High-voltage pulsed electric field-cyclone centrifugal field combined lubricating oil demulsification and dehydration device

A technology of high-voltage pulse electric field and high-voltage pulse power supply, which is applied in the direction of electric/magnetic dehydration/demulsification, lubricating composition, mechanical dehydration/demulsification, etc., which can solve the problems of poor treatment effect, high energy consumption, and long time consumption, etc. problem, to achieve the effect of short time-consuming, low energy consumption and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

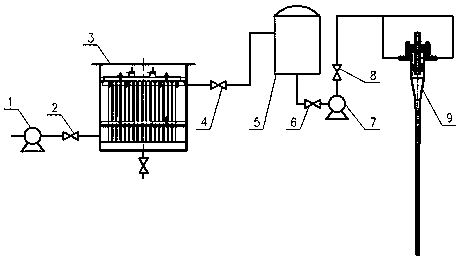

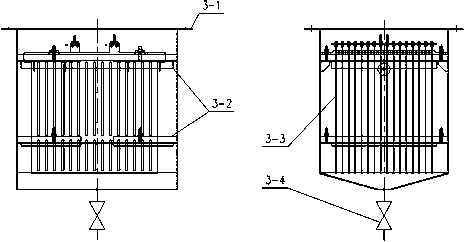

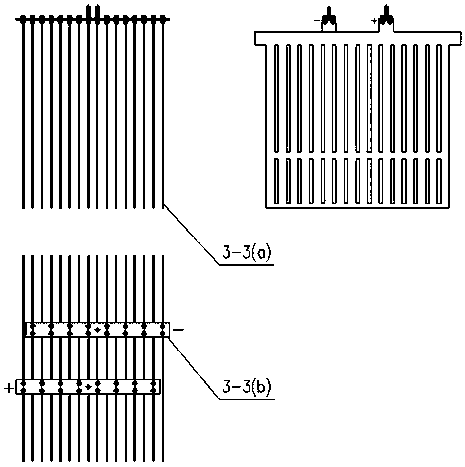

[0044] 1) A high-voltage pulse electric field-swirl centrifugal field combined lubricating oil demulsification and dehydration device, including an oil inlet pump 1 (1), an oil delivery valve 1 (2), a high-voltage pulse electric field demulsification and dehydration device (3), and an oil delivery valve 2(4), buffer oil storage tank (5), oil delivery valve 3(6), oil inlet pump 2(7), oil delivery valve 3(8), cyclone centrifugal demulsification and dehydration device (9), characterized in that : The oil inlet pump 1 (1) is connected to the lubricating oil that needs to be demulsified and dehydrated through the oil pipeline, and then through the oil pipeline and the oil delivery valve 1 (2), the high-voltage pulse electric field demulsification and dehydration device (3), and the oil delivery valve 2 (4), buffer oil storage tank (5), oil delivery valve 3 (6), oil inlet pump 2 (7), oil delivery valve 3 (8) and cyclone centrifugal demulsification dehydration device (9) link to each ...

no. 2 example

[0055] 1) A high-voltage pulse electric field-swirl centrifugal field combined lubricating oil demulsification and dehydration device, including an oil inlet pump 1 (1), an oil delivery valve 1 (2), a high-voltage pulse electric field demulsification and dehydration device (3), and an oil delivery valve 2(4), buffer oil storage tank (5), oil delivery valve 3(6), oil inlet pump 2(7), oil delivery valve 3(8), cyclone centrifugal demulsification and dehydration device (9), characterized in that : The oil inlet pump 1 (1) is connected to the lubricating oil that needs to be demulsified and dehydrated through the oil pipeline, and then through the oil pipeline and the oil delivery valve 1 (2), the high-voltage pulse electric field demulsification and dehydration device (3), and the oil delivery valve 2 (4), buffer oil storage tank (5), oil delivery valve 3 (6), oil inlet pump 2 (7), oil delivery valve 3 (8) and cyclone centrifugal demulsification dehydration device (9) link to each ...

no. 3 example

[0066] 1) A high-voltage pulse electric field-swirl centrifugal field combined lubricating oil demulsification and dehydration device, including an oil inlet pump 1 (1), an oil delivery valve 1 (2), a high-voltage pulse electric field demulsification and dehydration device (3), and an oil delivery valve 2(4), buffer oil storage tank (5), oil delivery valve 3(6), oil inlet pump 2(7), oil delivery valve 3(8), cyclone centrifugal demulsification and dehydration device (9), characterized in that : The oil inlet pump 1 (1) is connected to the lubricating oil that needs to be demulsified and dehydrated through the oil pipeline, and then through the oil pipeline and the oil delivery valve 1 (2), the high-voltage pulse electric field demulsification and dehydration device (3), and the oil delivery valve 2 (4), buffer oil storage tank (5), oil delivery valve 3 (6), oil inlet pump 2 (7), oil delivery valve 3 (8) and cyclone centrifugal demulsification dehydration device (9) link to each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com