Coated polymeric film

A polymer film, polymer technology, applied in the direction of film/sheet adhesive, coating, thin material processing, etc., can solve the problem of blurred printing surface texture, reduce inventory, improve performance, and improve materials The effect of utilization and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] COMPARATIVE EXAMPLES Double-sided coated transparent or opaque polymer films known in the art (such as disclosed by McGee et al. in US Pat. Coating transfer and failure of acceptable bond of coating and / or adhesive to polymeric substrate. Each of these issues should be carefully considered when evaluating acceptable candidates for a particular thin film application. The following inorganic coatings (no ionomer and no crosslinker) were applied to 196 LL B2 (pure polymer film) and 60LH247 (cavitation opaque polymer film) on the six inch wide backside adhesive receiving surface of each.

Water to 15% solids - 124.8g

Wetting Agent Surfactant - Genapol UD 050 (Clariant Corp.) - 0.2g

Ammonia Stabilized Water Insoluble Colloidal Silica - Ludox AS40 - 75.0g

[0082] Using the technique disclosed by McGee in U.S. Patent No. 6,893,722, the following print top coats were prepared and applied at 0.1-0.3 g / m 2 Applied to the printed side of each of the 196 LL B2 (clear) and 6...

Embodiment 2

[0088] Rohm and Haas (R & H), which also manufactures many adhesives including removable adhesive polymers and chemicals, has a laboratory facility in Spring House, Pennsylvania. R & H's laboratories can provide analysis and act as an independent laboratory to evaluate the performance of any of a variety of different substrates in combination with any of R & H's adhesive products, including removable adhesives with R & H properties of coated polymer films used in combination with They can also provide analysis of adhesives and polymeric film substrates used in conjunction with any of a variety of base substrates such as aluminum, stainless steel, thermoplastics, fabrics, paper, and more. The removable adhesive composition is commercially available. For this Example 2, R&H Testing Services was used.

