Hot-melt splicing adhesive tape

A technology of hot-melt adhesive layer and tape, applied in the direction of adhesives, heat-activated films/sheets, adhesive types, etc., can solve the problems of easy aging of double bonds, aging of export products, and restrictions on the export of electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First, polyacrylate pressure-sensitive adhesives were synthesized according to the above method and ratio.

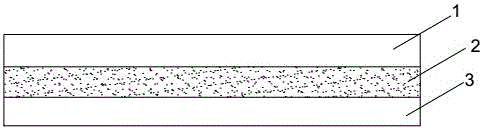

[0024] like figure 1 As shown, a hot-melt braided tape includes a textured paper substrate layer 1, a release layer 2, and a hot-melt adhesive layer 3.

[0025] Wherein said hot melt adhesive layer is synthesized according to the following method:

[0026] Take 40 parts of acrylate glue, 0.002 parts of diisocyanate, 5 parts of modified phenolic resin, 1.4 parts of liquid rosin resin, 1.8 parts of naphthenic oil, 0.04 part of silane coupling agent, and an appropriate amount of ethyl acetate.

[0027] Then mix and stir evenly, coat on textured paper with a coating thickness of 50um, dry at 130°C for 3min, and cut into 12mm width to obtain the finished product.

[0028] Then perform a performance test, the specific data is as follows:

[0029] Initial viscosity: low; Pull-out force: 60-90N / in; 85℃×85RH×500h: Capacitor feet bounce off.

Embodiment 2

[0031] First, polyacrylate pressure-sensitive adhesives were synthesized according to the above method and ratio.

[0032] like figure 1 As shown, a hot-melt braided tape includes a textured paper substrate layer 1, a release layer 2, and a hot-melt adhesive layer 3.

[0033] Wherein said hot melt adhesive layer is synthesized according to the following method:

[0034] Take 40 parts of acrylate glue, 0.002 parts of diisocyanate, 5 parts of modified phenolic resin, 2.2 parts of naphthenic oil, 0.12 parts of silane coupling agent, and an appropriate amount of ethyl acetate.

[0035] Then mix and stir evenly, coat on textured paper with a coating thickness of 50um, dry at 130°C for 3min, and cut into 12mm width to obtain the finished product.

[0036] Then perform a performance test, the specific data is as follows:

[0037] Initial viscosity: very low; pull-out force: 14-20N / in; after placement, the viscosity decreases and the taping property decreases.

Embodiment 3

[0039] First, polyacrylate pressure-sensitive adhesives were synthesized according to the above method and ratio.

[0040] like figure 1 As shown, a hot-melt braided tape includes a textured paper substrate layer 1, a release layer 2, and a hot-melt adhesive layer 3.

[0041] Wherein said hot melt adhesive layer is synthesized according to the following method:

[0042] Take 40 parts of acrylate glue, 0.003 part of diisocyanate, 4 parts of modified phenolic resin, 2 parts of naphthenic oil, 0.08 part of silane coupling agent, and an appropriate amount of ethyl acetate.

[0043] Then mix and stir evenly, coat on textured paper with a coating thickness of 50um, dry at 130°C for 3min, and cut into 12mm width to obtain the finished product.

[0044] Then perform a performance test, the specific data is as follows:

[0045] Initial tack: high; pulling force: 64-80 N / in.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com