examples

Embodiment 1

[0057] Cotton loose fibers are arranged to form a cotton fiber web with a thickness of 5mm. The cotton fiber web is transported to the physical pretreatment area by guide rollers, and the cotton fiber web is subjected to ozone treatment. The ozone treatment device adopts a corona device, and the transfer device can use a conveyor belt. The speed is 5 m / min, the working height between the corona treatment device and the cotton fiber web is 5 mm, and the concentration of ozone is 20 mg / L. After the ozone treatment, the cotton fiber web is guided by a guide roller and immersed in 15g / L cationic modifier FK-316, 8g / L fatty alcohol polyoxyethylene ether (JFC), and modified fatty alcohol polyoxyethylene ether can also be used. 0.1% γ-glycidoxypropyltrimethoxysilane, 0.1% ammonium persulfate solution treatment pool, the bath ratio is 1:20, the temperature of the chemical pretreatment solution is 90°C, and then the soaked cotton fiber The web is guided to the roller through the guide ...

Embodiment 2

[0059] Cotton loose fibers are arranged to form a cotton fiber web with a thickness of 5mm. The cotton fiber web is transported to the physical pretreatment area by guide rollers, and the cotton fiber web is subjected to ozone treatment. The ozone treatment device adopts a plasma device, and the transfer device can use a conveyor belt. The speed is 50 m / min, the working height between the plasma treatment device and the cotton fiber web is 1 mm, and the concentration of ozone is 120 mg / L. After physical pretreatment, the cotton fiber web is guided by guide rollers and immersed in 40g / L cationic modifier FK-316, 25g / L fatty alcohol polyoxyethylene ether (JFC), and modified fatty alcohol polyoxyethylene ether can also be used. , 3% γ-glycidoxypropyltrimethoxysilane, 0.5% ammonium persulfate solution in the treatment pool, the bath ratio is 1:20, the temperature of the chemical pretreatment solution is 100°C, and then the soaked cotton The fiber web is guided to the roller throug...

Embodiment 3

[0061] Cotton loose fibers are arranged to form a cotton fiber web with a thickness of 5mm. The cotton fiber web is transported to the physical pretreatment area by guide rollers, and the cotton fiber web is subjected to ozone treatment. The ozone treatment device adopts an ozone generator device, and the conveying device can use a conveyor belt. , the speed is 50 m / min, the working height between the ozone generator treatment device and the cotton fiber web is 1 mm, and the ozone concentration is 120 mg / L. After physical pretreatment, the cotton fiber web is guided by guide rollers and immersed in 40g / L cationic modifier FK-316, 25g / L fatty alcohol polyoxyethylene ether (JFC), and modified fatty alcohol polyoxyethylene ether can also be used. , 3% γ-glycidoxypropyl trimethoxysilane, 0.5% ammonium persulfate solution treatment pool, the bath ratio is 1:20, the temperature of the chemical pretreatment solution is 70 ° C, and then the soaked cotton The fiber web is guided to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com