A kind of 390mpa class polar hull structural steel with low temperature toughness and preparation method thereof

A low-temperature toughness and structural steel technology, applied in the field of micro-alloy steel, can solve the problems of not being able to meet the use conditions of the polar environment temperature and high production costs, and achieve the effects of cost reduction, low-temperature toughness improvement, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing a 390MPa grade polar hull structural steel with low temperature toughness, comprising the following steps:

[0036] Step 1. After the molten iron is stirred and desulfurized by KR, the S content is guaranteed to be ≤0.005%, and the desulfurization time is ≤25min;

[0037] Step 2, adding high-quality scrap steel, using a converter for smelting, using Al in the ladle for deep deoxidation, and adding ferroniobium after deoxidation;

[0038] Step 3. In the LF refining stage, white slag is produced first, desulfurization and target composition adjustment are performed, and then titanium wire and calcium wire are fed in sequence. After the alloying is completed, the ladle is hoisted to the continuous casting platform;

[0039] Step 4. The continuous casting process adopts the whole process of protective pouring to ensure that the superheat of the molten steel is 10-30°C, the casting speed is controlled at 0.6-1.5m / min, and the s...

Embodiment 2

[0053] This embodiment provides a 390MPa grade polar hull structural steel with low temperature toughness, the chemical composition of the steel plate is C 0.08-0.12%, Si 0.10-0.20%, Mn1.0-2.0%, S≤0.005 %, P≤0.005%, Als 0.02-0.03%, Ti 0.01-0.02%, N≤0.0040%, Nb 0.015-0.030%, and the rest is Fe.

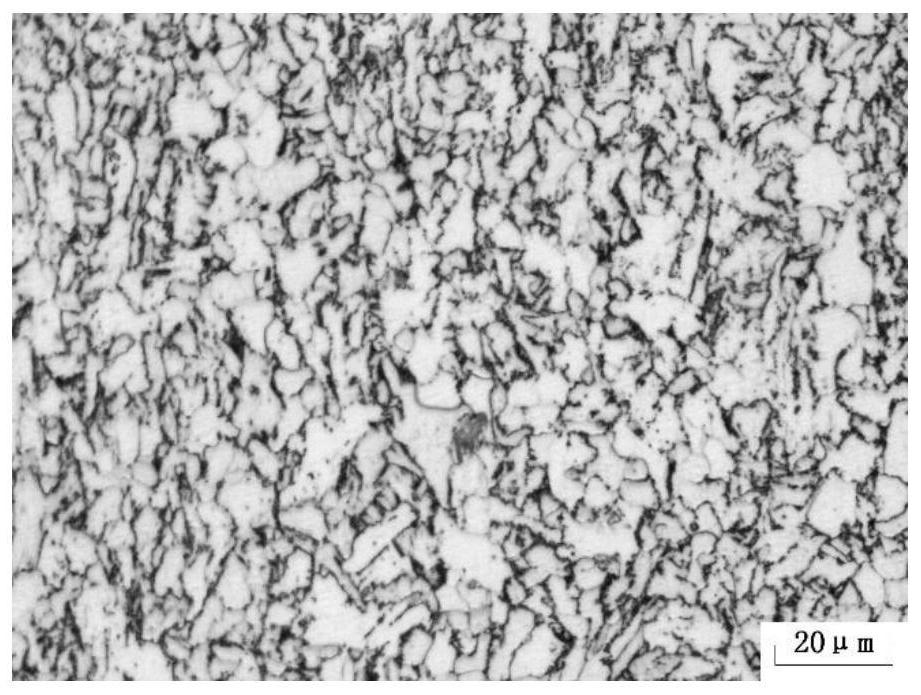

[0054] Compared with the existing technology, the 390MPa grade polar hull structural steel with low temperature toughness provided by the application does not add precious metal elements such as Ni, Cr, Mo, V and other elements to the components, which greatly saves production costs; through the rolling process The relatively fine ferrite structure is obtained, which greatly improves the toughness of the polar hull structural steel.

[0055] Exemplarily, the chemical composition of steel is C 0.08%, Si 0.1%, Mn 1.5%, S 0.004%, P0.005%, Als 0.02%, Ti: 0.015%, N 0.0030%, Nb: 0.015%, and the rest are Fe.

[0056] Exemplarily, the chemical composition of the steel is C 0.10%, Si 0.2%, Mn...

Embodiment 3

[0067] This embodiment provides a 390MPa class polar hull structural steel with low temperature toughness. The chemical composition is C0.08%, Si 0.1%, Mn 1.5%, S 0.004%, P 0.005%, Als 0.02%, Ti: 0.015% , N0.0030%, Nb: 0.015%, and the rest is Fe.

