Catalyst component and catalyst system for olefin polymerization, application of catalyst component and catalyst system, and olefin polymerization method

An olefin polymerization and catalyst technology, which is applied to catalyst components and catalyst systems for olefin polymerization and its application and the field of olefin polymerization, can solve problems such as mutual adhesion of carrier particles, and achieve good particle shape, good shape and high stereo-orientation. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] According to the preparation method of magnesium halide adduct of the present invention, MgX 1 Y, LB 1 , LB 2 And LB 3 It is the same as the previous definition, so I won't repeat it here.

[0077] According to the preparation method of magnesium halide adduct of the present invention, MgX 1 Y, ethanol, LB 1 , LB 2 And LB 3 The dosage can be appropriately selected according to the expected composition of the magnesium halide adduct, as long as MgX 1 Y, ethanol, LB 1 , LB 2 And LB 3 The dosage can make the composition of the final magnesium halide adduct meet the requirements. Generally speaking, relative to 1 mole of MgX 1 Y, the amount of ethanol can be 1-5.5 moles, LB 1 The amount can be 0.005-2.3 moles, LB 2 The amount can be 0.0005 to 0.32 moles, LB 3 The amount of MgX can be 0.0005 to 0.32 moles; preferably, relative to 1 mole of MgX 1 Y, the amount of ethanol is 2-3.7 moles, LB 1 The amount is 0.01-0.85 mole, LB 2 The amount is 0.001-0.12 mole, LB 3 The amount is 0.001...

Embodiment 1

[0174] This example is used to illustrate the catalyst component and catalyst system for olefin polymerization and its application and olefin polymerization method according to the present invention.

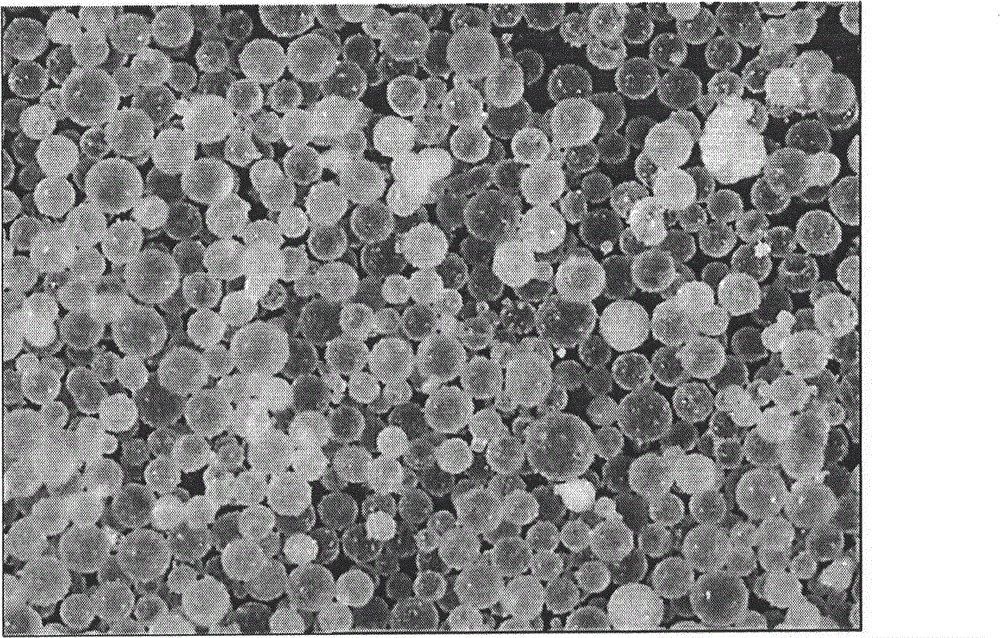

[0175] (1) Preparation of magnesium halide adduct

[0176] In a 500mL reactor, add 150mL white oil, 30g anhydrous magnesium chloride (commercially purchased from Fushun Xinyi Titanium Factory), 50mL of absolute ethanol (commercially purchased from Beijing Chemical Plant, analytically pure), 4mL 2,2-two Methoxypropane (commercially available from Ningbo Warner Chemical Co., Ltd.) and 1 mL of 2-methoxybenzoyl chloride (commercially available from TOKYO KASEI KOGYO CO.LTD) were heated to 120°C under stirring. After a constant temperature reaction for 2 hours, the mixture was pressed into 300 mL of methyl silicone oil (commercially available from Dow Corning, viscosity of 300 cps / 20°C) preheated to 120°C, and stirred at a speed of 1600 rpm for 30 minutes. emulsification. Then, the emul...

Embodiment 2

[0184] This example is used to illustrate the catalyst component and catalyst system for olefin polymerization and its application and olefin polymerization method according to the present invention.

