Production method of ultrafine microstructure hot rolling carbon steel strip with yield strength of 355MPa

A technology of yield strength and manufacturing method, which is applied in the field of steel manufacturing, can solve problems such as damage to toughness, and achieve the effects of improved toughness, low hardenability tendency, and good forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment:

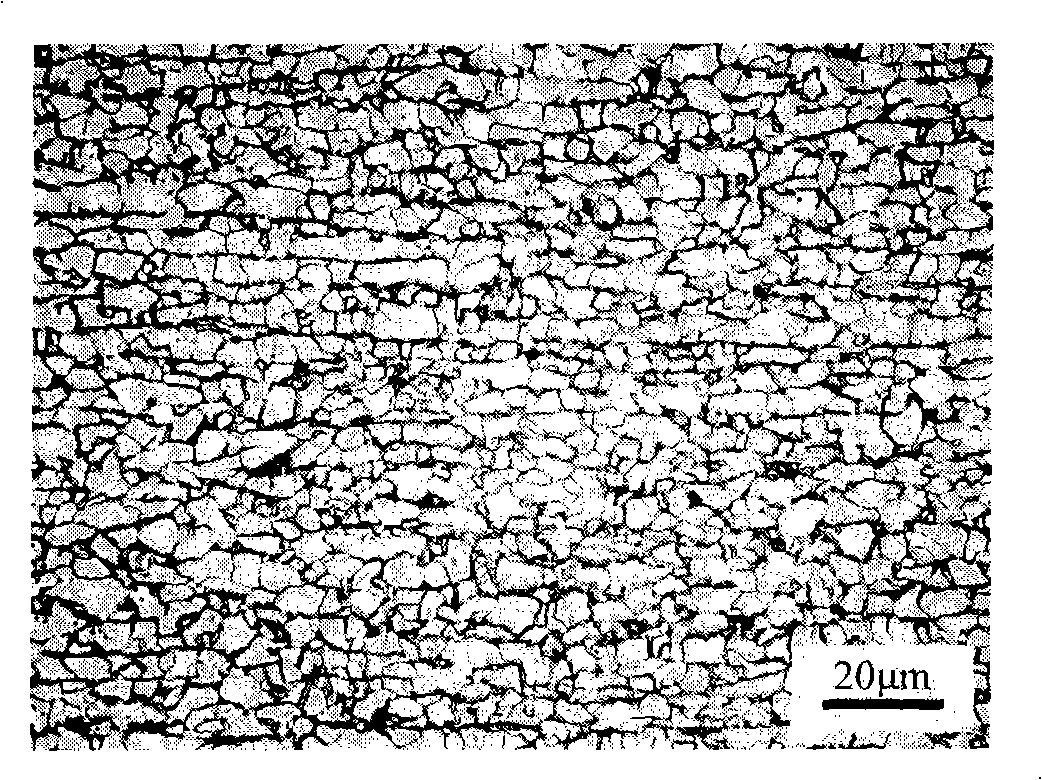

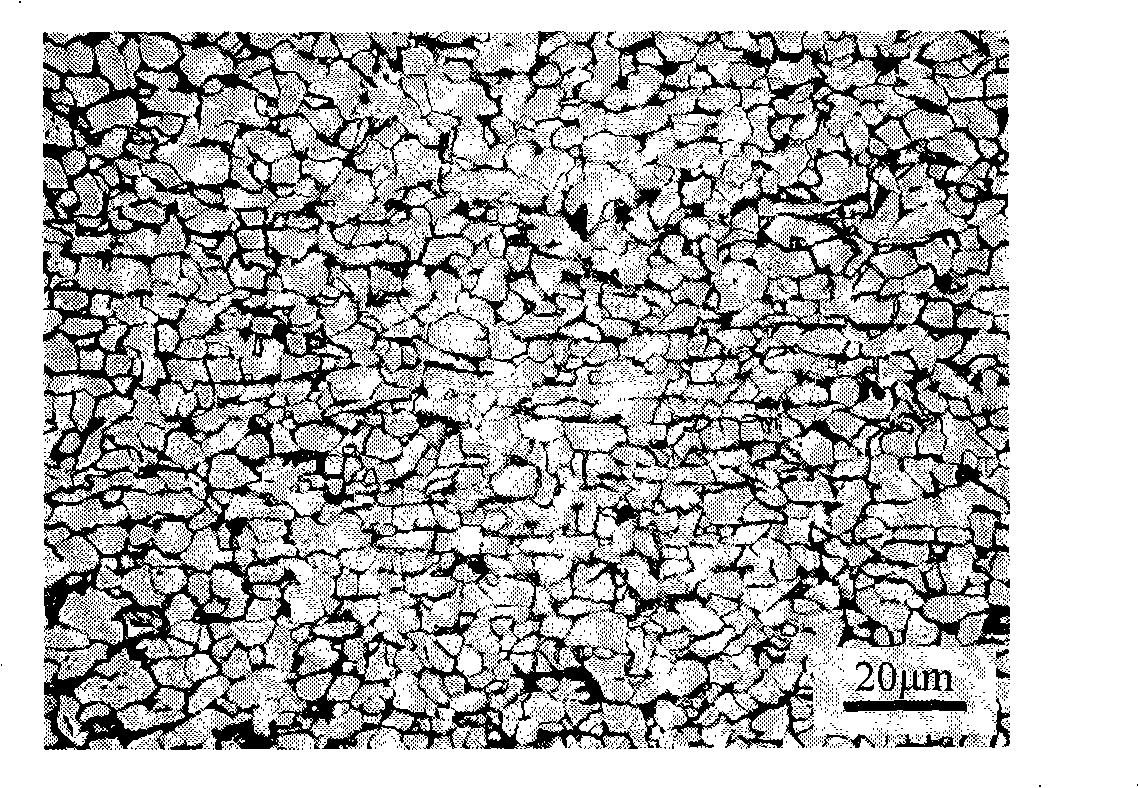

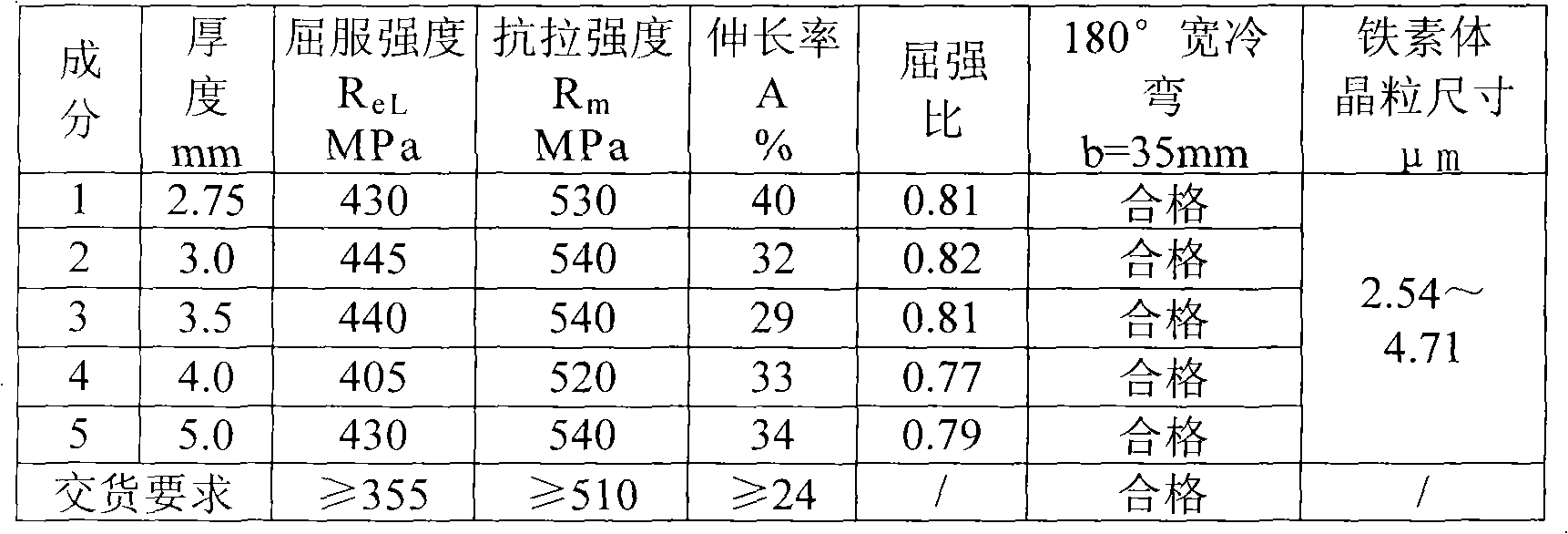

[0031] Table 3 lists the chemical compositions of five specific examples that the present invention can be used to produce ultra-fine carbon steel hot-rolled sheets. The production methods of these five ultra-fine carbon steels are as follows: top-bottom compound blowing is carried out on a 90-ton converter in a steelmaking plant, and hot metal desulfurization technology is used to make the S in the hot metal ≤ 0.005%, and the molten steel is treated with calcium to make the steel The chemical composition in it meets the requirements in Table 1 (see Table 3 for the actual composition), and the balance is Fe and unavoidable inclusions; then pour the molten steel with the composition shown in Table 3 into a slab with a section of 210-230mm×1150-1300mm. Then the slab is sent to the hot rolling plant, and the ultra-fine grain rolling process is used for hot rolling on a 1700mm rolling mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com