Application of an ultrasonic wave in the dehydration of biomass tar

A technology of tar dehydration and ultrasonic wave, which is applied in the application of ultrasonic wave in the dehydration of biomass tar, and the field of removing most of the water contained in the biomass tar, can solve the problem of difficult water removal work, long dehydration time and energy consumption. High problems, to achieve the effect of good dehydration effect, high water removal rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

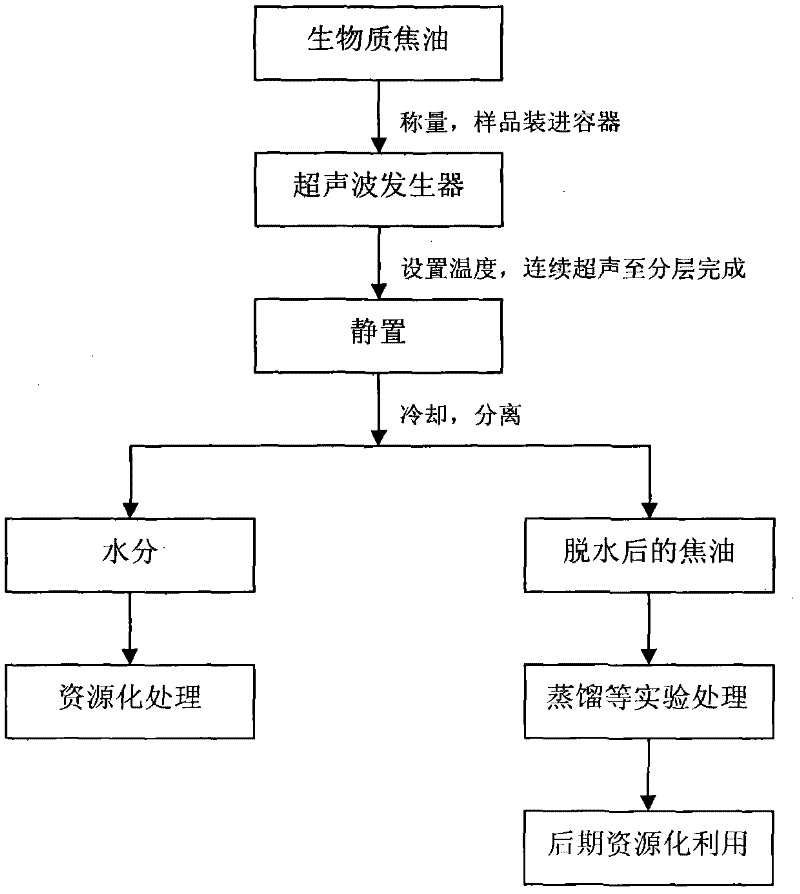

Method used

Image

Examples

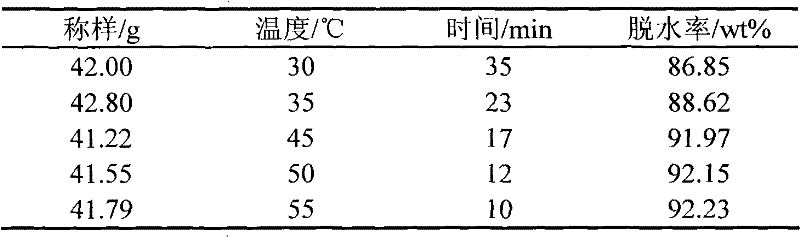

Embodiment 1

[0015] Sampling, weighing 42.00g, 42.80g, 41.22g, 41.55g and 41.79g of biomass pyrolysis tar with a water content of 39% successively, and loading number 1 respectively # ,2 # , 3 # , 4 # , 5 # 100ml graduated cylinder. At a temperature of 30°C, the 1 # Put the measuring cylinder vertically into the ultrasonic generating device, continue ultrasonication for 35 minutes, then take it out and let it stand for separation; raise the temperature to 35°C, put 2 # Put the measuring cylinder vertically into the ultrasonic generating device, continue ultrasonication for 23 minutes, then take it out and let it stand for separation; raise the temperature to 45°C, # Put the measuring cylinder vertically into the ultrasonic generating device, continue ultrasonication for 17 minutes, then take it out and let it stand for separation; raise the temperature to 50°C, # Put the measuring cylinder vertically into the ultrasonic generating device, continue ultrasonication for 12 minutes, then...

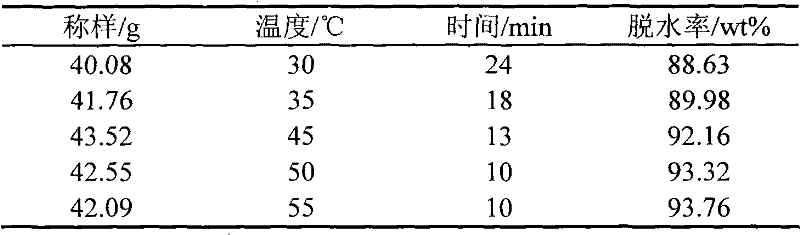

Embodiment 2

[0017] Sampling, weigh 40.08g, 41.76g, 43.52g, 42.55g and 42.09g of biomass carbonized tar with a water content of 24.8% in sequence, and load them into 1 # ,2 # , 3 # , 4 # and 5 # 100ml graduated cylinder. At a temperature of 30°C, the 1 # Put the measuring cylinder vertically into the ultrasonic generating device, continue ultrasonication for 24 minutes, then take it out and let it stand for separation; raise the temperature to 35°C, # Put the measuring cylinder vertically into the ultrasonic generating device, continue ultrasonication for 18 minutes, then take it out and let it stand for separation; raise the temperature to 45°C, and # Put the measuring cylinder vertically into the ultrasonic generating device, continue ultrasonication for 13 minutes, then take it out and let it stand for separation; raise the temperature to 50°C, # Put the cylinder axially vertically into the ultrasonic generator, continue ultrasonication for 10 minutes, then take it out and let it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com