Fatty alcohol polyoxypropylene polyoxyethylene ether carboxylate, preparation thereof and application thereof

A technology of alcohol polyoxypropylene polyoxyethylene ether carboxylate and polyoxypropylene polyoxyethylene ether carboxylate is applied in the field of fatty alcohol polyoxypropylene polyoxyethylene ether carboxylate and its preparation and application, and can solve the problem of Difficulty in selecting fatty alcohols and other problems to achieve the effect of enhancing lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

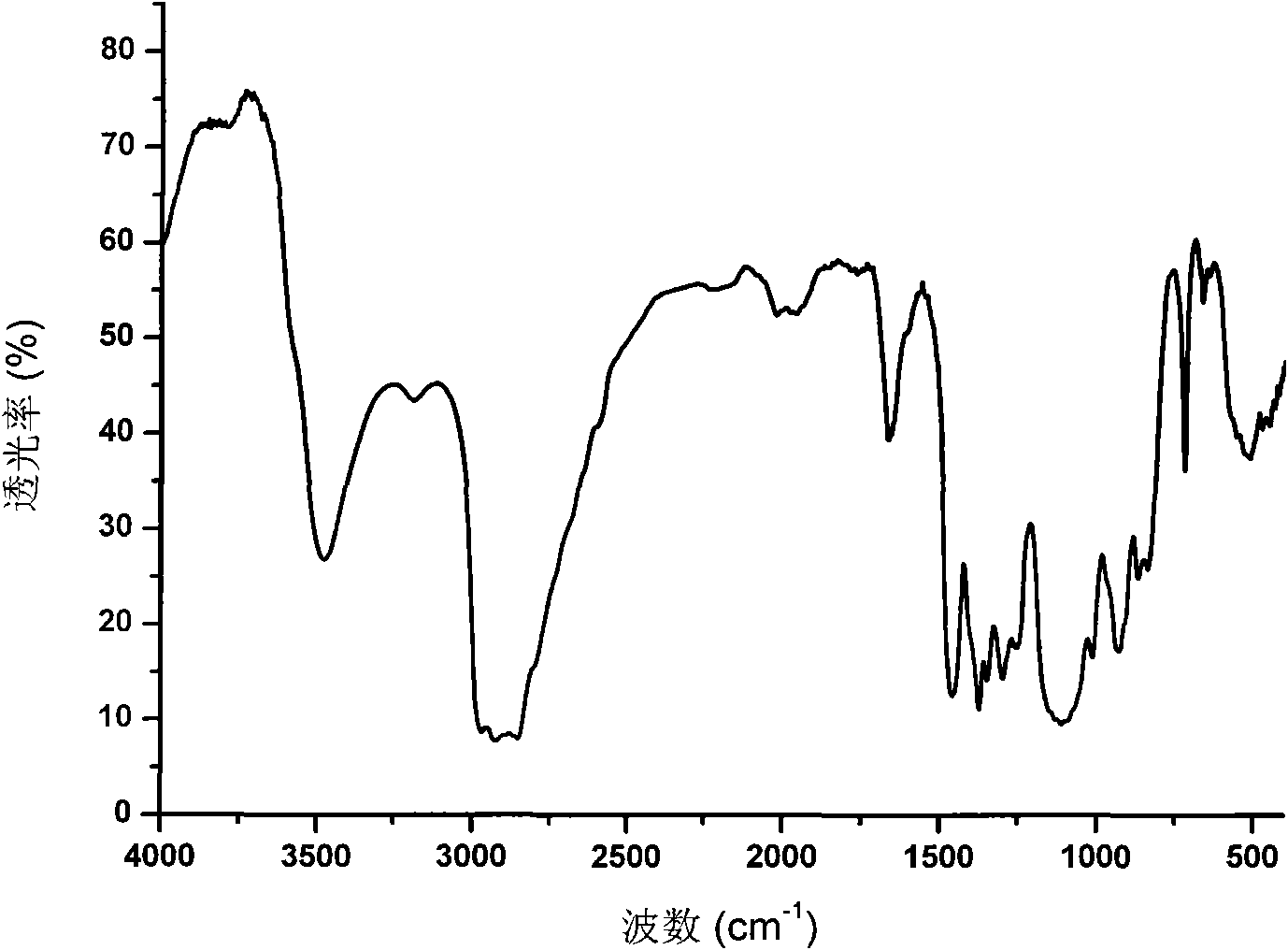

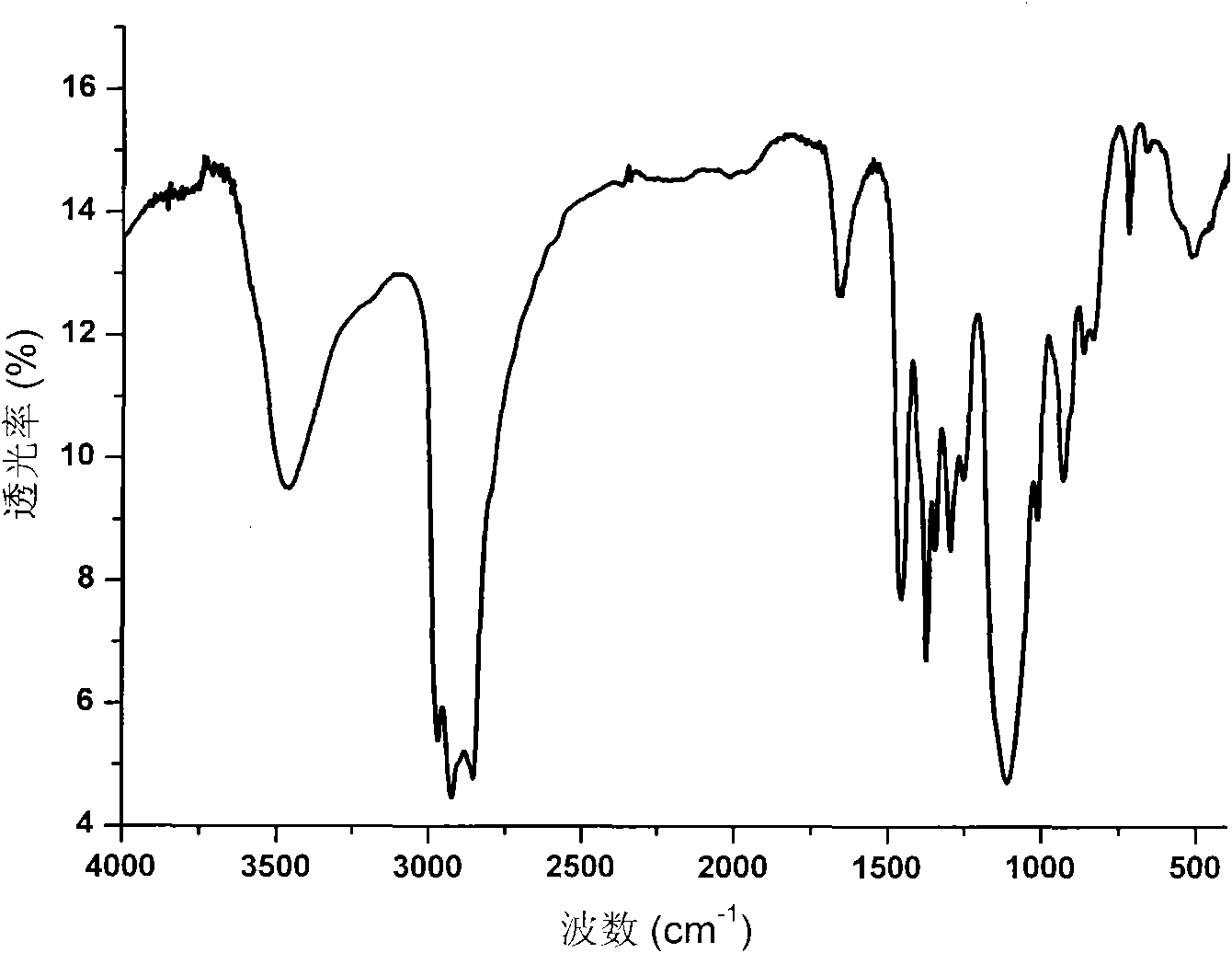

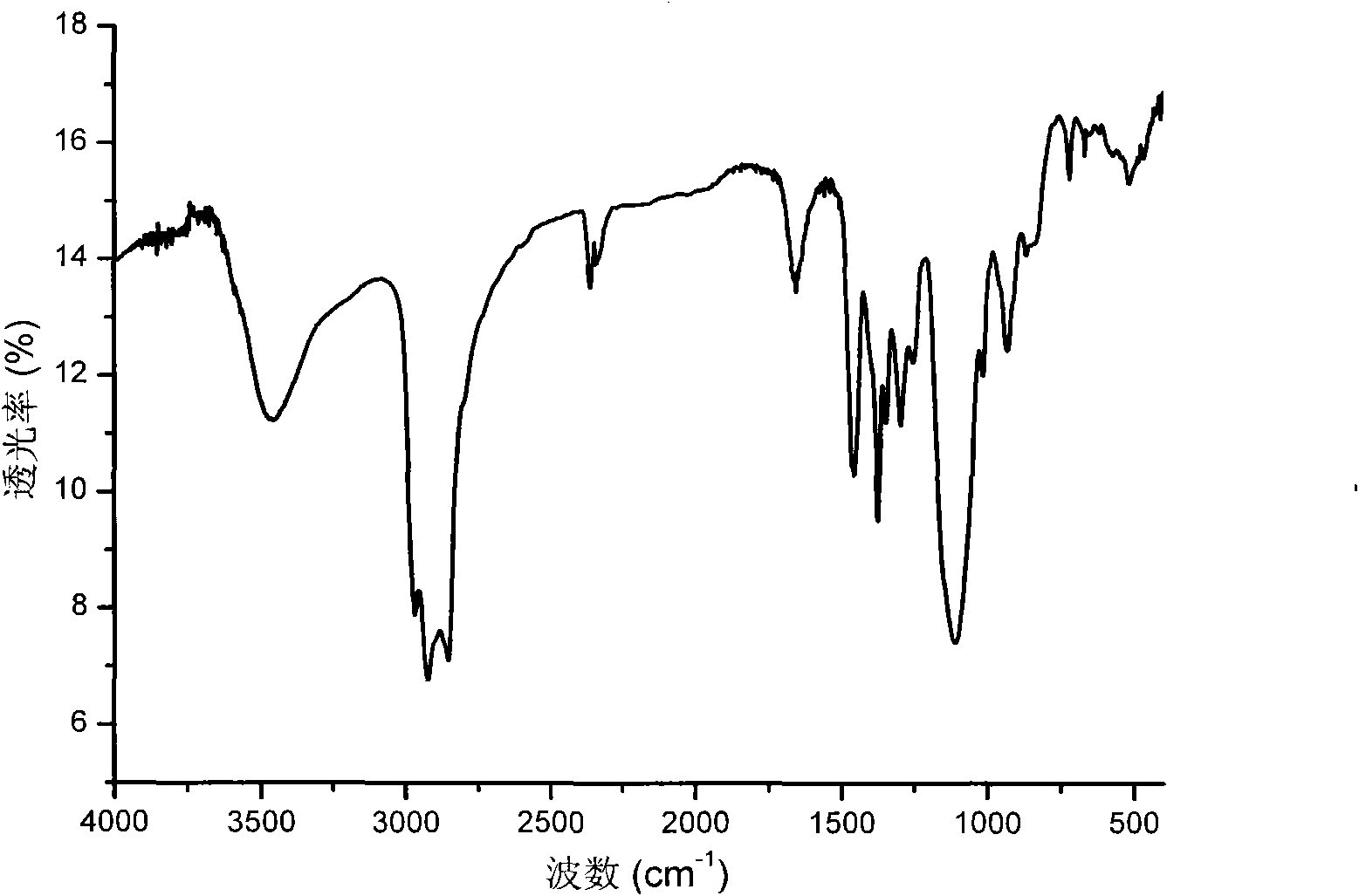

[0047] synthetic compound

[0048] 1. Synthetic reaction of fatty alcohol polyoxypropylene polyoxyethylene ether

[0049] The fatty alcohol here is fatty alcohol or alkylphenol with a total C length of 8-22, which can be straight chain or branched, preferably straight chain, and the required PO length and EO length can be obtained through the raw material ratio.

