Ethanol dehydration technique adopting molecular sieve catalyst

An ethanol dehydration and molecular sieve technology, applied in the chemical industry, can solve the problems of not meeting the requirements of the processing technology, low ethylene purity, and high reaction temperature, and achieve the effects of avoiding scale formation, low freezing point, and low reaction temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 1% lanthanum modified catalyst and optimized process conditions

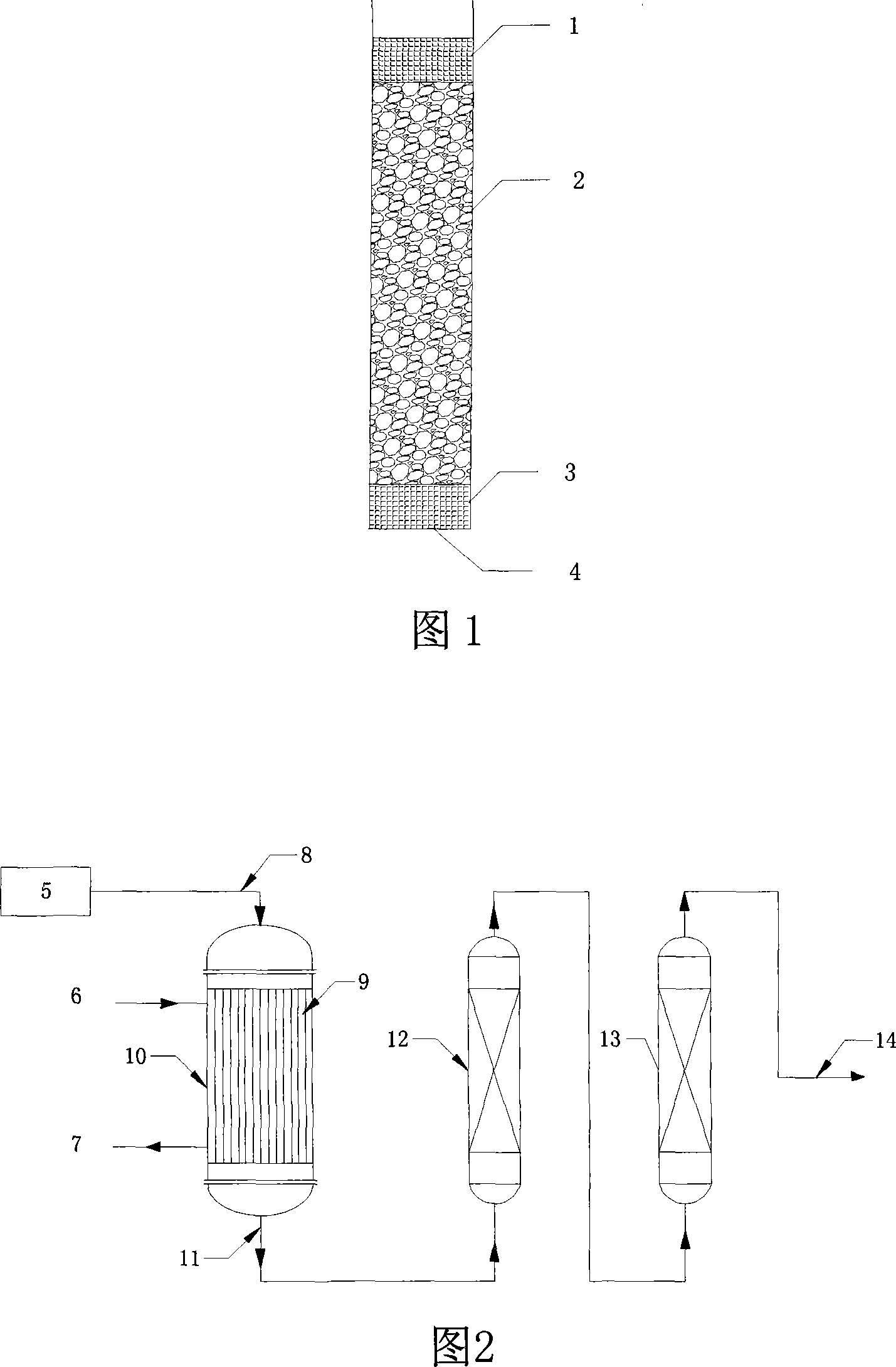

[0043] Catalyst formula: Si-Al ratio 100 molecular sieve raw powder 60g, silica sol 30ml, ammonium dihydrogen phosphate 2.4g, phosphoric acid 24g, sodium carboxymethyl cellulose 1.8g, lanthanum (1%) soaked, potassium hydroxide solution 12ml, molding catalyst.

[0044] HZSM-5 molecular sieve with a Si / Al ratio of 100 is used as the original powder, the binder is sodium carboxymethyl cellulose and water, phosphoric acid is added, and after molding, it is formed in 1%wt La 3+ Soak in the solution, stir at 60°C for 2h, dry at 80°C for 15h, and calcinate at 550°C for 6h in a muffle furnace to obtain a catalyst with a La content of 1 wt%.