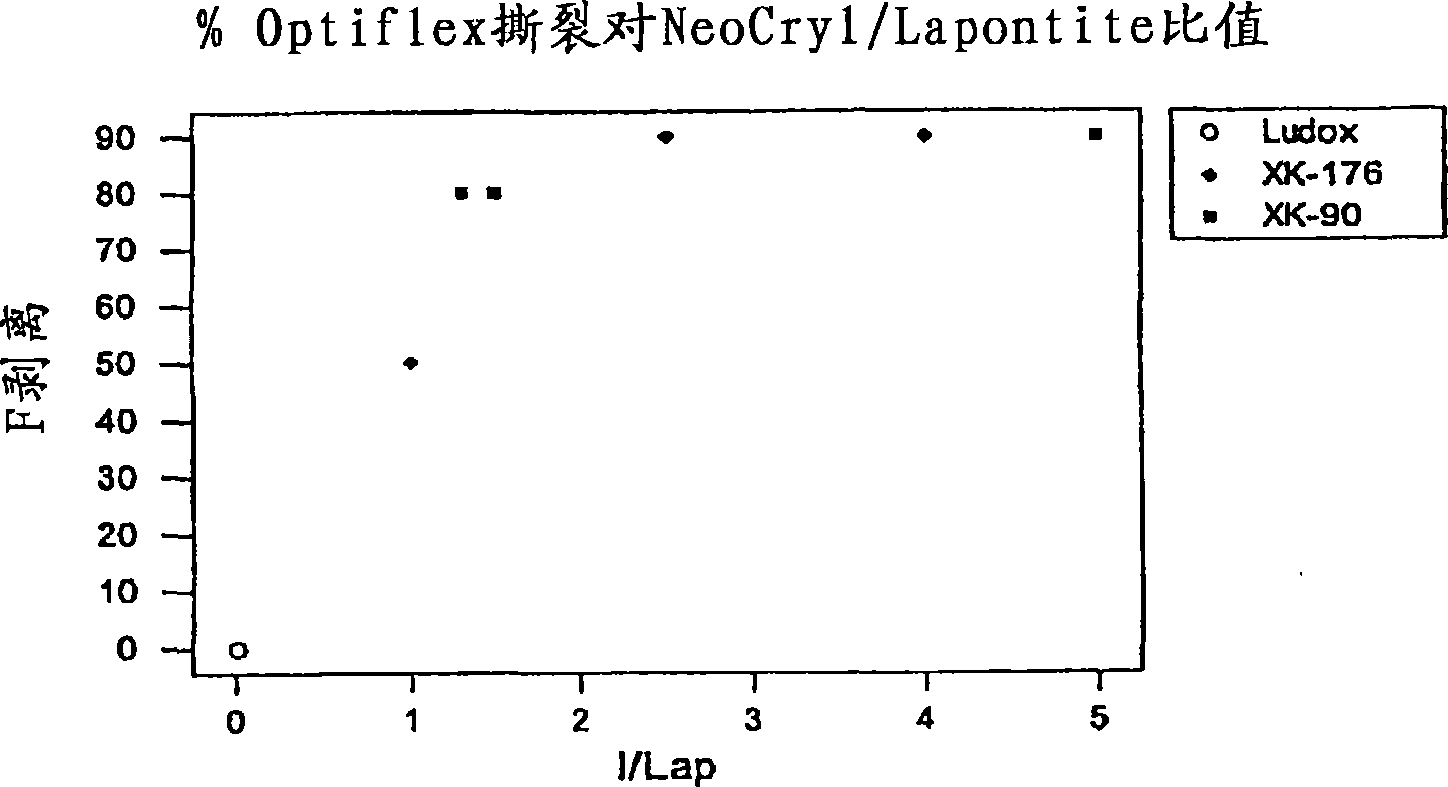

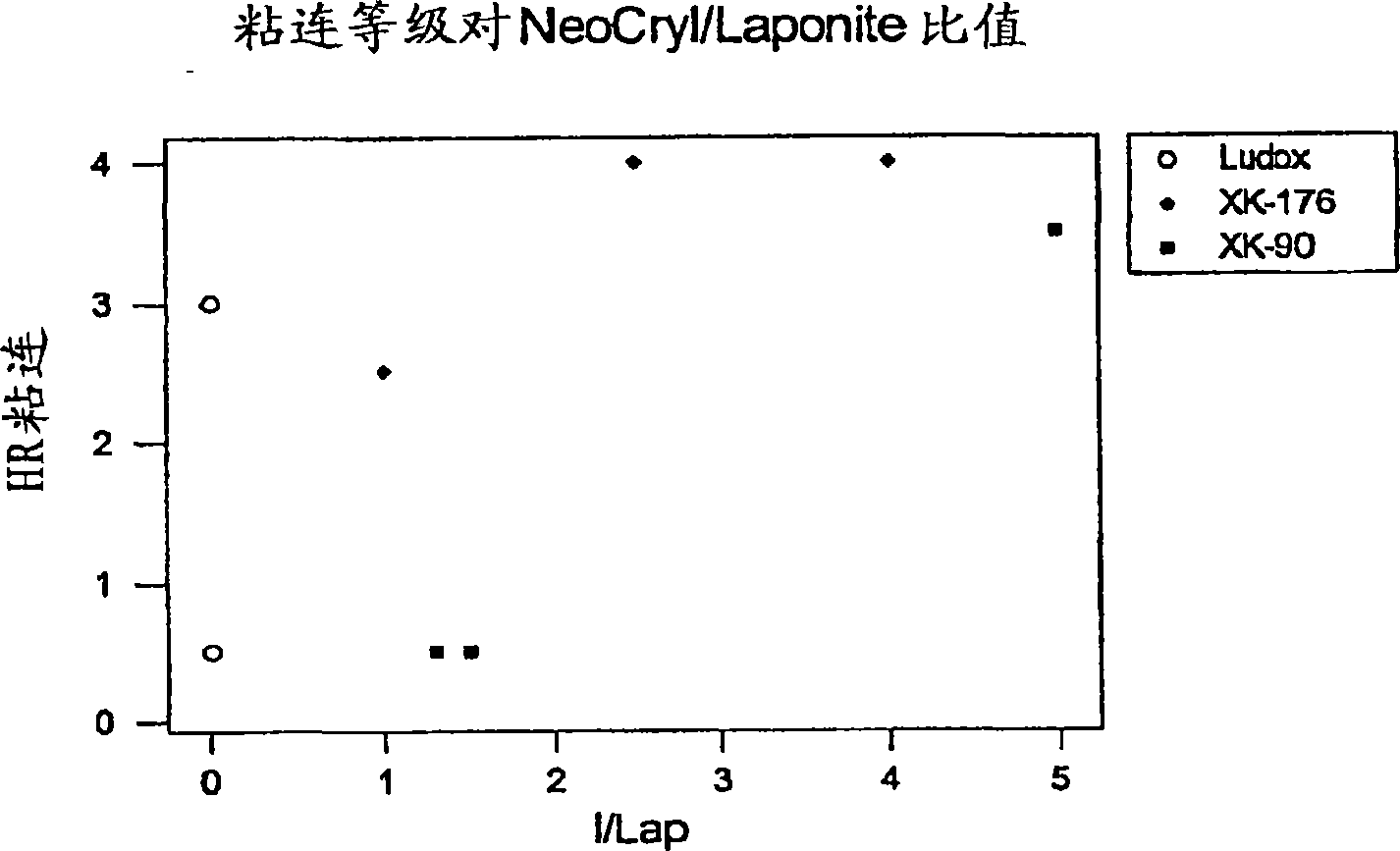

[0089] The following discussion demonstrates one method of how to determine the appropriate amount of crosslinker (using ammonium zirconium carbonate crosslinker and ethylene ac...

