Plant extract decolorizing device

A plant extract and decolorization technology, which is applied in the field of plant extract decolorization devices, can solve the problems of difficult separation, reduce the practicability of the decolorization device, and mix together, and achieve the effect of improving practicability, increasing the degree of mixing, and improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

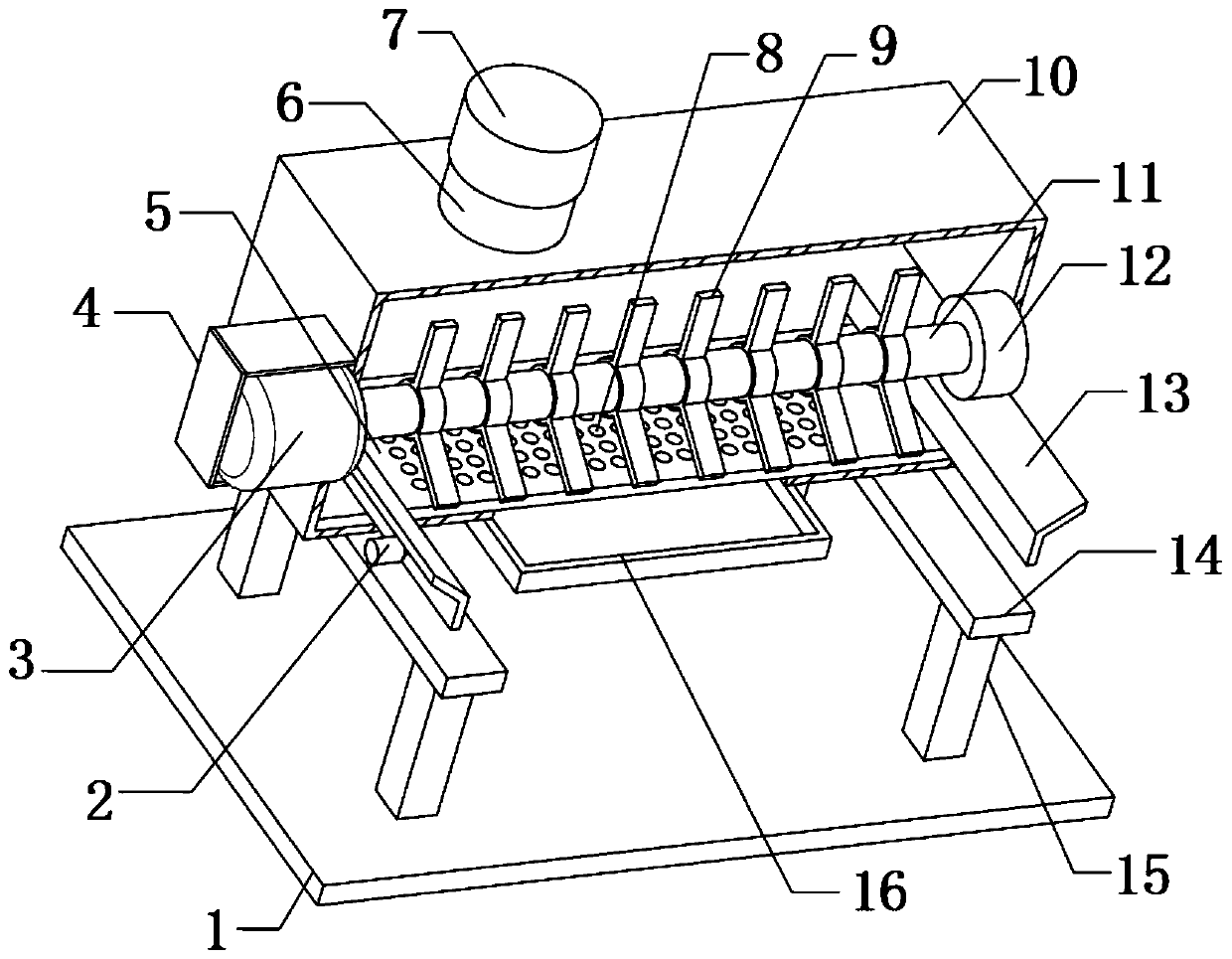

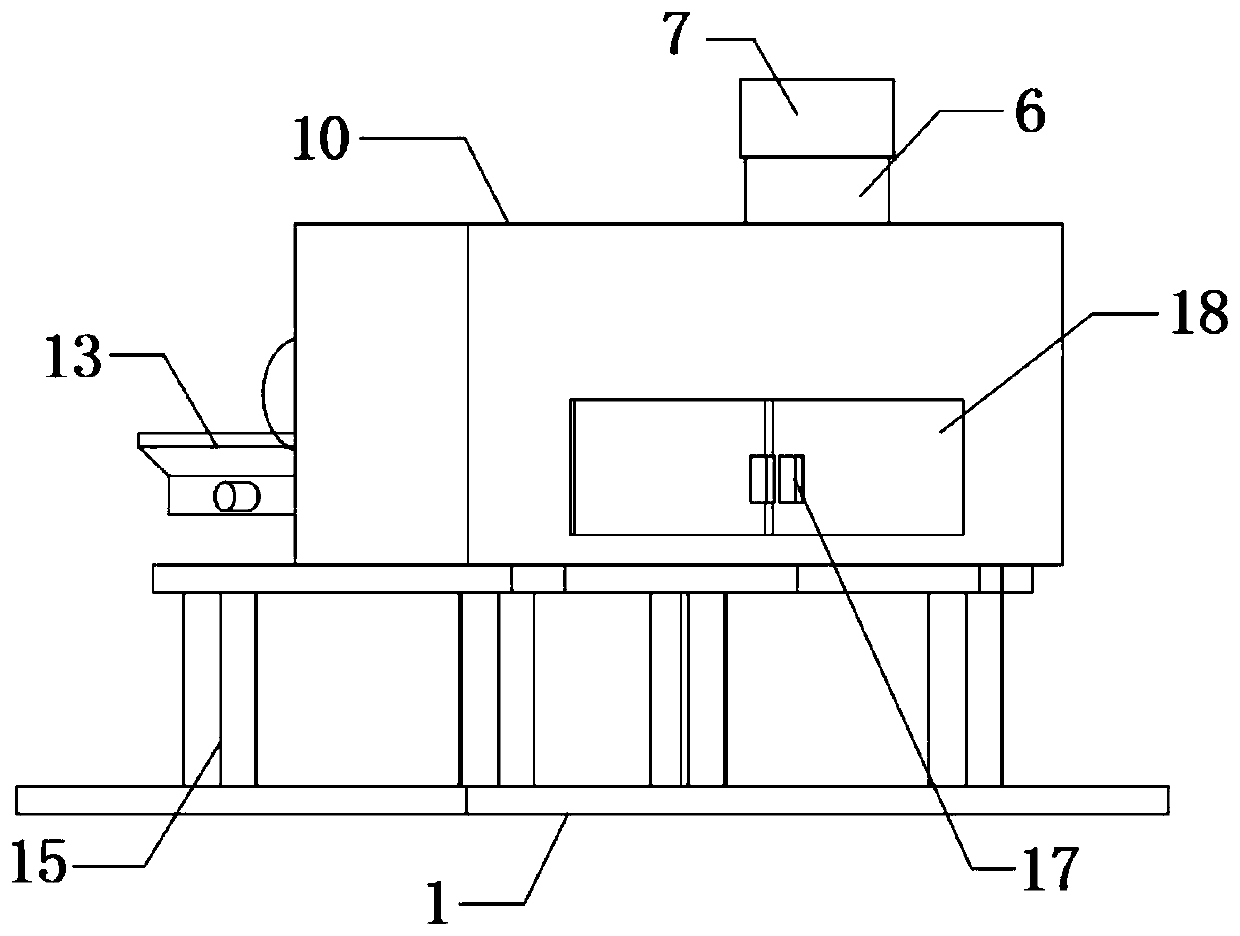

[0028] A plant extract decolorization device, such as Figure 1-2 As shown, including the base plate 1, the top outer wall of the base plate 1 is fixed with four support columns 15 by screws, and the top outer walls of every two support columns 15 are fixed with the same support plate 14 by screws, and the top outer walls of the two support plates 14 The same decolorization box 10 is fixed by screws, and the inner walls of both sides of the decolorization box 10 near the bottom are fixed with a plurality of hydraulic cylinders 2 by screws, and the other end of the plurality of hydraulic cylinders 2 on one side is fixed with the same extruder by screws. The pressing plate 13 and the decolorizing box 10 are provided with a stirring assembly, and the hydraulic cylinder 2 and the extruding plate 13 are provided. After the plant extract is decolorized, the hydraulic cylinder 2 is adjusted to drive the extruding plate 13 to carry out the mixture of the plant extract and the decoloriz...

