System and method for realizing stable combustion and carbon emission reduction of thermal power plant by utilizing blending combustion of biofuel ethanol

A bio-fuel, fuel ethanol technology, applied in the direction of using a variety of fuel combustion, combustion methods, using block fuel and liquid fuel combustion, etc., can solve the problems of high economic cost, boiler flameout, and no help in carbon emission reduction, etc. achieve the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

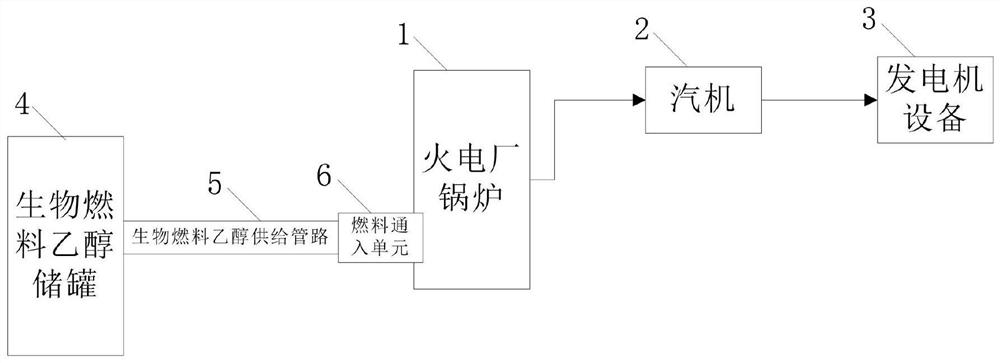

[0051] A thermal power plant blending biofuel ethanol combustion stable and carbon emission reduction system, such as figure 1 As shown, it includes a thermal power plant boiler 1, a steam turbine 2 and a generator equipment 3, the thermal power plant boiler 1 is connected to the steam turbine 2, the steam turbine 2 is connected to the generator equipment 3, and the thermal power plant blends biofuel ethanol for stable combustion And the carbon emission reduction system also includes a biofuel ethanol storage tank 4, a biofuel ethanol supply pipeline 5 and a fuel inlet unit 6, the fuel inlet unit 6 is arranged on the thermal power plant boiler 1, and the biofuel ethanol storage tank 4 passes through the biofuel The ethanol supply pipeline 5 is connected to the fuel inlet unit 6, and the biofuel ethanol storage tank 4 stores the biofuel ethanol converted from any one of grain, biomass, lignocellulose, and sugarcane sugar plants, It is supplied to the boiler 1 of the thermal pow...

Embodiment 2

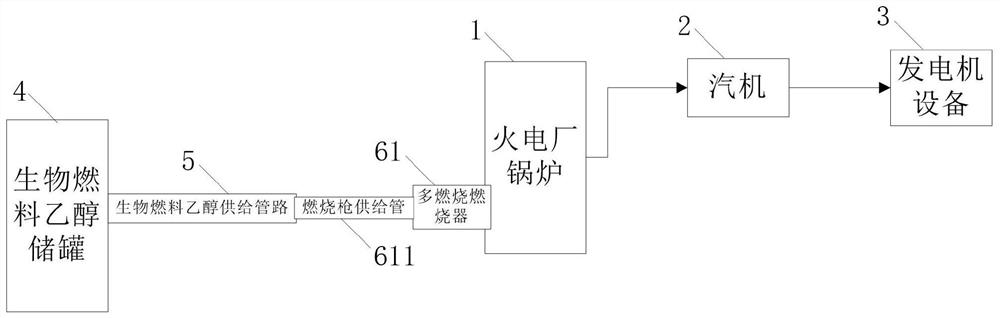

[0053] like figure 2 As shown, on the basis of Embodiment 1, the fuel inlet unit 6 includes a multi-fuel burner 61, and a combustion gun supply pipe 611 is arranged on the multi-fuel burner 61, and the biofuel ethanol supply pipeline 5 will The biofuel ethanol storage tank 4 is connected to the combustion gun supply pipe 611 of the multi-fuel burner 61 arranged on the thermal power plant boiler 1 .

Embodiment 3

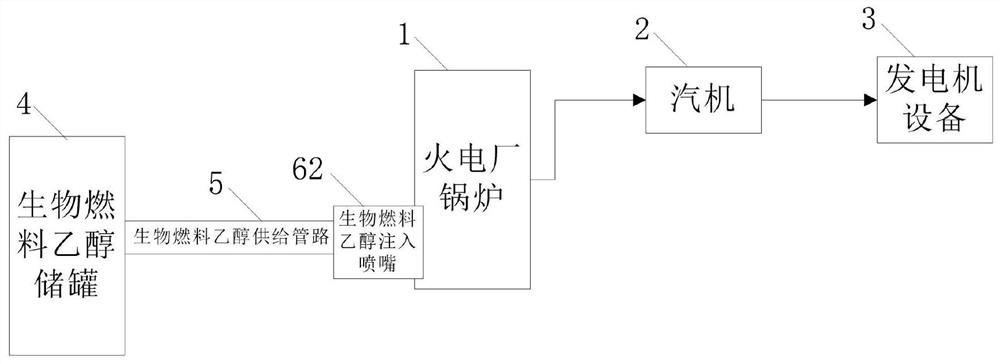

[0055] like image 3 As shown, on the basis of Embodiment 1, the fuel inlet unit 6 includes a biofuel ethanol injection nozzle 62, and the biofuel ethanol supply pipeline 5 connects the biofuel ethanol storage tank 4 with the biofuel ethanol provided on the boiler 1 of the thermal power plant. Fuel ethanol injection nozzle connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com