Production method for 40 kg class ship plate for large heat input welding

A large input energy welding and production method technology, applied in the field of iron and steel metallurgy, can solve problems such as reducing construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

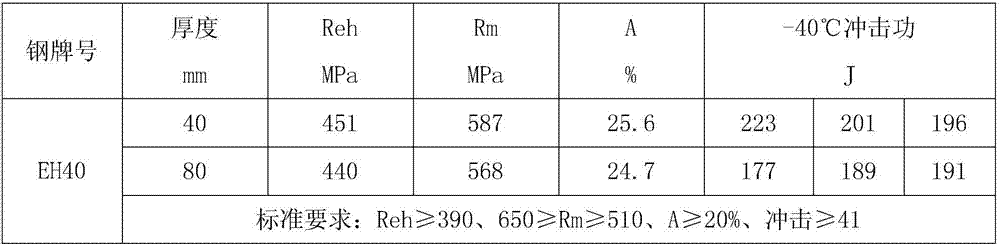

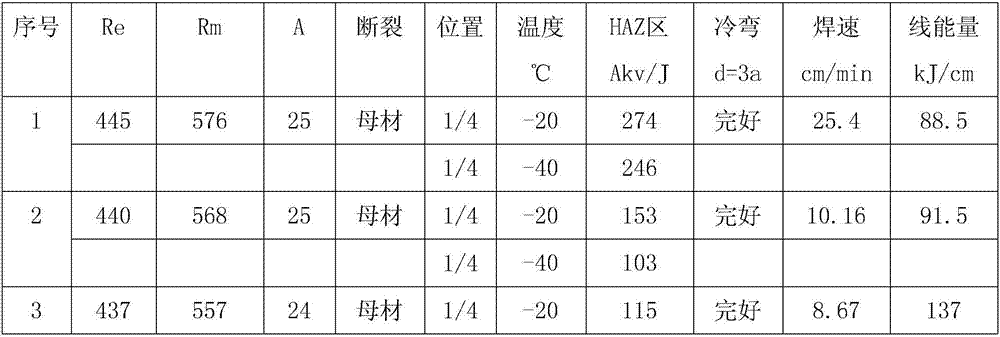

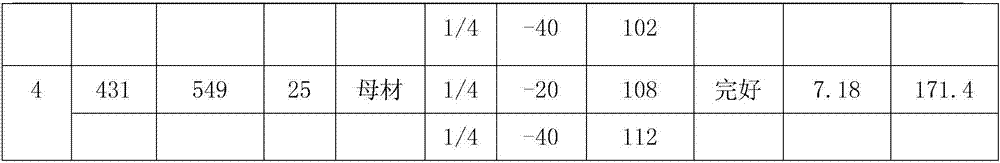

Examples

Embodiment 1

[0027] 1. The chemical composition weight percentages are: C: 0.075%, Si: 0.30%, Mn: 1.48%, Nb: 0.030%, Ti: 0.013%, Ni: 0.26%, Cu: 0.23%, Als: 0.025%, P≤ 0.020%, S≤0.005%, the rest are Fe and impurities; Ceq: 0.38%.

[0028] 2. Desulfurization of molten iron is carried out in steelmaking, the desulfurization slag is cleaned, the slag is blocked by the converter, and the thickness of the slag layer is 90mm; the ladle is kept clean and the alloy is fully roasted; the vacuum treatment pressure holding time is 15min.

[0029] 3. The target superheat degree of the tundish is controlled at 18°C; the pouring is protected throughout the whole process, and it is put into light pressing, and the continuous casting slabs are stacked and cooled slowly for 46 hours.

[0030] 4. The heating temperature of the billet is 1190℃, and the heating time is 9min / cm; after the billet is released from the furnace, go to the descaling machine to remove the scale.

[0031] 5. Two-stage rolling is adop...

Embodiment 2

[0035] 1. The chemical composition weight percentages are: C: 0.09%, Si: 0.25%, Mn: 1.52%, Nb: 0.025%, Ti: 0.015%, Ni: 0.22%, Cu: 0.28%, Als: 0.027%, P≤ 0.020%, S≤0.005%, the rest are Fe and impurities; Ceq: 0.38%.

[0036] 2. Desulfurization of molten iron is carried out in steelmaking, the desulfurization slag is cleaned, the slag is blocked by the converter, and the thickness of the slag layer is 80mm; the ladle is clean and the alloy is fully roasted; the RH molten steel circulation time is 16min.

[0037] 3. The target superheat degree of the tundish is controlled at 20 °C; the whole process is protected and poured, and it is put into light pressing, and the continuous casting slabs are stacked and cooled slowly for 48 hours.

[0038] 4. The heating temperature of the billet is 1210℃, and the heating time is 10min / cm; after the billet is released from the furnace, go to the descaling machine to remove the scale.

[0039] 5. Two-stage rolling is adopted for hot rolling, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com