Waterborne acrylic alkyd resin and preparation method and application thereof

A technology of acrylic alkyd and acrylic acid, applied in the chemical field, can solve the problems affecting the dryness, hardness, gloss and water resistance of the coating film, and achieve the effects of improving hydrolysis stability, good hydrolysis resistance and high storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

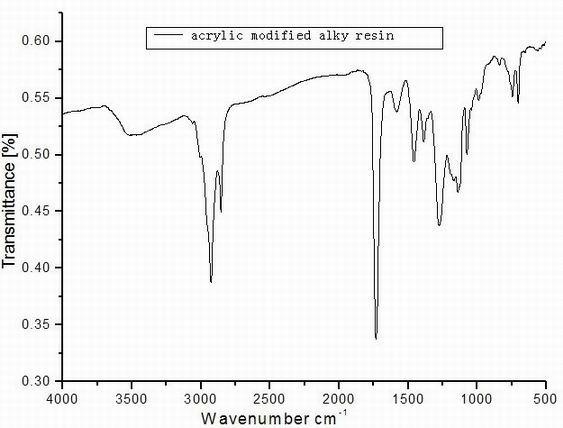

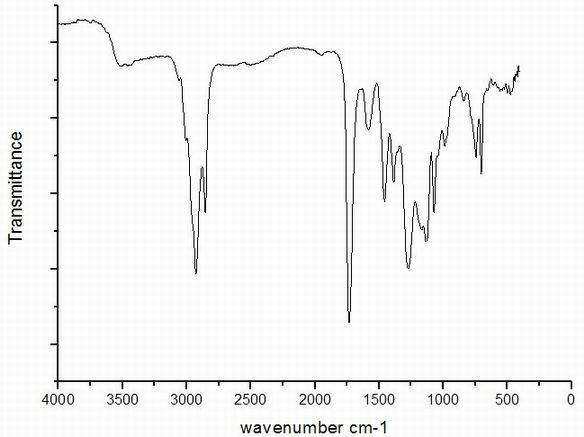

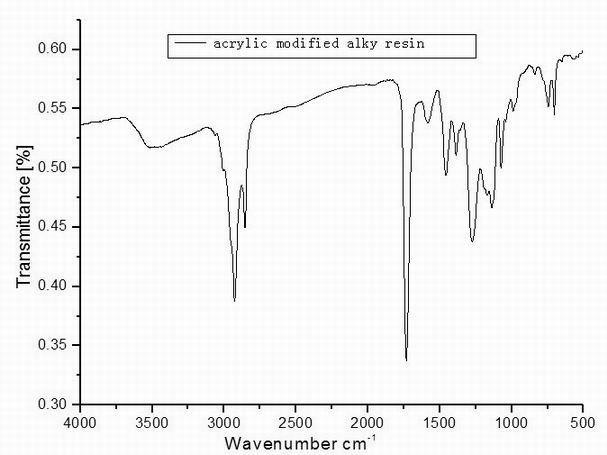

Image

Examples

Embodiment 1

[0038] The preparation of embodiment 1 aqueous acrylic alkyd resin emulsion

[0039] Add 100ml of organic solvent butyl acetate into a four-necked flask equipped with mechanical stirring, reflux condenser, and 2 constant pressure dropping funnels, pass nitrogen gas for 30min and heat to 105°C, then separate the acrylic monomer and initiator and The chain transfer agent is placed in two constant-pressure dropping funnels, and dripped at a constant speed within 3.5 hours at a constant temperature. Insulate and react for 1.5 hours, cool down to room temperature, and store the obtained acrylic acid prepolymer for future use. The consumption of four kinds of acrylic acid monomers is: methyl methacrylate 35.0g, butyl methacrylate 45.0g, methacrylic acid 10g, acrylic acid 12.5g; Initiator is azobisisobutyronitrile (AIBN), and its consumption is 0.4wt% of the total amount of the four acrylic monomers, the chain transfer agent is dodecyl mercaptan, and its amount is 8wt% of the total ...

Embodiment 2

[0041] The preparation of embodiment 2 aqueous acrylic alkyd resin emulsions

[0042] Add 105ml of xylene into a four-neck flask equipped with mechanical stirring, reflux condenser, and two constant pressure dropping funnels, pass nitrogen gas for about 30min and heat to 100°C, then separate the four acrylic acid monomer mixtures (methacrylic acid 35.0 g of methyl ester, 40.0 g of ethyl methacrylate, 12 g of methacrylic acid, 10 g of acrylic acid, azobisisobutyronitrile (AIBN): 0.2 wt%) and chain transfer agent (dodecyl mercaptan: 10 wt%) Put it in two constant pressure dropping funnels, and drop it at a constant speed for 3 hours at a constant temperature. Insulate and react for 1.5 hours, cool down to room temperature, and store the obtained acrylic acid prepolymer for future use.

[0043] Add 20.8g of tung oil, 8.6g of pentaerythritol, and 0.12g of lithium hydroxide into a four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, pass nitrogen gas f...

Embodiment 3

[0045] Storage stability and hydrolysis resistance of aqueous acrylic alkyd resin emulsion of the present invention

[0046] The aqueous acrylic alkyd resin emulsion prepared in Example 1 was placed in a 25°C incubator, and its pH value was tested to be 7.5 after storage for 6 months, and the viscosity change (coating -4 cups) was less than 5%. The test results show that the aqueous acrylic alkyd resin emulsion has good storage stability and hydrolysis resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com