Embodiment 3

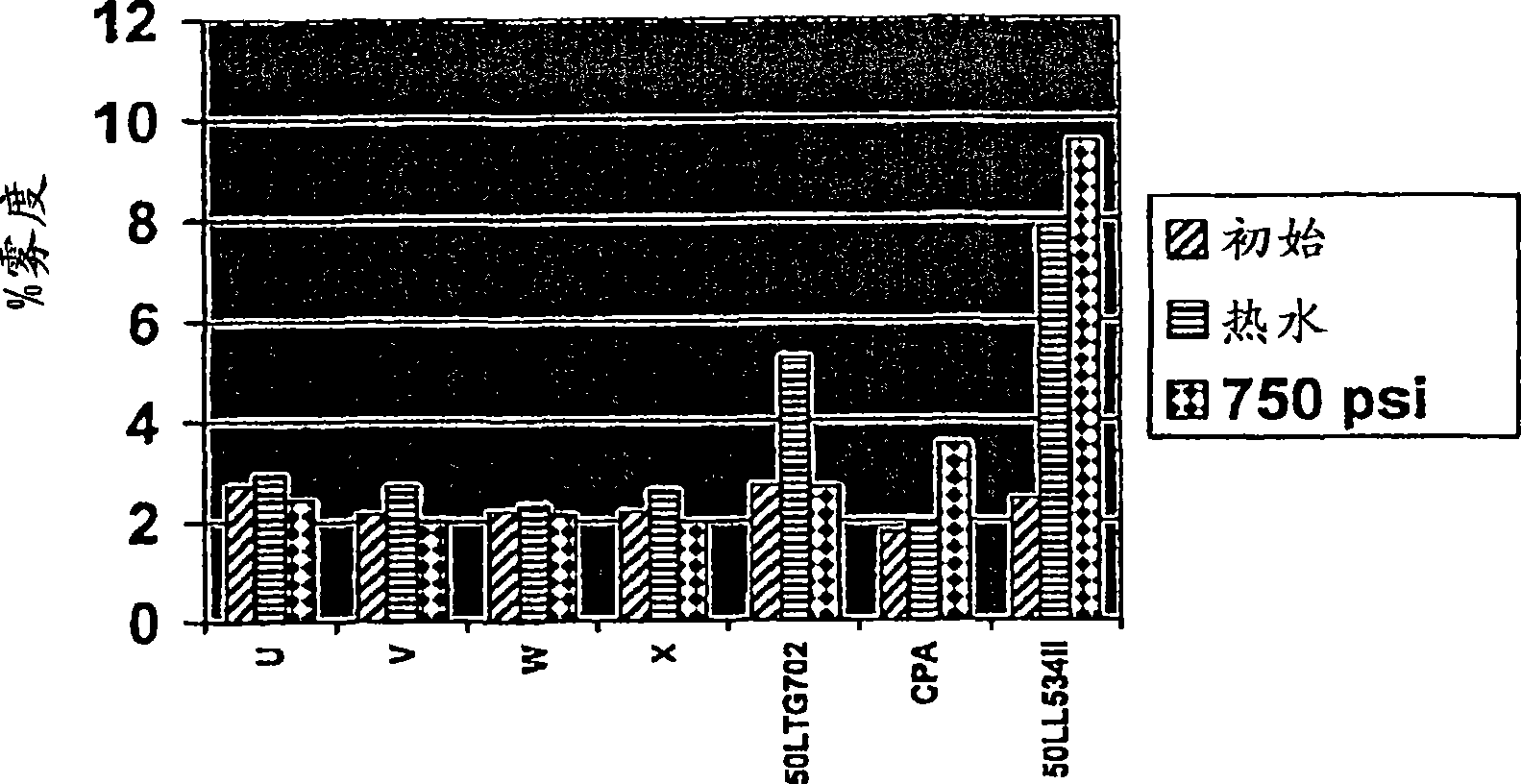

[0099] This example illustrates how the selected samples of Example 2 further performed in the in-coil blocking test. All samples had the same print topcoat as described in Example 1. The results illustrate that some embodiments of the preferred EAA / silica ratio can produce good blocking resistance. The samples were coated and placed in a hot and dry environment (52°C, ~10% RH) for approximately 16 hours on the same day after rewinding. After conditioning, the samples were rewound on a Talboys coater. If the sample tears before it is completely rewound, the number of turns on the three inch film of the receiver core is measured at the point of tear. Higher numbers indicate improved, but still unacceptable results for many applications. Fully rewound samples were designated as "Acceptable" in the "Rewind" column.

table 3

In-coil Blocking Test, Blocking Results and EAA / Silica Ratio

sample Rewind (Number of rolls when tearing) EAA / Silica A tear(0) N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com