Preparation method of double-faced transmission tooth-wedge belt

A technology of transmission teeth and wedge belt, applied in the field of preparation of double-sided transmission tooth wedge belt, can solve the problems of complex processing technology of wedge belt, poor forming effect, poor integrity of wedge belt, etc. good integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

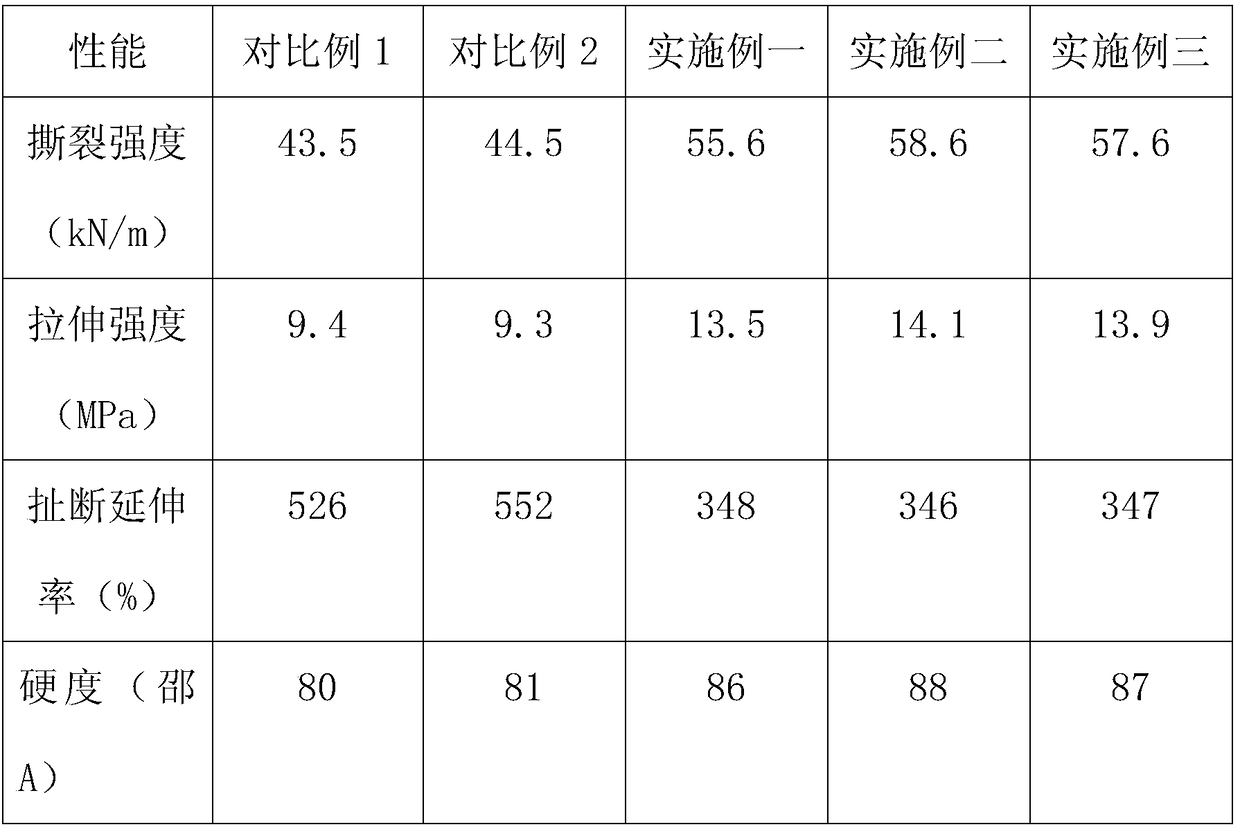

Embodiment 1

[0027] The preparation method of a kind of double-sided transmission tooth wedge belt proposed by the present invention comprises the following steps,

[0028] S1, prepare raw materials, including the following raw materials in parts by weight: 120-140 parts of ethylene-propylene rubber, 15 parts of non-cellulose fiber, 5 parts of short fiber, 15 parts of neoprene rubber, 15 parts of ultra-high molecular weight polyethylene, and 3 parts of adhesive 1 part, vulcanizing agent 1 part, anti-aging agent 1 part, crosslinking agent 1 part, auxiliary crosslinking agent 0.5 part, reinforcing agent 1 part, softener 1 part, accelerator 3 parts, dispersant 1 part, lubricant 2 parts , 1 part of organic filler, 1 part of nano inorganic filler, 1.3 parts of flame retardant additive, 1.3 parts of flame retardant synergist, 1 part of flame retardant, 1 part of heat stabilizer, 1 part of carbon black;

[0029] S2, add ethylene-propylene rubber, non-cellulose fiber, short fiber, neoprene, adhesi...

Embodiment 2

[0036] The preparation method of a kind of double-sided transmission tooth wedge belt proposed by the present invention comprises the following steps,

[0037] S1, preparing raw materials, including the following raw materials in parts by weight: 130 parts of ethylene-propylene rubber, 17.5 parts of non-cellulose fiber, 6.5 parts of short fiber, 17.5 parts of neoprene rubber, 17.5 parts of ultra-high molecular weight polyethylene, 4 parts of adhesive, 2 parts of vulcanizing agent, 3 parts of anti-aging agent, 2 parts of cross-linking agent, 0.65 parts of auxiliary cross-linking agent, 3 parts of reinforcing agent, 3 parts of softening agent, 4 parts of accelerator, 3 parts of dispersing agent, 3.5 parts of lubricant, organic 12 parts of filler, 12 parts of nano inorganic filler, 1.5 parts of flame retardant additive, 1.5 parts of flame retardant synergist, 1.5 parts of flame retardant, 1.5 parts of heat stabilizer, 2 parts of carbon black;

[0038]S2, add ethylene-propylene ru...

Embodiment 3

[0045] The preparation method of a kind of double-sided transmission tooth wedge belt proposed by the present invention comprises the following steps,

[0046] S1, preparing raw materials, including the following raw materials in parts by weight: 140 parts of ethylene-propylene rubber, 20 parts of non-cellulose fibers, 8 parts of short fibers, 20 parts of neoprene rubber, 20 parts of ultra-high molecular weight polyethylene, 5 parts of adhesive, 3 parts of vulcanizing agent, 5 parts of anti-aging agent, 3 parts of cross-linking agent, 0.8 parts of auxiliary cross-linking agent, 5 parts of reinforcing agent, 5 parts of softening agent, 5 parts of accelerator, 5 parts of dispersing agent, 5 parts of lubricant, organic 20 parts of fillers, 20 parts of nano-inorganic fillers, 1.7 parts of flame retardant additives, 1.7 parts of flame retardant synergists, 3 parts of flame retardants, 3 parts of heat stabilizers, and 3 parts of carbon black;

[0047] S2, add ethylene-propylene rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com