A demulsifier suitable for high-sulfur and high-salt production fluid crude oil emulsion

A technology for produced liquid and emulsion, applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of high energy consumption, high consumption, unstable crude oil water content index, etc., to reduce energy consumption, reduce the dosage of chemicals, improve the The effect of demulsification and dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

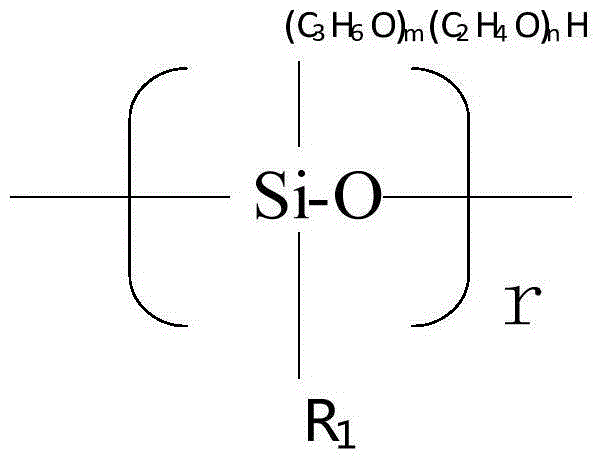

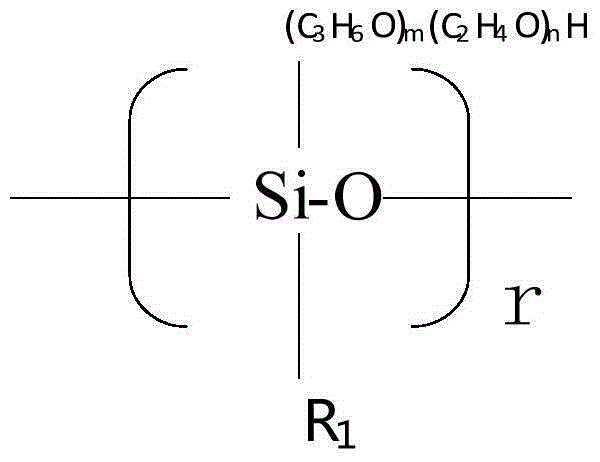

[0025] Put hydrogen-containing polyoxysilane and KOH catalyst into the synthesis kettle, repeatedly fill with nitrogen and pump negative pressure, until the oxygen in the kettle is completely converted, slowly raise the temperature to 120 ° C ~ 150 ° C, and drop PO (propylene oxide) in proportion , keep the pressure at 0.2-0.5MPa, and the temperature does not exceed 150°C. After the dropwise addition was completed, the constant temperature was maintained for 30 min. Then add EO (ethylene oxide) dropwise in proportion. Similarly, keep the pressure at 0.2-0.5 MPa, and the temperature does not exceed 150°C. Control PO:EO=1:2.5~3. After the dropwise addition was completed, the constant temperature was maintained for 40 min. The temperature is lowered to below 30°C, and poly-12 alkyl α-olefin and ethylene glycol are sequentially added to obtain a finished demulsifier.

[0026] Among them, the synthesis of poly-12 alkyl α-olefin is an existing process, which will not be described...

Embodiment 2

[0029] Put hydrogen-containing polyoxysilane and KOH catalyst into the synthesis kettle, repeatedly fill with nitrogen and pump negative pressure, until the oxygen in the kettle is completely converted, slowly raise the temperature to 120 ° C ~ 150 ° C, and drop PO (propylene oxide) in proportion , keep the pressure at 0.2-0.5MPa, and the temperature does not exceed 150°C. After the dropwise addition was completed, the constant temperature was maintained for 30 min. Then add EO (ethylene oxide) dropwise in proportion. Similarly, keep the pressure at 0.2-0.5 MPa, and the temperature does not exceed 150°C. Control PO:EO=1:1.5~2. After the dropwise addition was completed, the constant temperature was maintained for 40 min. The temperature is lowered to below 30°C, and poly-18 alkyl α-olefin and glycerol are sequentially added to obtain a finished demulsifier.

[0030] Among them, the synthesis of poly-18 alkyl α-olefin is an existing process, which will not be described in det...

Embodiment 3

[0033] Put hydrogen-containing polyoxysilane and KOH catalyst into the synthesis kettle, repeatedly fill with nitrogen and pump negative pressure, until the oxygen in the kettle is completely converted, slowly raise the temperature to 120 ° C ~ 150 ° C, and drop PO (propylene oxide) in proportion , keep the pressure at 0.2-0.5MPa, and the temperature does not exceed 150°C. After the dropwise addition was completed, the constant temperature was maintained for 30 min. Then add EO (ethylene oxide) dropwise in proportion. Similarly, keep the pressure at 0.2-0.5 MPa, and the temperature does not exceed 150°C. Control PO:EO=1:3~3.5. After the dropwise addition was completed, the constant temperature was maintained for 40 min. The temperature is lowered to below 30°C, and the mixed polyalkylene α-olefin and propylene glycol are sequentially added to obtain a finished demulsifier.

[0034] Among them, the synthesis of polyalkyl α-olefins is an existing process, which will not be de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com