[0185] (1) Preparation of magnesium halide adduct

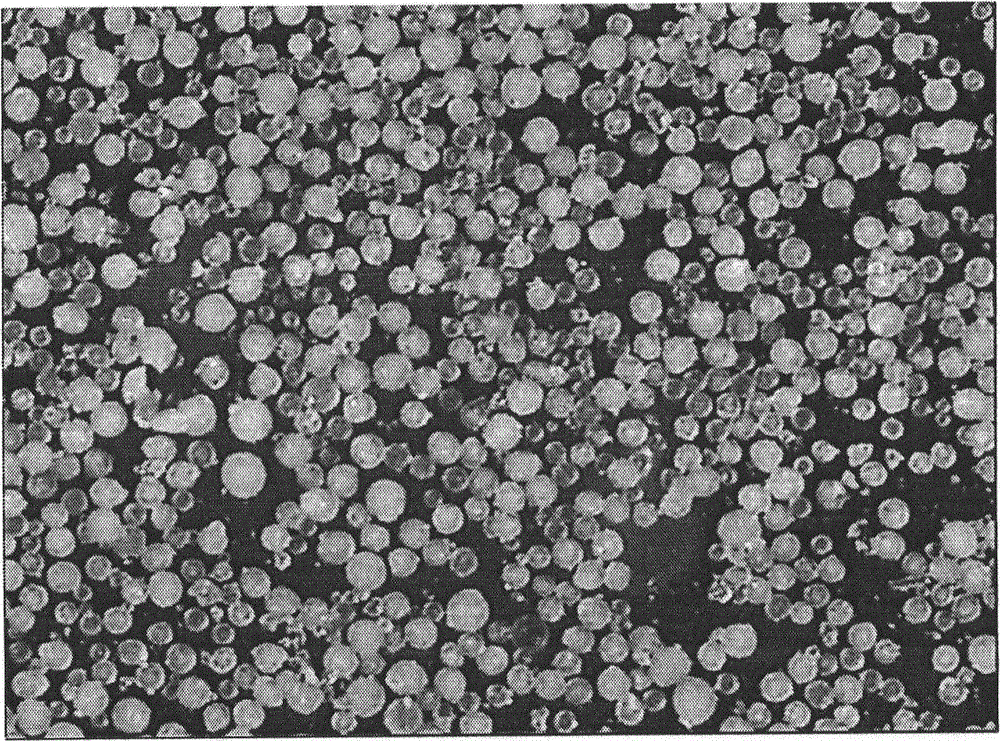

[0186] The spherical magnesium halide adduct was prepared by the same method as in Example 1, except that the amount of 2,2-dimethoxypropane was 9 mL. The composition of the magnesium halide adduct is shown in Table 1, and the particle morphology observed by an optical microscope is as image 3 Shown.

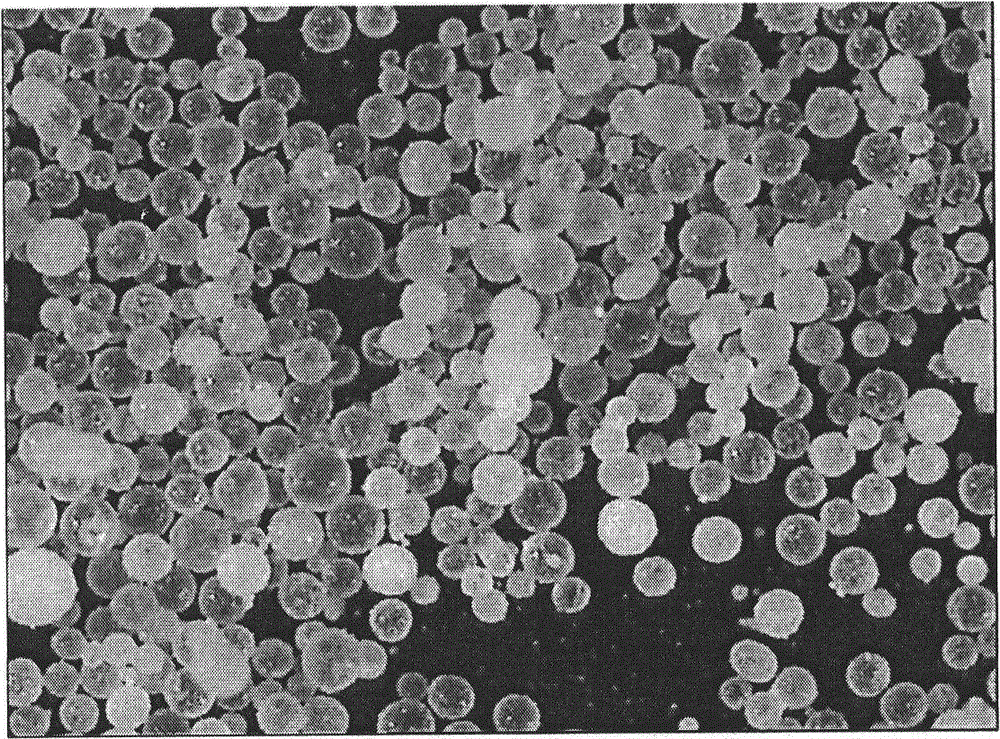

[0187] (2) Preparation of catalyst components

[0188] The spherical catalyst component was prepared by the same method as in Example 1, except that the magnesium halide adduct was the magnesium halide adduct prepared in step (1) of Example 2. The content of titanium in the spherical catalyst component is 2.1wt%, and the particle morphology observed with an optical microscope is as Figure 4 Shown.

[0189] (3) Propylene polymerization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com