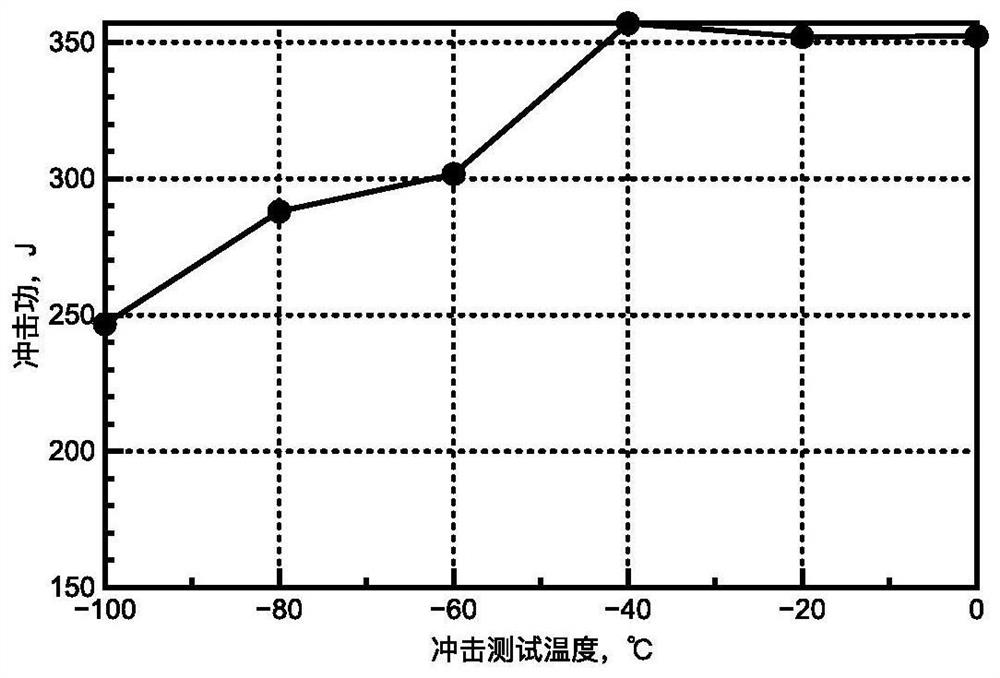

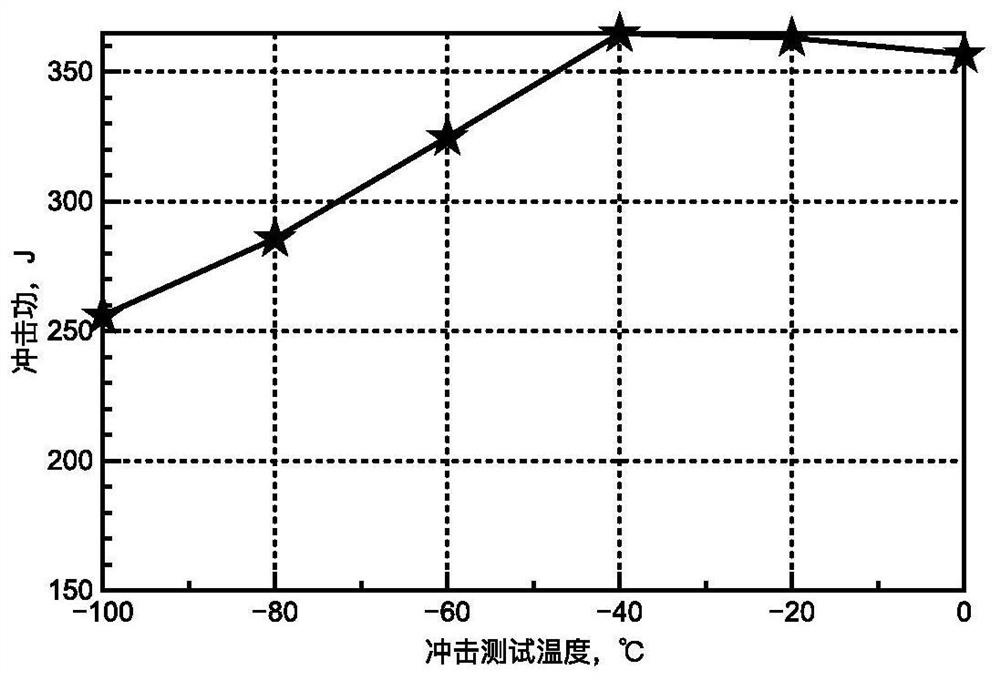

[0068] Converter smelting is adopted, the thickness of the rolled steel plate is 40mm, the thickness of the continuous casting slab used is 360mm, the continuous casting slab is heated to 1130°C, the first stage undergoes three passes of longitudinal rolling, the final rolling temperature is 1000°C, and the cumulative deformation is 55 %, the thickness of the intermediate billet is 162mm; the temperature of the second-stage rolling is 820°C, after four passes of rolling, the final rolling temperature is 770°C, and the final rolling deformation is not less than 20%; immediately after rolling, water cooling is adopted, and the cooling rate is 10.5°C / s. The mechanical properties are shown in Table 1, and the temperature impact energy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com