Method and device for synthesizing triethyl citrate by applying vapor permeation dehydration technique

A technology of triethyl citrate and osmotic dehydration is applied in the separation/purification of carboxylate, the preparation of carboxylate, chemical instruments and methods, etc. Avoid secondary evaporation, high product esterification rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

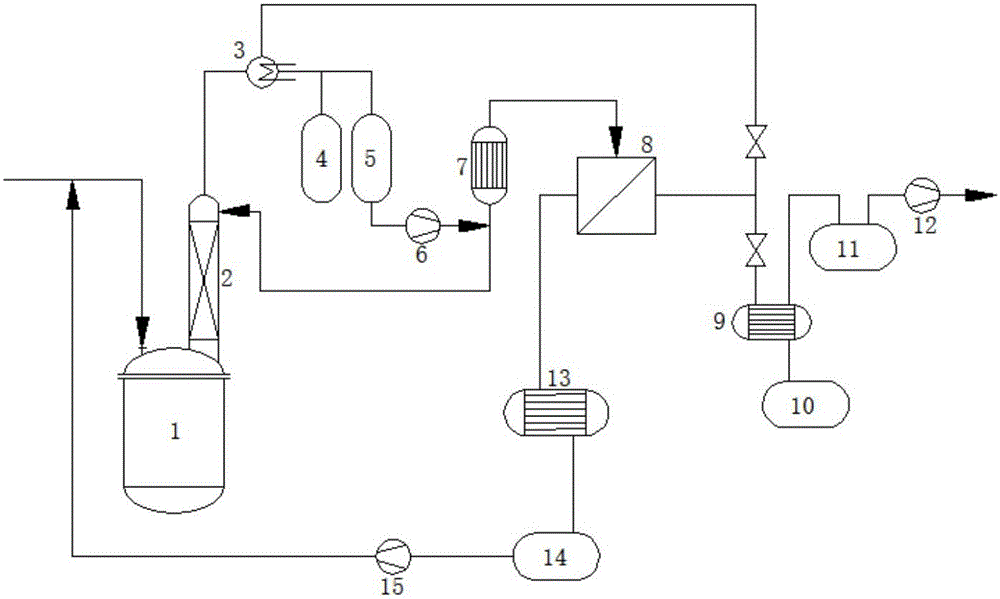

[0036] Steam permeation dehydration technology is used for the method for synthesizing triethyl citrate, the device that adopts is as figure 1 As shown, the operation process includes the following steps:

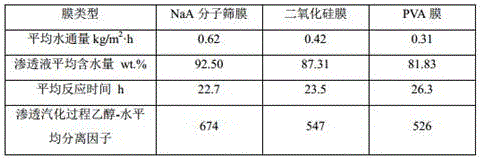

[0037] Put 5 kg of citric acid, 6.17kg of absolute ethanol, and 45g of p-toluenesulfonic acid into the reactor 1 for heating and reaction, and carry out the esterification reaction under the catalysis of the catalyst. The temperature in the reactor is 115°C, and the rising steam in the reactor Heat and mass transfer with the descending reflux liquid in the rectification column 2, the temperature at the top of the rectification column is controlled at about 78°C, and the feed liquid (mainly ethanol) evaporated from the top of the column is condensed by the top condenser 3 and then flows into In the ethanol receiving tank 5, a part of the overhead distillate is used as the reflux liquid with a reflux ratio of 1, and the other part is used as the raw material liquid in the ste...

Embodiment 2

[0043] Steam permeation dehydration technology is used for the method for synthesizing triethyl citrate, the device that adopts is as figure 1 As shown, the operation process includes the following steps:

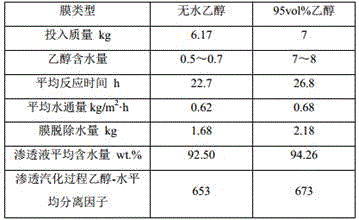

[0044] Put 5 kg of citric acid, a certain amount of 95vol% ethanol or absolute ethanol, and 45g of p-toluenesulfonic acid into the reaction kettle 1 for heating and reaction, and carry out the esterification reaction under the catalytic action of the catalyst. The temperature in the reaction kettle is 120°C. The ascending steam and descending reflux liquid in the still conduct heat and mass transfer in the rectification column 2, the temperature of the top of the rectification column is controlled at about 78°C, and the liquid (mainly ethanol) evaporated from the top of the tower is condensed at the top of the tower After being condensed by the device 3, it flows into the ethanol receiving tank 5, a part of the overhead distillate is used as the reflux liquid, and the reflu...

Embodiment 3

[0050] Steam permeation dehydration technology is used for the method for synthesizing triethyl citrate, the device that adopts is as figure 1 As shown, the operation process includes the following steps:

[0051] Put 5 kg of citric acid, 6.17 kg of absolute ethanol, and 45 g of catalysts (cationic catalytic resin, concentrated sulfuric acid, p-toluenesulfonic acid) into reactor 1 for heating and reaction, and carry out esterification reaction under the catalysis of the catalyst. The temperature in the reactor is The rising steam and the descending reflux liquid in the reactor conduct heat and mass transfer in the rectification column 2. The temperature at the top of the rectification column is controlled at about 78°C, and the liquid (mainly ethanol) evaporated from the top of the ) flows into the ethanol receiving tank 5 after being condensed by the tower top condenser 3, a part of the tower top distillate is used as the reflux liquid, and the reflux ratio is 1.5, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com