Preparation method of nano SiO2/ACR composite particles and application thereof

A composite particle and nano-technology, which is applied in the preparation and application of nano-SiO2/ACR composite particles, can solve the problems of high price, late start, small proportion, etc., and achieve good dispersion, mechanical properties, and excellent impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

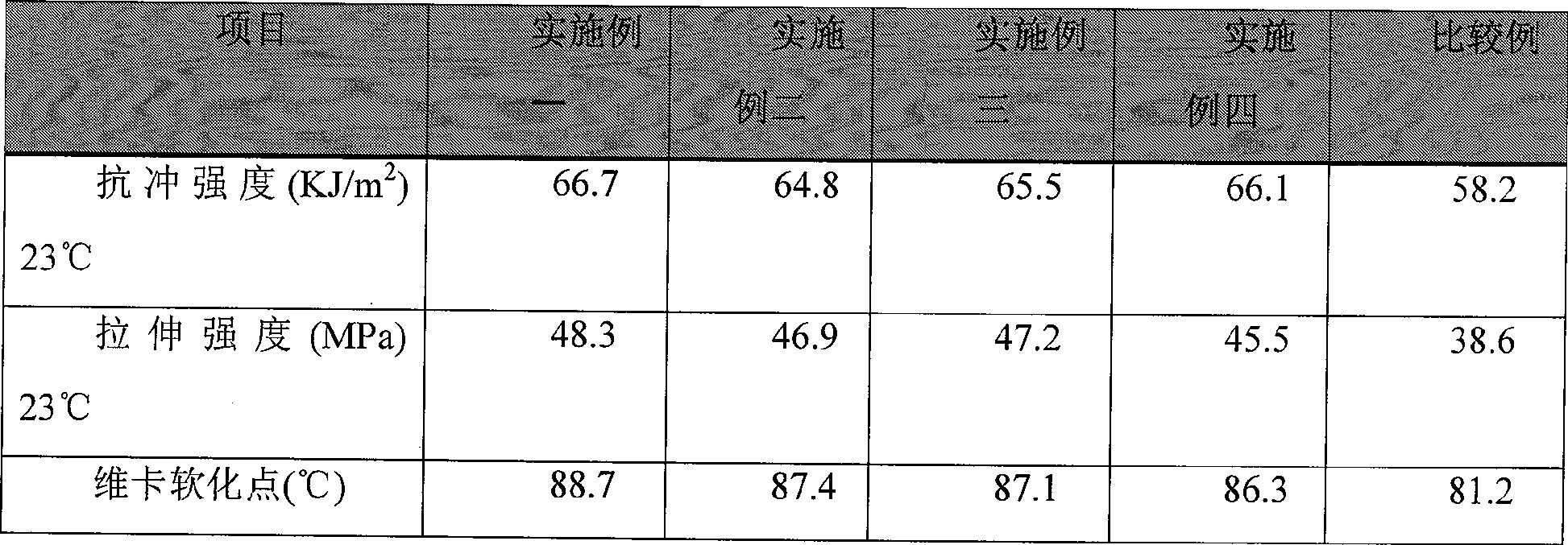

Examples

Embodiment 1

[0021] (1) Mechanical stirring and ultrasonic-assisted pre-emulsification reaction monomer: sodium dodecylbenzenesulfonate / alkylphenol polyoxyethylene ether (mass ratio is 70:30), the content of the compound emulsifier in the preparation of seed latex is monomer 1.5% of the mass, the amount of compound emulsifier used in the preparation of the inner core is 0.4% of the mass of the monomer, and the amount of the compound emulsifier used in the preparation of the shell is 0.1% of the mass of the monomer;

[0022] (2) seed latex preparation: with ethyl acrylate as monomer, be 0.6% of all reaction monomer quality, potassium persulfate (KPS) initiator consumption is 0.3% of monomer quality;

[0023] (3) Inner core preparation: the monomer mass ratio of butyl methacrylate: ethyl acrylate is 80:20, and the amount of composite crosslinking agent is 0.08% of the monomer mass, among which, N,N'-methylenebisacrylamide :CH 2 =CHRCH 2 COOR'(R is n-C 10 h 21 , R' is -CH 3 ) mass ratio ...

Embodiment 2

[0028] (1) The mass ratio of the compound emulsifier sodium alkylnaphthalene sulfonate / Span 60 is 80:20, the content of the compound emulsifier in the preparation of the seed latex is 1.0% of the monomer mass, and the amount of the compound emulsifier in the preparation of the kernel is the monomer mass 0.5% of the compound emulsifier used in shell preparation is 0.06% of the monomer mass;

[0029] (2) ethyl acrylate monomer is 0.5% of all reaction monomer quality, and potassium persulfate (KPS) is 0.3% of monomer quality as initiator consumption;

[0030] (3) The monomer mass ratio of butyl methacrylate: ethyl acrylate is 70:30, and the amount of composite crosslinking agent is 0.06% of the monomer mass, wherein, N, N'-methylenebisacrylamide: CH 2 =CHRCH 2 COOR'(R is n-C 8 h 17 , R' is n-C 4 h 9 ) mass ratio is 80:20, potassium persulfate (KPS) initiator consumption is 0.2% of monomer mass;

[0031] (4) The siloxane coupling agent is ethylenediaminopropyltrimethoxysilan...

Embodiment 3

[0035] (1) The mass ratio of the compound emulsifier sodium dodecylbenzenesulfonate / fatty alcohol polyoxyethylene ether is 60:40, the content of the compound emulsifier in the preparation of the seed latex is 1.3% of the monomer mass, and the compound emulsifier in the preparation of the kernel The dosage is 0.3% of the mass of the monomer, and the dosage of the composite emulsifier in the preparation of the shell is 0.05% of the mass of the monomer;

[0036] (2) ethyl acrylate monomer is 0.8% of all reaction monomer quality, and potassium persulfate (KPS) is 0.4% of monomer quality as initiator consumption;

[0037] (3) The monomer mass ratio of butyl methacrylate: ethyl acrylate is 90:10, and the amount of composite crosslinking agent is 0.05% of the monomer mass, wherein, N, N'-methylenebisacrylamide: CH 2 =CHRCH 2 COOR'(R is n-C 12 h 25 , R' is n-C 2 h 5 ) mass ratio is 70:30, potassium persulfate (KPS) initiator consumption is 0.16% of monomer mass;

[0038] (4) The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com