Low-temperature methanol washing method for low-pressure raw gas

A low-temperature methanol washing, raw gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., to achieve the effect of saving investment, expanding the scope of application, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

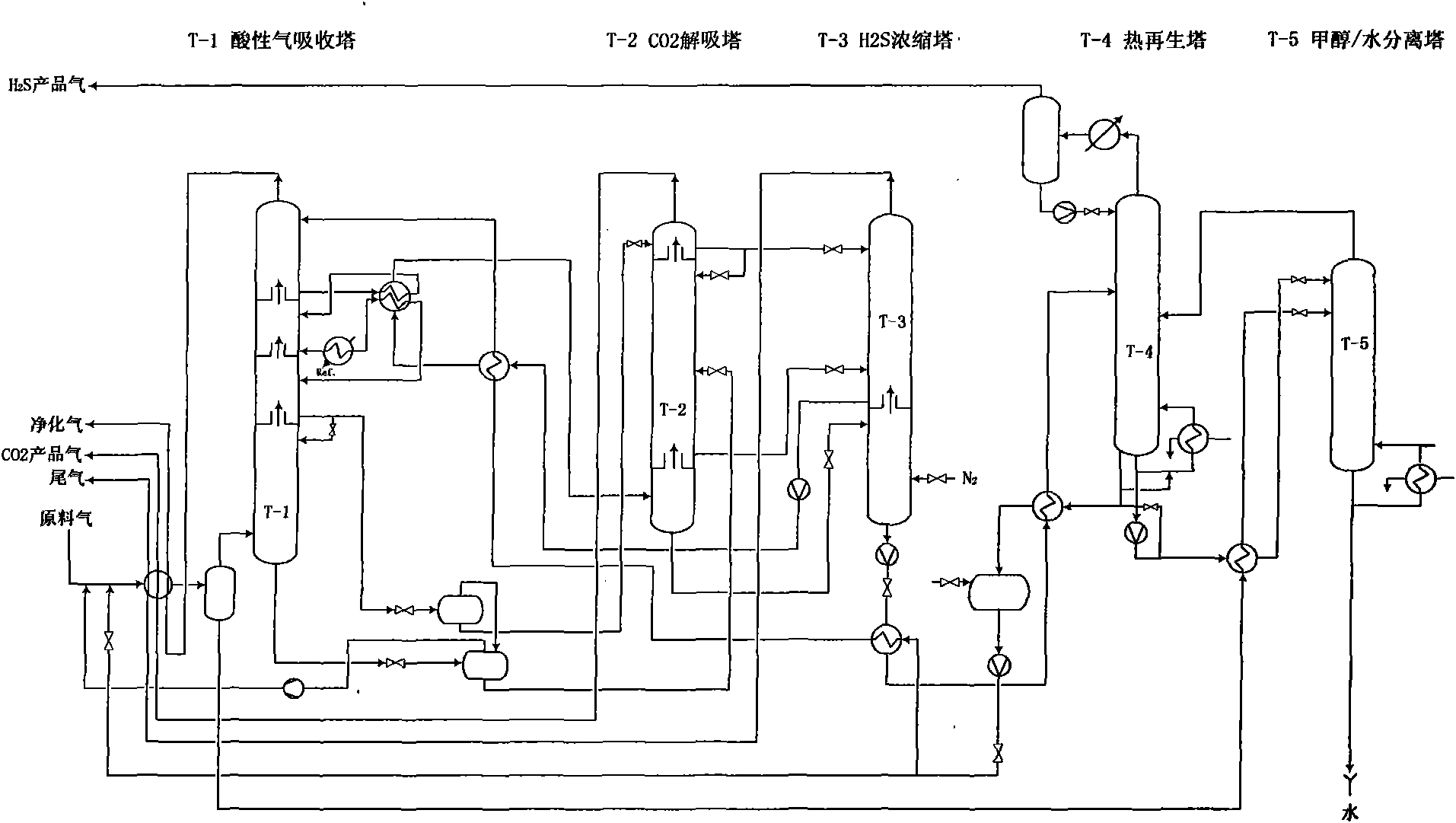

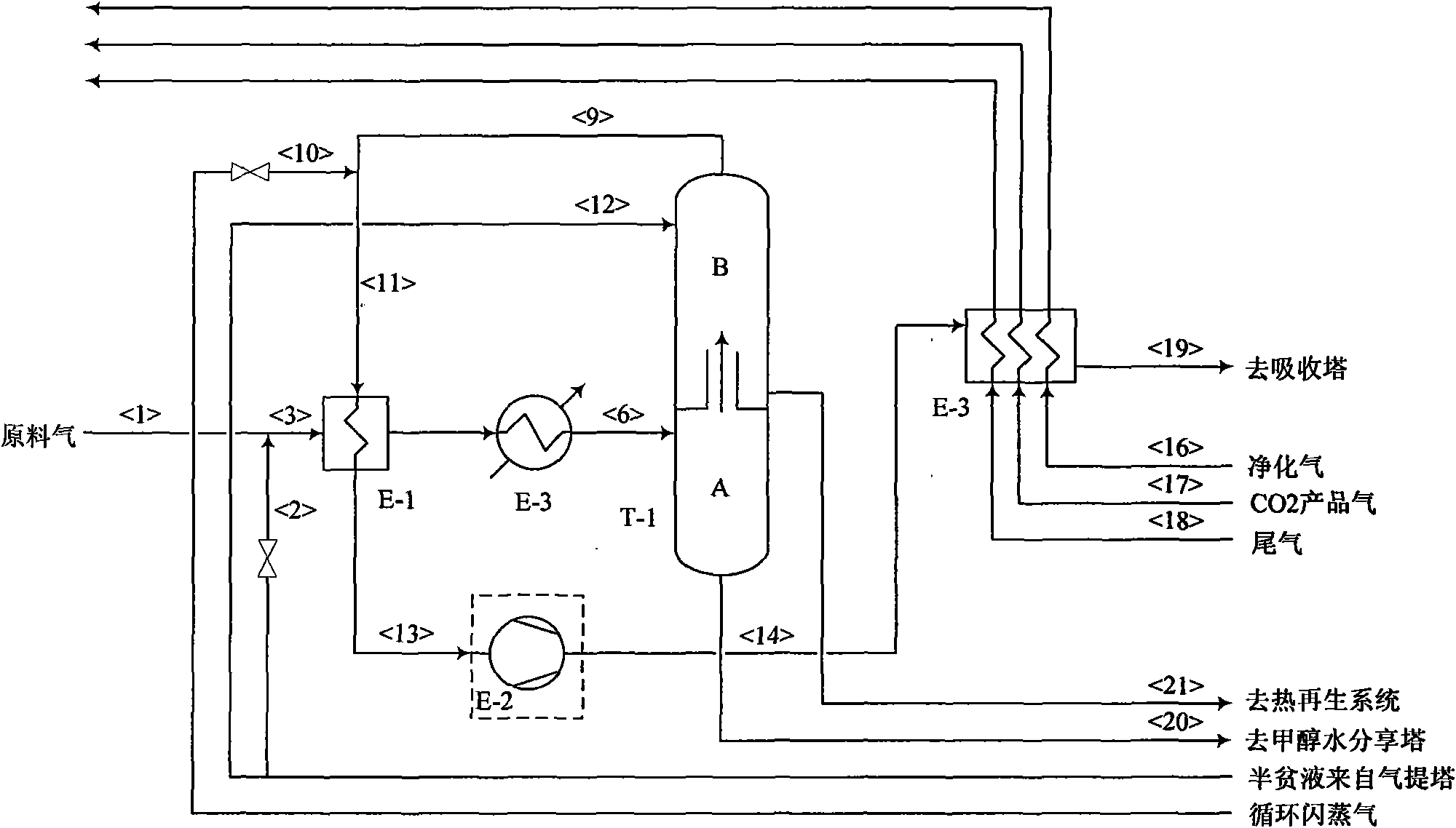

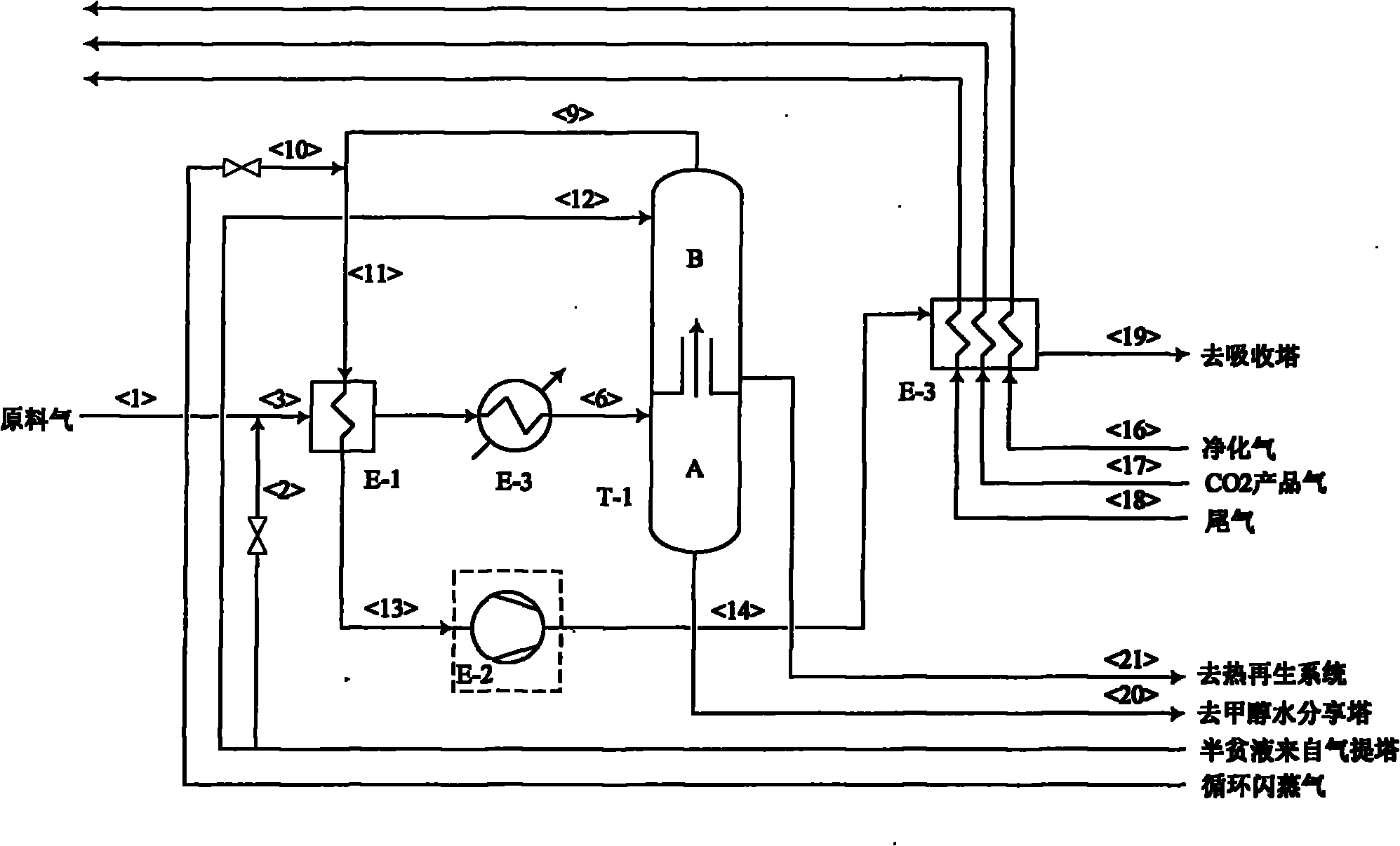

[0030] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0031] The temperature from the transformation process is 40°C, the pressure is 0.70MpaA, and contains H 2 38.95mol%, CO 2 36.79mol%, H 2 S 0.99mol%, H 2 O 1.27mol% low-pressure feed gas is first injected into a small amount of temperature -37.34℃, containing CH3 OH 97.25mol%, CO 2 1.34mol%, H 2 S 0.91mol%, H 2 O0.45mol% semi-lean liquid to prevent the moisture in the raw gas from freezing during the pre-cooling process. The mixed gas is cooled to -20.15°C by the feed gas cooler E-1 and deep cooler E-2, and then enters the separation tank A in the lower part of the pre-washing tower to separate the water and methanol in the feed gas. The separated gas enters the body B of the upper pre-washing tower and is washed with semi-poor solution to remove the moisture in the raw gas. Pre-washed feed gas with temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com