Oriented fiber aerogel heat-insulating compound material and preparation method thereof

A composite material and aerogel technology, which is applied in the field of thermal insulation composite materials, can solve the problems of airgel performance impact and unclear improvement, and achieve the effects of flexible structure controllability, weight reduction, and improved damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

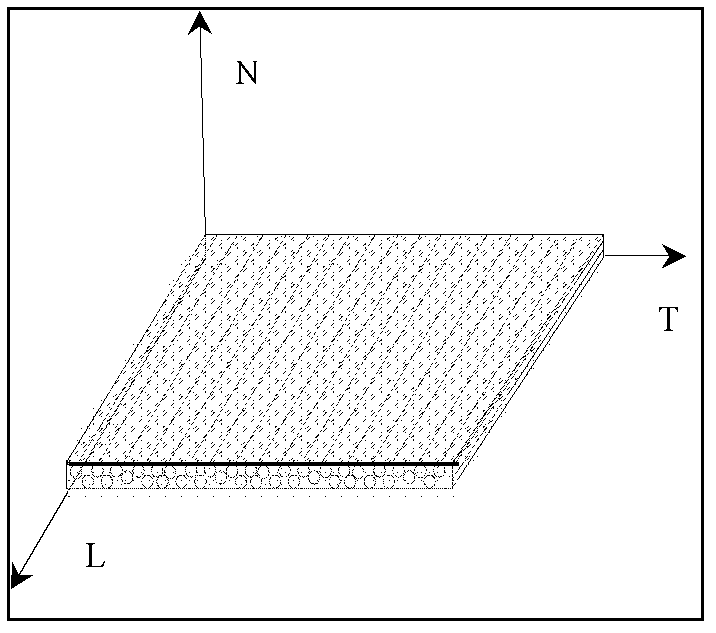

[0056] An oriented fiber airgel thermal insulation composite material, comprising at least one layer of fiber skeleton and airgel, the airgel is filled between the fiber skeleton; the fibers in the fiber skeleton are arranged neatly in the same direction, which is oriented Fibrous skeleton.

[0057] The oriented fiber airgel thermal insulation composite material not only has good mechanical properties but also effectively maintains the super thermal insulation performance of the airgel, and can be used in any field requiring thermal insulation protection measures.

Embodiment 2

[0059] An oriented fiber airgel thermal insulation composite material comprises a fiber skeleton and airgel, the airgel is filled between the fiber skeletons; the fibers in the fiber skeleton are arranged neatly in the same direction, which is an oriented fiber skeleton.

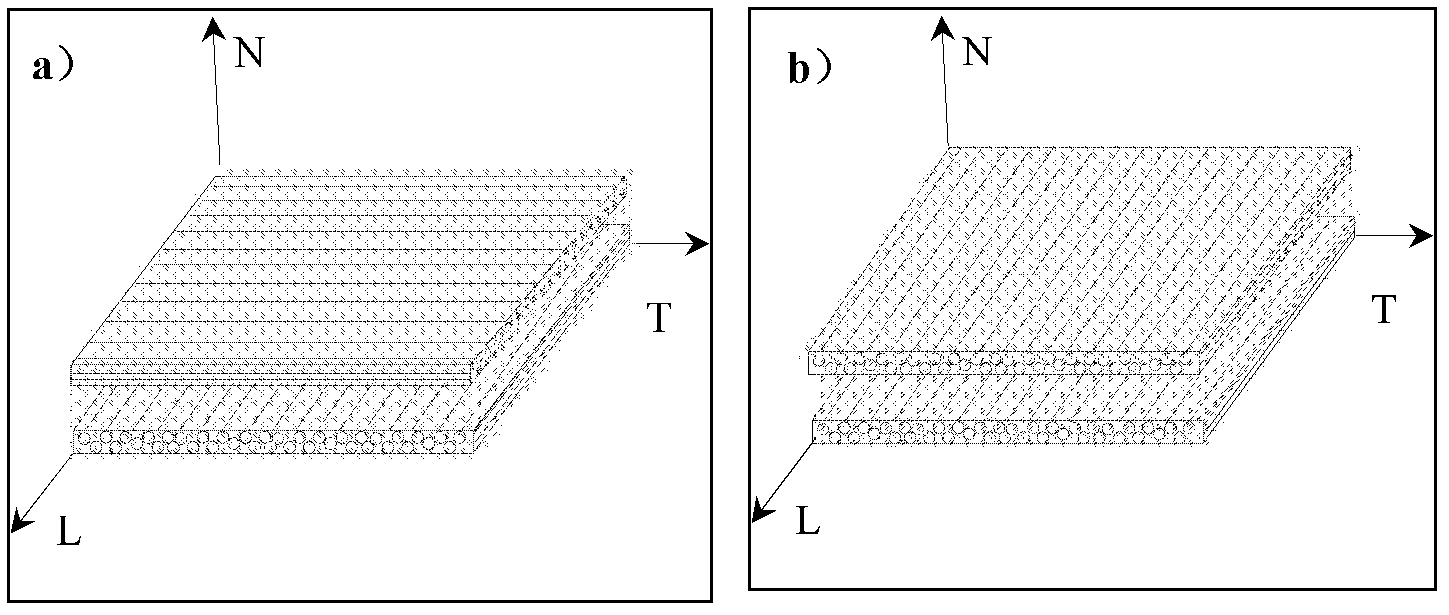

[0060] The oriented fiber skeleton has two layers.