[0050]Add a certain amount of fatty alcohol and powdered potassium hydroxide into the high-pressure reactor, stir, and feed N when the temperature rises to 50-60°C. 2 Make protective gas, continue to heat up to about 120 ℃. in N 2 Propylene oxide was added under protection for two hours. After the addition was complete, the temperature was raised to 140°C, and the reaction was carried out at a constant temperature for two hours. Then, it was naturally cooled to room temperature to obtain fatty alcohol polyoxypropylene ether.

[0051] Add a certain amount of fatty alcohol polyoxypropylene ether and powdered potassi...

Embodiment 2

[0066] Application in Tertiary Oil Recovery

[0067] The US Texas-500 interfacial tensiometer was selected, and the interfacial tension was measured by the spin drop method. The crude oil measured is Xinjiang Karamay crude oil.

[0068] Table 1: C 16 PO 8 EO 2 CH 2 Interfacial tension values of COOK at different weak base concentrations

[0069]

[0070] Table 2: C 18 PO 10 EO 3 CH 2 Interfacial tension values of COOK at different weak base concentrations

[0071]

[0072] Table 1 for 0.3% C 16 PO 8 EO 2 CH 2 COOK in different weak bases (Na 2 CO 3 ) concentration of interfacial tension in crude oil. in Na 2 CO 3 When the concentration is 0.2% to 0.4%, the surfactant quickly reaches an ultra-low interfacial tension value.

[0073] Table 2 for 0.3% C 18 PO 10 EO 3CH 2 COOK in different weak bases (Na 2 CO 3 ) concentration in crude oil interfacial tension value, in Na 2 CO 3 At higher concentrations, the surfactant quickly reaches an ultra-l...

Embodiment 3

[0075] Natural outcrop cores with a length of 30 cm and a diameter of 3.8 cm were selected indoors to evaluate the displacement efficiency of weak alkali combined flooding. The tensio-active agent of weak base composite system adopts the C in the embodiment (2) 16 PO 8 EO 2 CH 2 COOK and C 18 PO 10 EO 3 CH 2 COOK, the polymer uses 25 million polyacrylamide HPAM, and the crude oil is Xinjiang dehydrated crude oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com