Embodiment 2

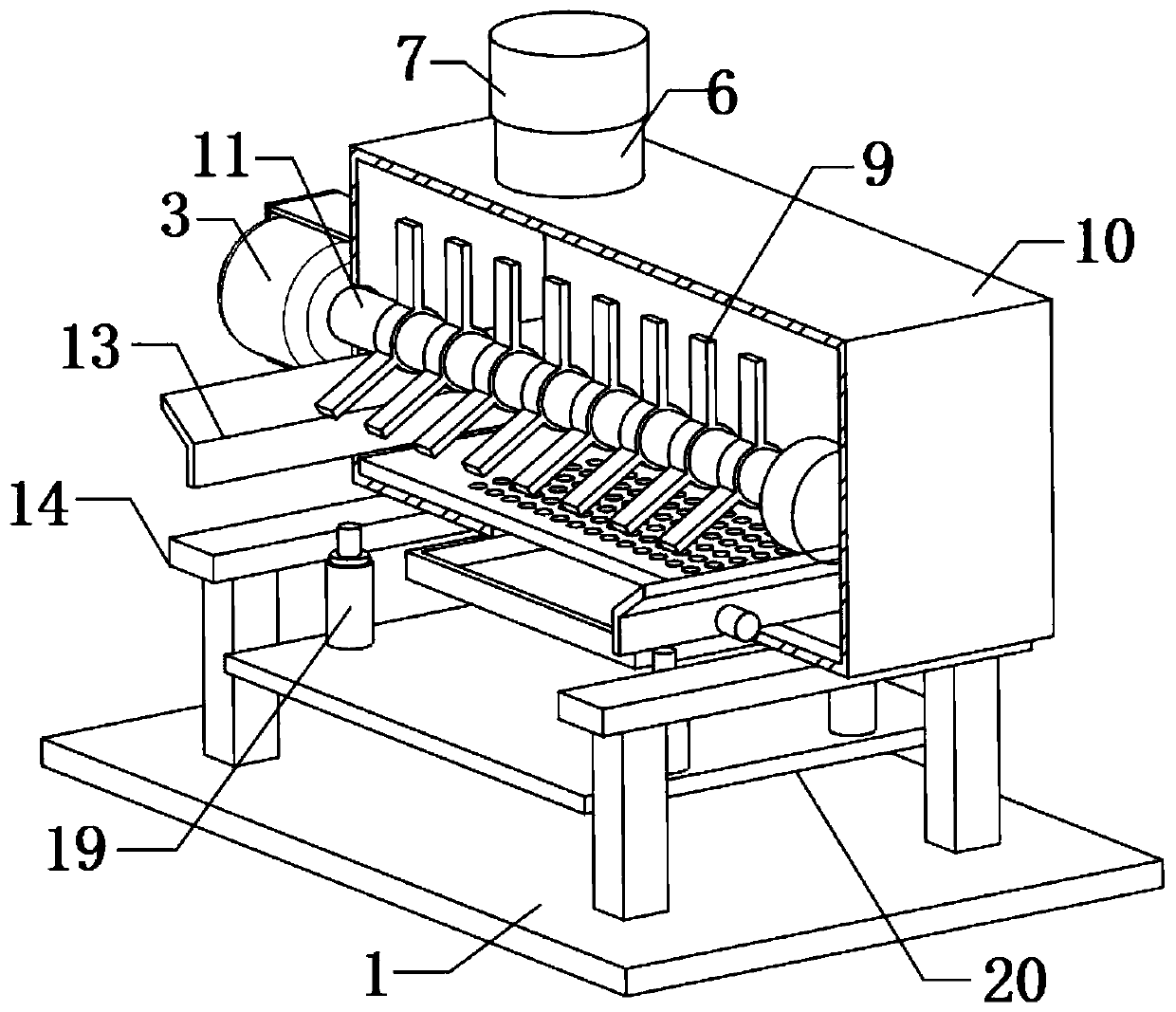

[0037] A plant extract decolorization device, such as Figure 3-4 As shown, in order to solve the problem that the liquid cannot be removed due to the contact between the fixed plate and the bottom inner wall of the decolorization box; this embodiment makes the following improvements on the basis of Embodiment 1: the outer walls of the opposite side of the four support columns 15 are fixed by screws. The same connecting plate 20, and the top outer walls of the four connecting plates 20 are fixed with No. 2 hydraulic cylinders 19 by screws, and the other ends of the four No. 2 hydraulic cylinders 19 are all fixed on the bottom outer walls of the fixed plate 5 by screws. No. two hydraulic cylinders 19 are connected with synchronous hydraulic system, by being provided with No. two hydraulic cylinders 19 and connecting plate 20, one end of No. two hydraulic cylinders 19 is fixed on the bottom of fixed plate 5, when carrying out plant extract and decolorizing agent separation, Adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com