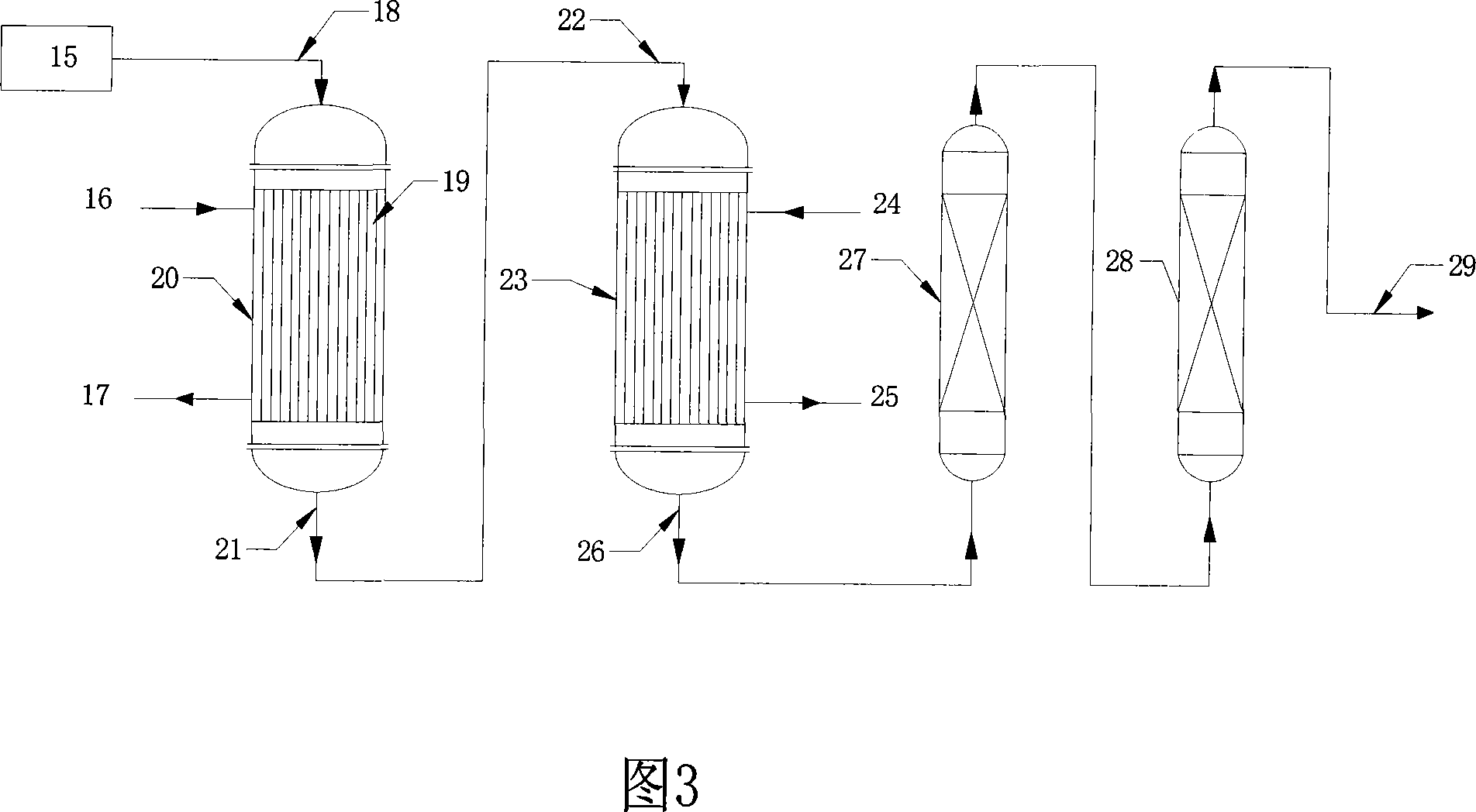

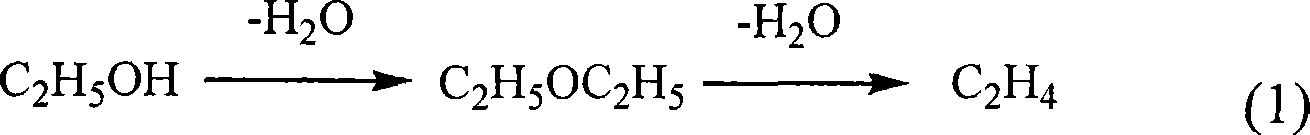

[0045] The shaped catalyst was loaded as shown in Figure 1, and the traditional process Figure 2 and the improved process Figure 3 were respectively inspected, and the results are shown in Table 3.

[0046] By comparison, we found that when one reactor is used fo...

Embodiment 2

[0047] Example 2 3% cobalt modified catalyst and optimized process conditions

[0048] Catalyst formula: 60g of molecular sieve powder with a silicon-aluminum ratio of 100, 30ml of silica sol, 2.4g of ammonium dihydrogen phosphate, 24g of phosphoric acid, 1.8g of sodium carboxymethylcellulose, impregnated with cobalt (3%), impregnated with 12ml of potassium hydroxide solution, and formed catalyst.

[0049] HZSM-5 molecular sieve with a Si / Al ratio of 100 is used as the original powder, the binder is sodium carboxymethyl cellulose and water, phosphoric acid is added, and after molding, the Co 2+ After soaking in the solution, stirring at 60°C for 2h, drying at 80°C for 15h, and calcination at 550°C in a muffle furnace for 6h, a catalyst with a cobalt content of 3wt% was obtained.