[0061] The fibers in the fiber skeleton are glass fibers with an aspect ratio of 5000 and a fiber diameter of 20 μm.

[0062] The orientation directions between the oriented fiber skeleton layers are respectively placed in the same direction and placed in the orthogonal direction, and the finished products are respectively as follows: Figure 7 Figures a and b show.

[0063] The airgel is a silica airgel, and its preparation step is, first, use an acidic solvent to decompose the mixed solution of silicon alkoxide, alcohol solvent, and water with an acidic catalyst, and the silicon alkoxide described in this embodiment is positive Ethyl silicate (TEOS), d...

Embodiment 3

[0065] An oriented fiber airgel thermal insulation composite material comprises a fiber skeleton and airgel, the airgel is filled between the fiber skeletons; the fibers in the fiber skeleton are arranged neatly in the same direction, which is an oriented fiber skeleton.

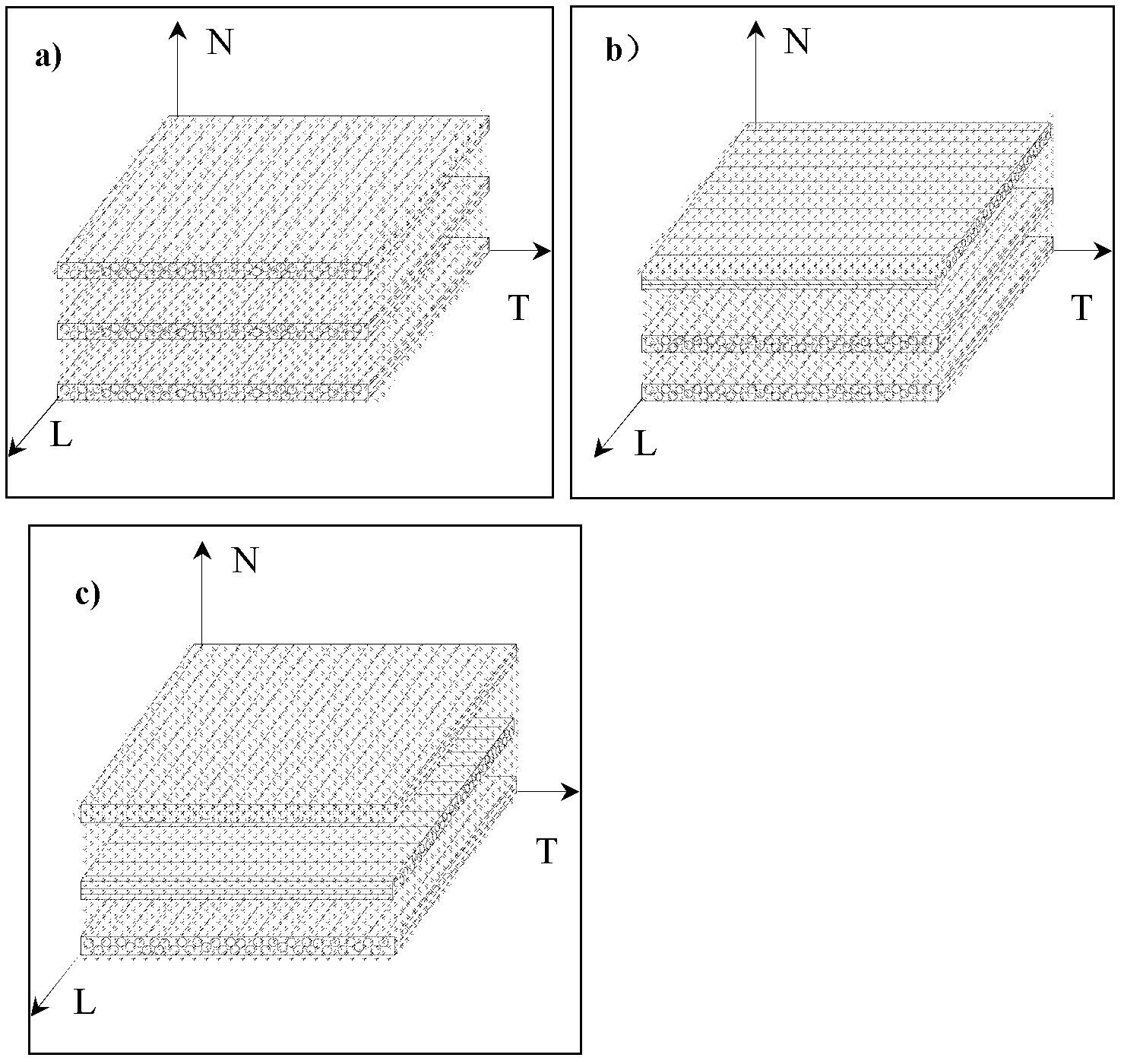

[0066] The oriented fiber skeleton has four layers.

[0067] The fibers in the fiber skeleton are glass fibers with an aspect ratio of 5000 and a fiber diameter of 20 μm.

[0068] The orientation directions between the oriented fiber skeleton layers are placed in the same direction and placed in the orthogonal direction respectively, and the specific directions are as follows: Figure 4 Figures a to f are shown.

[0069] The airgel is a silica airgel, and its preparation step is, first, use an acidic solvent to decompose the mixed solution of silicon alkoxide, alcohol solvent, and water with an acidic catalyst, and the silicon alkoxide described in this embodiment is positive Ethyl silicate (TEOS), describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com