Multi-energy hybrid power hydraulic pumping unit

A technology of hybrid power and pumping unit, applied in mechanical structure design, hydraulic pumping unit field, to achieve remarkable effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

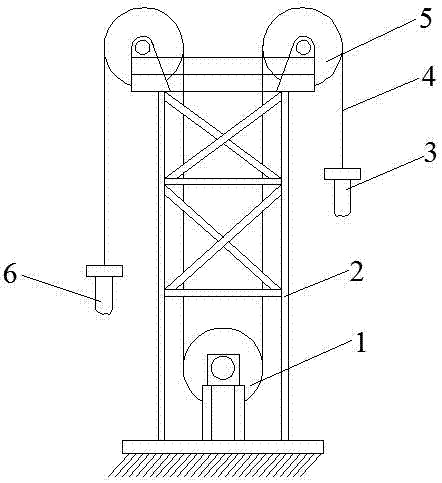

[0011] Such as figure 1 As shown, the mechanical structural unit of the new energy-saving hydraulic pumping unit is mainly composed of a driving drum, a frame, a sucker rod 1 and a sucker rod 2, a steel wire rope, two sky wheels and the like. The two sucker rods are connected by wire ropes after passing through the crown wheel, and are balanced and symmetrically arranged on both sides of the driving drum, and the wire ropes on both sides of the driving drum are wound in opposite directions, so that when the sucker rod on the side of the driving drum rises to pump oil At the same time, the sucker rods on the other side are lowered synchronously, forming double wells to operate alternately to pump oil, and achieve continuous oil pumping. In addition, for oil production areas where it is not suitable to install two oil wells at a relatively short distance, the sucker rod on the side of the drive drum can be changed to a balance counterweight. Well pumping oil.

Embodiment 2

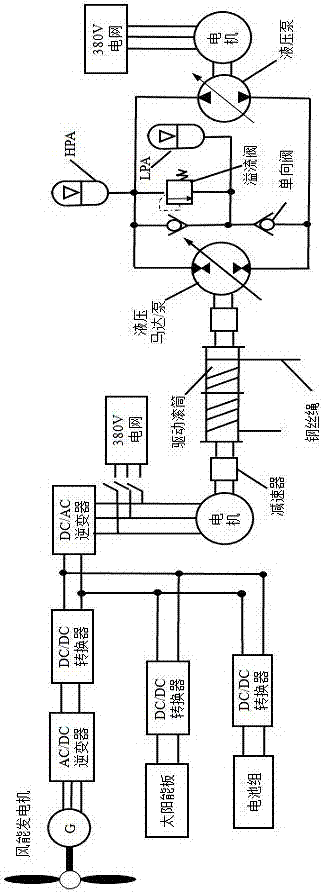

[0013] Such as figure 2 As shown, the drive system of the new energy-saving hydraulic pumping unit is composed of a hydraulic hydrostatic transmission system and a small wind-solar hybrid power generation system. Among them, the hydraulic hydrostatic transmission system is mainly composed of motor, variable hydraulic pump, check valve, overflow valve, high pressure accumulator (HPA), low pressure accumulator (LPA), secondary component hydraulic motor / pump and hydraulic pipeline . The small-scale wind-solar hybrid power generation system is mainly composed of wind power generators, AC / DC inverters, DC / DC converters, solar panel arrays, battery packs, etc. Its main working principle is as follows:

[0014] When the sucker rod is in the acceleration stage, the energy is provided by the hydraulic system at this time, and the secondary element works according to the motor condition and adjusts the displacement in real time according to the load to meet the load demand; The powe...

Embodiment 3

[0016] Such as figure 2 As shown, the wind power generation system can also work in the grid-connected mode. At this time, the switch is closed, and the electric energy generated by the wind power generation system is used to drive the motor and drive the sucker rod to run at a constant speed. If the power generated by the wind power generation system is excessive , will be directly incorporated into the grid, and when the generated electric energy is insufficient, it can directly absorb energy from the grid to drive the motor to run normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com