Cold wire submerged-arc welding method and device, control system and control method

A submerged arc welding and control system technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of neglecting the thermal damage of the base metal, grain coarsening, affecting the welding quality and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

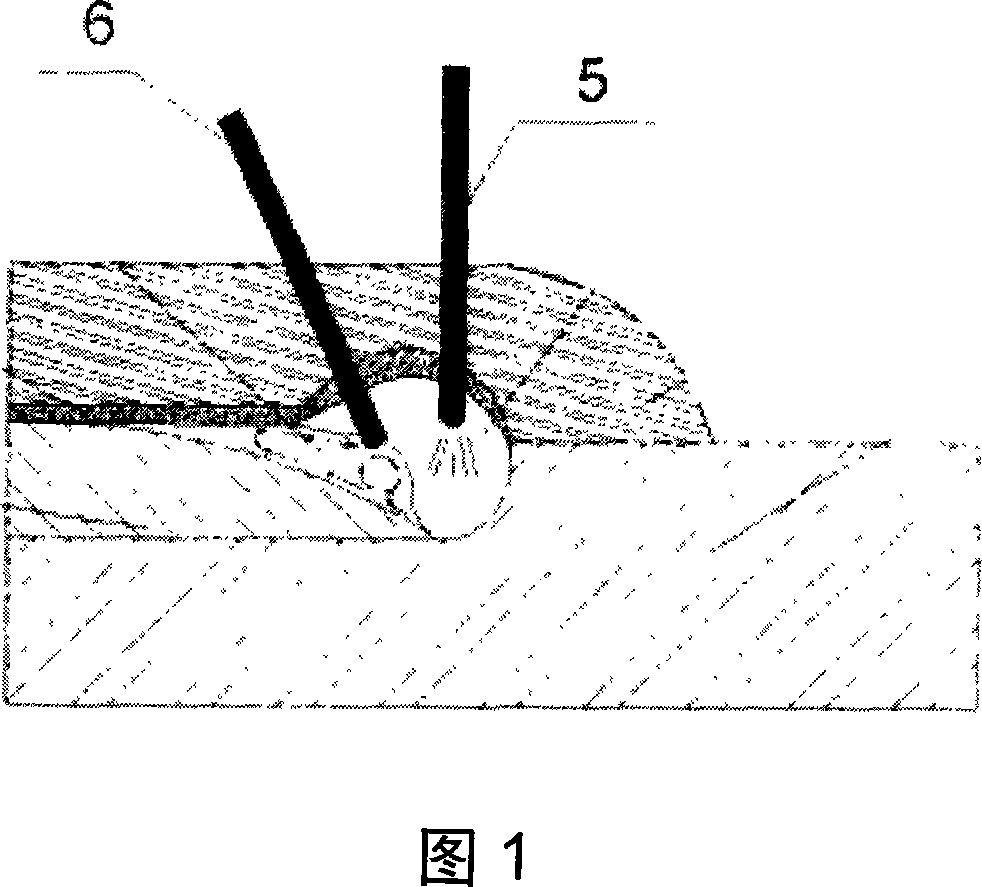

[0016] As shown in Figure 1, the cold wire submerged arc welding method of the present invention is to use the arc generated between the arc welding wire and the welded workpiece as the heat source, and insert a non-energized, non-heated cold wire into the overheated molten pool, As the weld filler metal, the filling position of the cold wire is located in the center of the high-temperature molten pool behind the arc center in the relative welding forward direction. Before the welding process is completed, first stop the feeding of the cold wire, and then extinguish the arc welding wire to end the whole welding process. welding process.

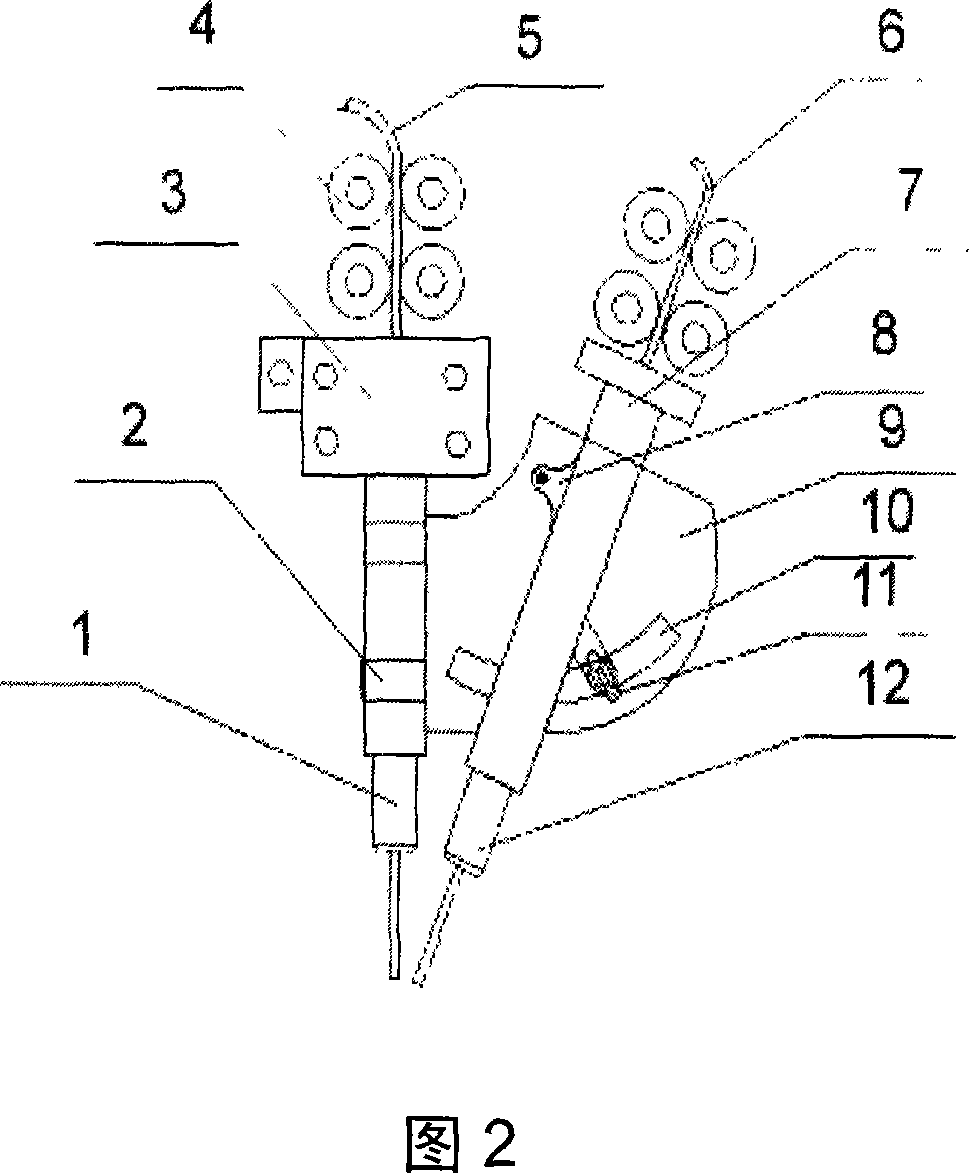

[0017] As shown in Figure 2, the cold wire submerged arc welding device of the present invention is fixedly installed on a conventional welding trolley, and is composed of a cold wire filling mechanism and an arcing wire feeding mechanism, and the arcing wire in the arcing wire feeding mechanism 5 is driven by two pairs of first wire feed rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com