Low-temperature demulsifier suitable for naphthenic-intermediate base crude oil emulsion and its preparation and use

A technology of intermediate base crude oil and emulsion, which is applied in the direction of dehydration/emulsion breaking by chemical methods, can solve the problems of not having broad spectrum, weak applicability, and poor effect, so as to improve the efficiency of demulsification and dehydration, reduce the High oil-water interfacial tension and high demulsification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

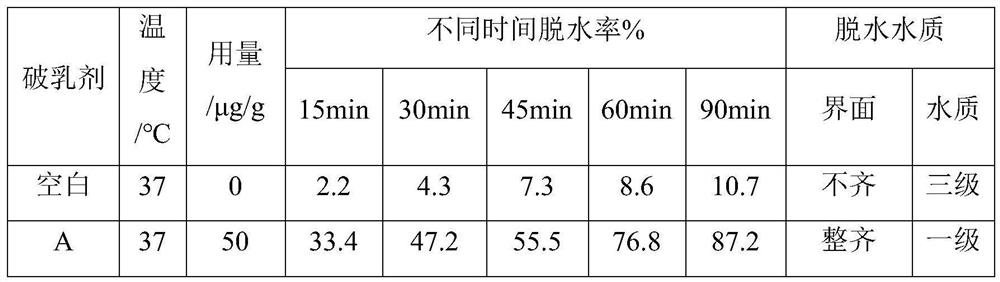

Examples

Embodiment 1

[0026] In the stirred reactor, add the N-methylimidazole that quality is respectively 0.5kg, the n-heptane bromide of 0.3kg and the normal heptane of 714ml, the n-heptane of described N-methylimidazole, n-hexane bromide and, The mass ratio is 1:0.6:1, and nitrogen is used to replace the air in the stirred reactor for 3 times, so that the stirred reactor is in a nitrogen atmosphere. The reactor was heated to 90°C under stirring, and the stirring was stopped after 2 hours of reaction.

[0027] After the reacted crude product was cooled to 25°C, the crude product and acetone were mixed and shaken according to the volume ratio of 1:5. In this example, the amount of acetone added was 3570ml, and it was rotary evaporated at 40°C for 8 minutes, that is 1-Hexyl-3-methylimidazole bromide ([HMIM]Br) was obtained as a solid.

[0028] Add the above-mentioned [HMIM]Br and 0.32kg of ammonium fluoroborate NH with a quality of 0.64kg in the stirred reactor 4 BF 4 And 823ml of methanol, the...

Embodiment 2

[0031] The ionic liquid [HMIM] BF used in this embodiment 4 The preparation process is described in Example 1.

[0032] In the stirred reactor, add the [HMIM] BF of 0.1kg p-phenoxy dilauryl alcohol (HBA) and 0.3kg 4 , replaced with nitrogen for 3 times, heated the reactor to 130°C under stirring, quickly added 0.1kg of ethylene oxide, stopped stirring after 1.0h of reaction, cooled to room temperature and rotary steamed at 25°C for 2 minutes to obtain p-phenoxy Ionic liquid solution of dilauryl ether (HBA(EO) n -IL). Get 0.3kg of the ionic liquid solution of p-phenoxy dilauryl ether, then add 0.03kg of decanyl alcohol polyoxyethylene ether, 0.04kg of octylphenol polyoxyethylene ether and 0.03kg of allyl polyoxyethylene ether to mix, Stir evenly to obtain ionic liquid demulsifier A.

[0033] In the present embodiment, the amount of the ionic liquid solution of phenoxy dilauryl ether is 75 parts by weight, the amount of decyl alcohol polyoxyethylene ether is 7.5 parts by wei...

