Novel multi-purpose environment-friendly methanol-based alternative fuel and preparing method thereof

An alternative fuel, methanol fuel technology, used in fuels, fuel additives, liquid carbon-containing fuels and other directions, can solve the problems of methanol fuel low calorific value, short stability period, poor cold start, etc., to achieve long-term stable combustion, stable properties, Good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

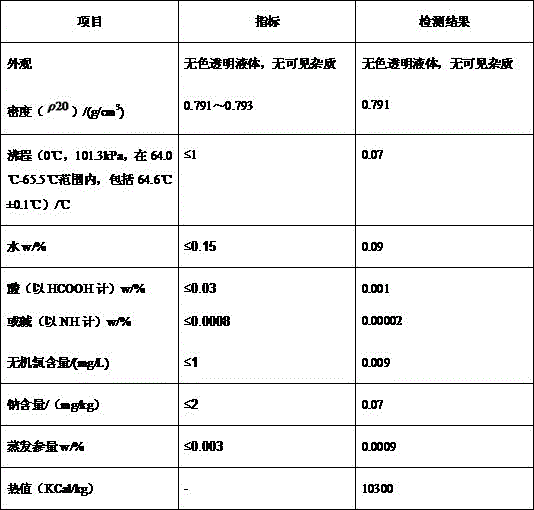

Embodiment 1

[0033] 85 parts of methanol; 5 parts of calorific value regulator; 2 parts of combustion stabilizer; 2 parts of combustion accelerator; 2 parts of thickening and curing agent; 2 parts of corrosion inhibitor; 2 parts of waterproofing agent.

[0034] Implementation steps:

[0035] (1) Weigh the calorific value regulator, combustion stabilizer, combustion accelerator, thickening and curing agent, corrosion inhibitor, and waterproofing agent in proportion, and mix them in an environment of 20-50°C, and use a stirring speed of Stir at 120-170r / min for 30-50min, then add a certain proportion of methanol, continue to stir at a constant speed for 5-10h, after fully stirring, put it in an ultrasonic processor with an ultrasonic frequency of 90-100KHz for processing 3-5h.

[0036] (2) Place the mixed material that has been stirred in step (1) in an environment with a temperature of -10--5°C for 3-5 hours, and place it in a vacuum filter for vacuum filtration, and then filter the obtain...

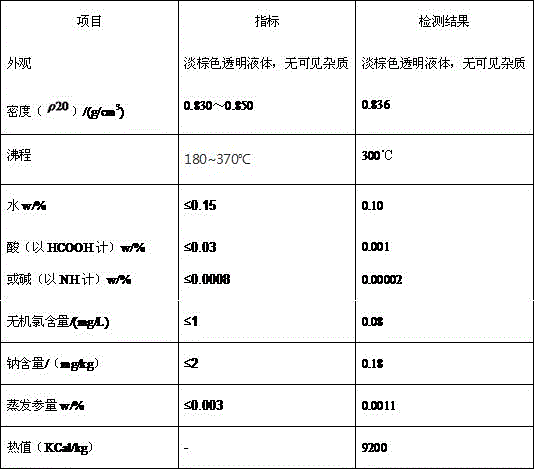

Embodiment 2

[0050] 90 parts of methanol; 5 parts of calorific value regulator; 1 part of combustion stabilizer; 1 part of combustion accelerator; 1 part of thickening and curing agent; 1 part of corrosion inhibitor; 1 part of waterproofing agent.

[0051] Implementation steps:

[0052] (1) Weigh the calorific value regulator, combustion stabilizer, combustion accelerator, thickening and curing agent, corrosion inhibitor, and waterproofing agent in proportion, and mix them in an environment of 20-50°C, and use a stirring speed of Stir at 120-170r / min for 30-50min, then add a certain proportion of methanol, continue to stir at a constant speed for 5-10h, after fully stirring, put it in an ultrasonic processor with an ultrasonic frequency of 90-100KHz for processing 3-5h.

[0053] (2) Place the mixed material that has been stirred in step (1) in an environment with a temperature of -10--5°C for 3-5 hours, and place it in a vacuum filter for vacuum filtration, and then filter the obtained U...

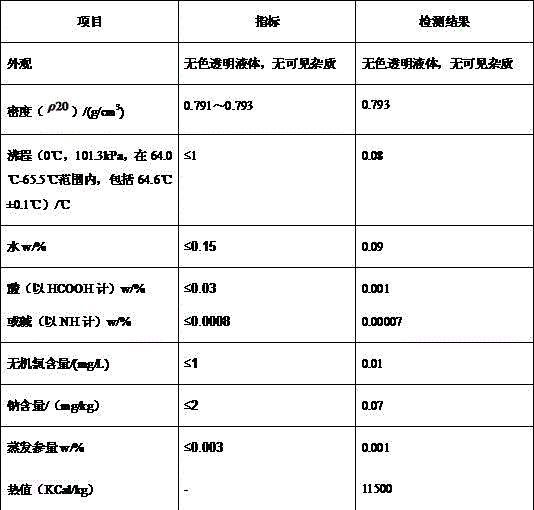

Embodiment 3

[0067] 95 parts of methanol; 5 parts of calorific value regulator; 0 parts of combustion stabilizer; 0 parts of combustion accelerator; 0 parts of thickening and curing agent; 0 parts of corrosion inhibitor; 0 parts of waterproofing agent.

[0068] Implementation steps:

[0069] (1) Weigh the calorific value regulator, combustion stabilizer, combustion accelerator, thickening and curing agent, corrosion inhibitor, and waterproofing agent in proportion, and mix them in an environment of 20-50°C, and use a stirring speed of Stir at 120-170r / min for 30-50min, then add a certain proportion of methanol, continue to stir at a constant speed for 5-10h, after fully stirring, put it in an ultrasonic processor with an ultrasonic frequency of 90-100KHz for processing 3-5h.

[0070] (2) Place the mixed material that has been stirred in step (1) in an environment with a temperature of -10--5°C for 3-5 hours, and place it in a vacuum filter for vacuum filtration, and then filter the obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com