[0050] The shaped catalyst was loaded as shown in Figure 1, and the traditional process Figure 2 and the improved process Figure 3 were respectively inspected, and the results are shown in Table 1. ...

Embodiment 3

[0052] Embodiment 3 8% lanthanum modified catalyst and optimized process conditions

[0053] Catalyst formula: 60g of molecular sieve raw powder with a silicon-aluminum ratio of 100, 30ml of silica sol, 2.4g of ammonium dihydrogen phosphate, 24g of phosphoric acid, 1.8g of sodium carboxymethylcellulose, soaked in lanthanum (8%), soaked in 12ml of potassium hydroxide, and formed the catalyst .

[0054] HZSM-5 molecular sieve with a Si / Al ratio of 100 is used as the original powder, the binder is sodium carboxymethylcellulose and water, phosphoric acid is added, and after molding, it is formed in 8%wt La 3+ Soak in the solution, stir at 60°C for 2h, then soak in 0.01mol / L potassium hydroxide solution, stir at 60°C for 2h, dry at 80°C for 15h, and roast at 550°C for 6h in a muffle furnace to obtain a La content of 8wt%. the catalyst.

[0055] The shaped catalyst was loaded as shown in Figure 1, and the traditional process Figure 2 and the improved process Figure 3 were respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com