Pulsed flashing butt welding method for 780Mpa-grade hot-rolled dual-phase wheel steel

A technology of flash butt welding and wheel steel, which is applied in welding equipment, resistance welding equipment, manufacturing tools, etc., can solve the problems of increased difficulty, deterioration of formability, and increased sensitivity of fatigue notches, etc., to achieve low spatter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

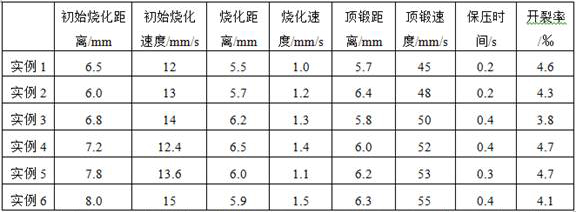

[0031] Examples 1-6 were welded using the above-mentioned implementation method. See Table 1 for the initial burning distance, initial burning speed, burning distance, and burning speed in the pulse flash stage, and Table 1 for the upsetting distance, upsetting speed, and pressure holding time in the upsetting stage. See Table 1 for the welding cracking rate of Examples 1-6.

[0032] Table 1

[0033]

[0034] The welded joints of the wheel rims of Examples 1-6 are good, without surface defects and invisible cracks, the performance of the weld area is good, there are no quality defects of thinning and softening, and the cracking rate is within 5‰.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com