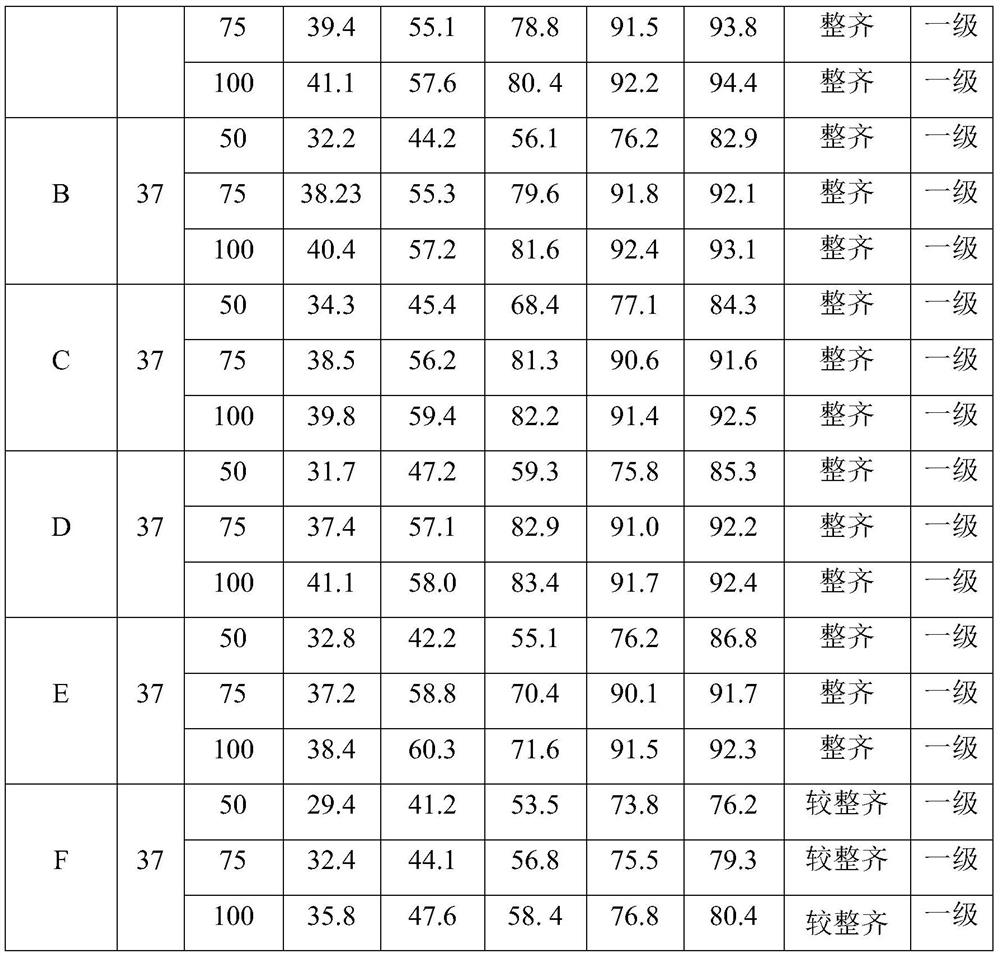

Embodiment 3

[0035] The ionic liquid [HMIM] BF used in this embodiment 4 The preparation process is described in Example 1.

[0036] In the stirred reactor, add the [HMIM] BF of 0.08kg p-phenoxy dilauryl alcohol (HBA) and 0.3kg 4 , replaced with nitrogen for 3 times, heated the reactor to 130°C under stirring, quickly added 0.08kg of ethylene oxide, stopped stirring after 1.5h of reaction, cooled to room temperature and rotary steamed at 25°C for 2 minutes to obtain p-phenoxy Ionic liquid solution of dilauryl ether (HBA(EO) n -IL). Get 0.15kg of ionic liquid solution of p-phenoxy dilauryl ether, add 0.02kg of decanyl alcohol polyoxyethylene ether, 0.015kg of octylphenol polyoxyethylene ether and 0.015kg of allyl polyoxyethylene ether to mix, Stir evenly to obtain ionic liquid demulsifier B.

[0037] In the present embodiment, the amount of the ionic liquid solution of phenoxy dilauryl ether is 75 parts by weight, the amount of decanyl alcohol polyoxyethylene ether is 10 parts by weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com