Vanadium ion liquid flow accumulator battery

A liquid flow battery and vanadium ion technology, applied in secondary batteries, regenerative fuel cells, secondary battery manufacturing, etc., can solve the problems of volume limitation, battery failure, falling off, etc., and achieve the effect of high rate discharge cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

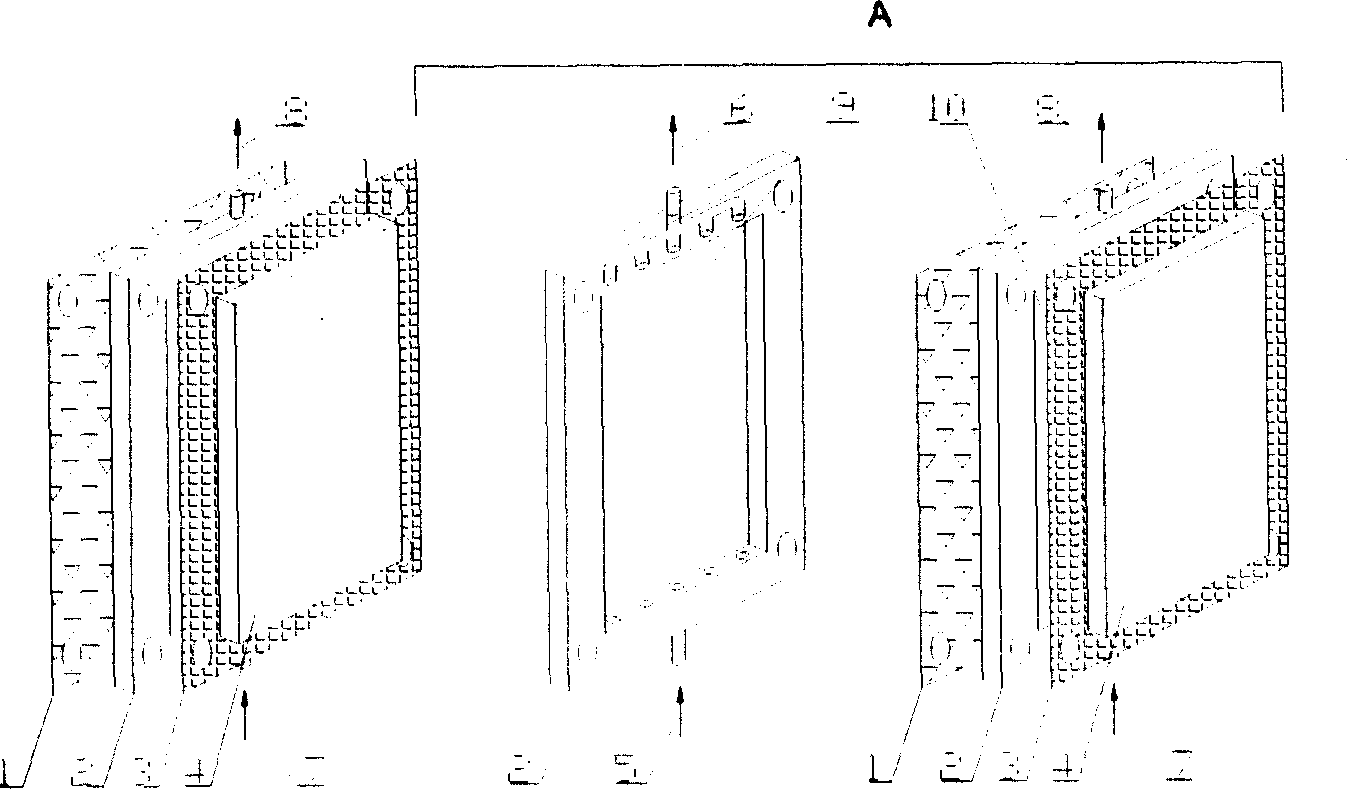

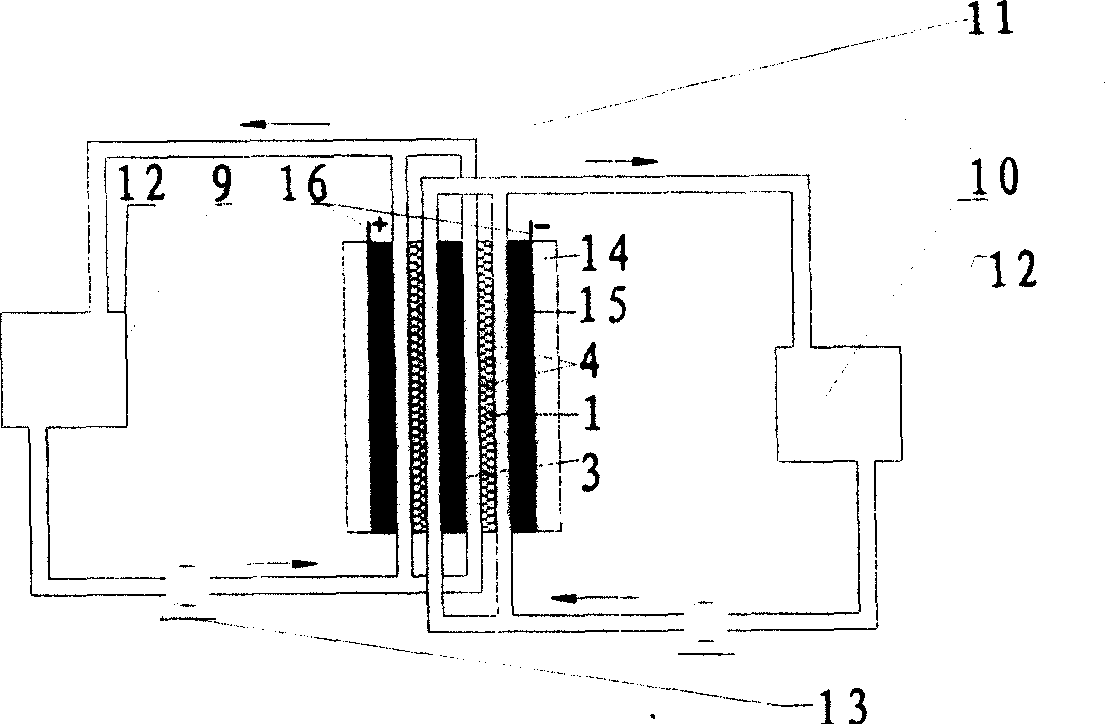

[0026] specific implementation

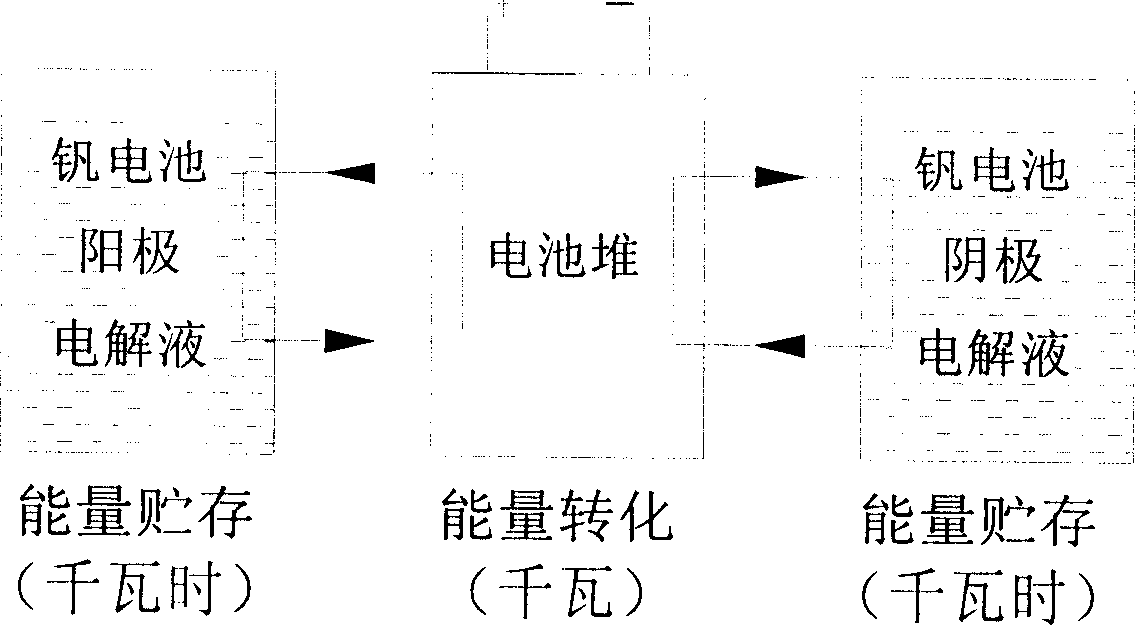

[0027] Two electrolyte pools 12 and several layers of battery cells are formed. The electrolyte pools 12 hold anode and catholyte solutions 9 and 10 respectively, and the anolyte solution 9 contains 9mol / L of H 2 SO 4 and 1~2mol / L (VO 2 ) 2 SO 4 Solution (optimally 2mol / L), the balance is water; catholyte 10 contains 9mol / L of H 2 SO 4 And 1~2mol / L VSO 4 Solution (optimally 2mol / L), the balance is water. The several layers of battery cells are stacked together, and each battery cell is formed by stacking bipolar electrodes 3, felt membranes 4, flow frames 2, separators 1, flow frames 2, felt membranes 4, and bipolar electrodes 3 in sequence , the diaphragm 1 separates the single cell into positive and negative two half-units; each electrolyte pool 12 is equipped with a pump 13, connected to each half-unit with a sealed pipeline 11; the flow frame 2 is a sealed pipeline 11 that flows through each half-unit The chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com