Infrared hot air drying method of fistular onion stalks pretreated through union of vacuum and ethanol

A hot air drying and pretreatment technology, applied in food drying, application, food preservation, etc., can solve the problems of long drying time, complicated equipment operation, short storage period, etc., to improve the efficiency of osmotic dehydration, solve environmental pollution, increase ventilation The effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

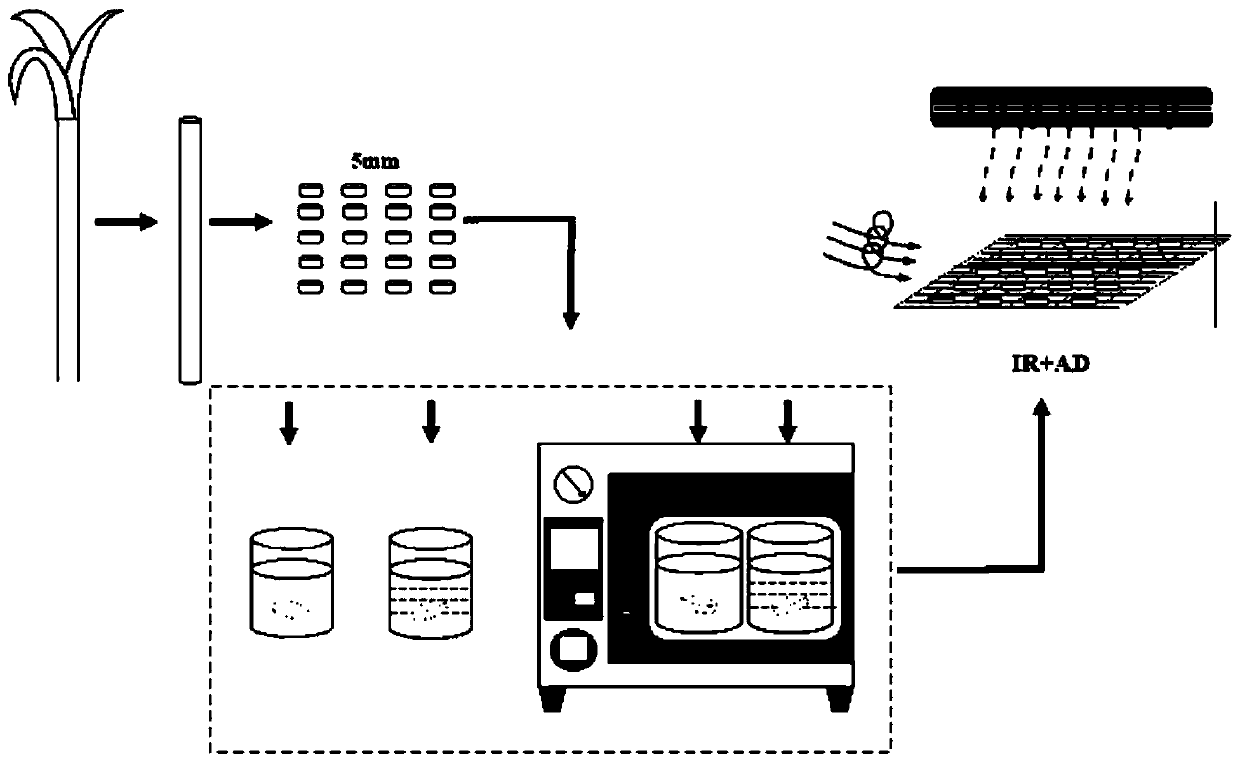

Method used

Image

Examples

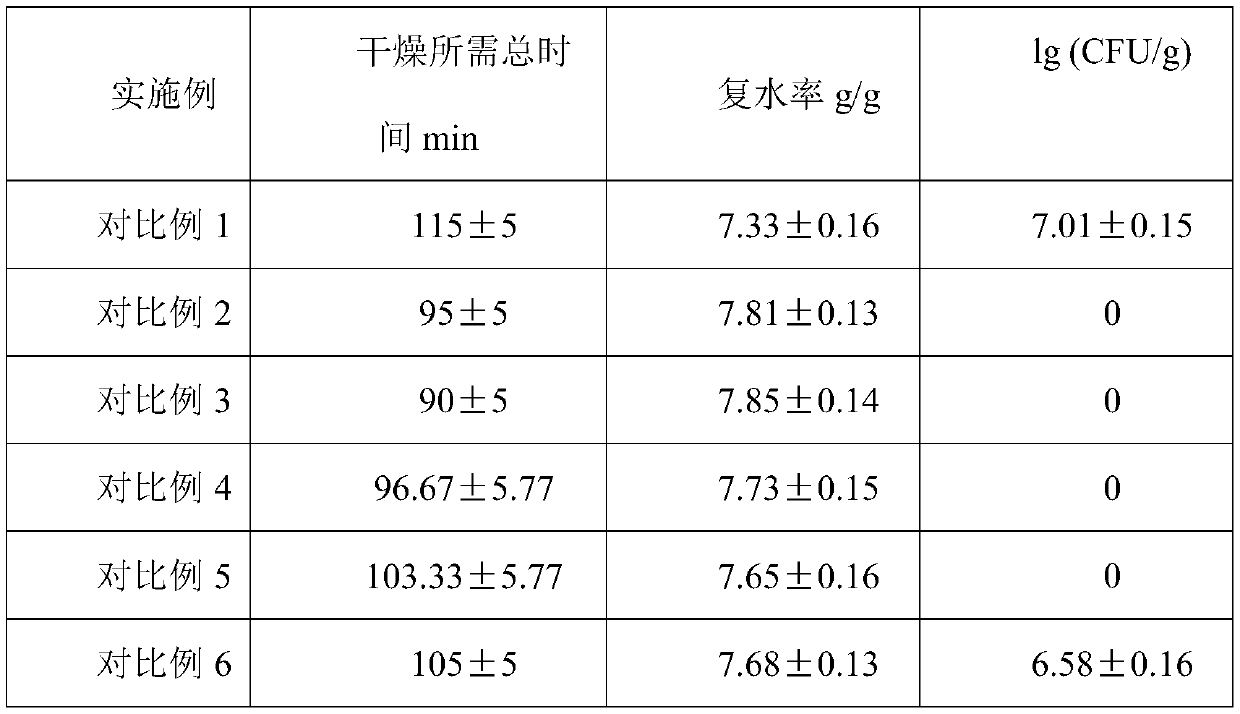

Embodiment 1

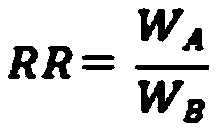

[0048] Select fresh scallions with no mechanical damage on the surface and no pests to remove the outer skin, wash, and cut into sections with a thickness of 5mm. Place them in 75% ethanol at 25°C and put them in a vacuum with a vacuum degree of 0.3bar. Vacuum treatment in the box for 10 minutes, and then carry out infrared hot air drying at a drying temperature of 60°C and a wind speed of 2m / s, and stop drying when the water content of the scallion white is lower than 7%, to obtain the final scallion ring sample. Determination of rehydration and microbial content of scallions after drying. For the specific detection method, refer to Comparative Example 1.

Embodiment 2

[0050] Select fresh scallions with no mechanical damage on the surface and no pests to remove the outer skin, wash, and cut into sections with a thickness of 5mm. Place them in 80% ethanol at 25°C and put them in a vacuum with a vacuum degree of 0.6bar at the same time. Vacuum treatment in the box for 10 minutes, and then carry out infrared hot air drying at a drying temperature of 60°C and a wind speed of 2m / s, and stop drying when the water content of the scallion white is lower than 7%, to obtain the final scallion ring sample. Determination of rehydration and microbial content of scallions after drying. For the specific detection method, refer to Comparative Example 1.

Embodiment 3

[0052] Select fresh scallions with no mechanical damage on the surface and no pests to remove the outer skin, wash, and cut into sections with a thickness of 5mm. Place them in 85% ethanol at 25°C and put them in a vacuum with a vacuum degree of 0.6bar. Vacuum treatment in the box for 10 minutes, and then carry out infrared hot air drying at a drying temperature of 60°C and a wind speed of 2m / s, and stop drying when the water content of the scallion white is lower than 7%, to obtain the final scallion ring sample. Determination of rehydration and microbial content of scallions after drying. For the specific detection method, refer to Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com