Combined sludge deep dehydration system and deep dehydration technique

A deep dehydration and combined technology, which is applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of unclean filter cloth cleaning, high solid content of separation liquid, The problem of high moisture content in mud cake can achieve the effect of simple management, improved dehydration performance and large processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

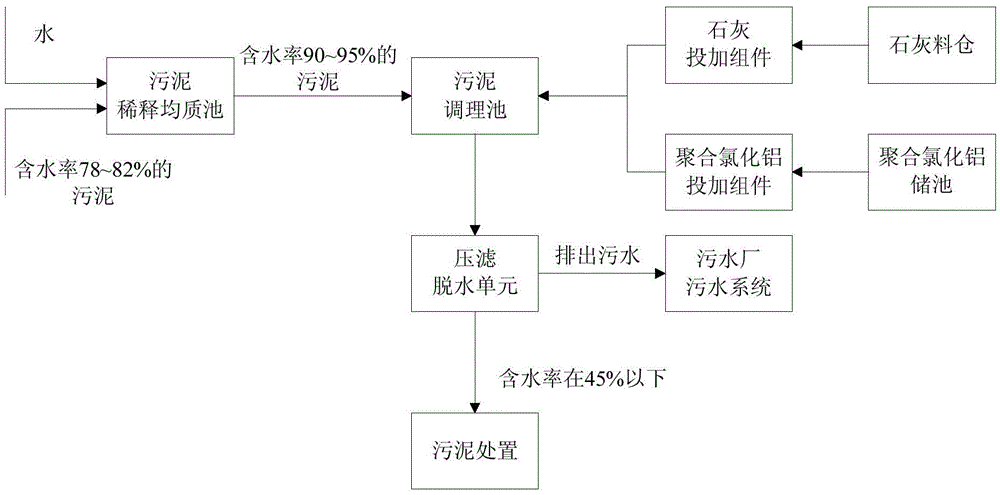

[0061] The resource utilization project of sludge treatment and disposal in a certain city has a treatment scale of 200t / d (moisture content 78-82%), such as figure 1 and Figure 4 As shown, a combined sludge advanced dewatering system includes a sludge feeding unit, a sludge conditioning modification unit and a filter press dewatering unit. The sludge feeding unit includes a sludge dilution homogeneous tank and a sludge mixing tank. A conveying component, the sludge dilution and homogenization tank is connected to the sludge conditioning and modification unit through a sludge mixing and conveying component, and the sludge conditioning and modification unit is connected to the filter press dehydration unit. The inlet of the sludge dilution and homogenization tank is provided with a 45-60° slope 1, a grid 2 and a hydraulic tank cover 3, and the sludge dilution and homogenization tank is buried, and the height of the tank top above the ground is h It is 0.3-0.5m.

[0062] The ...

Embodiment 2

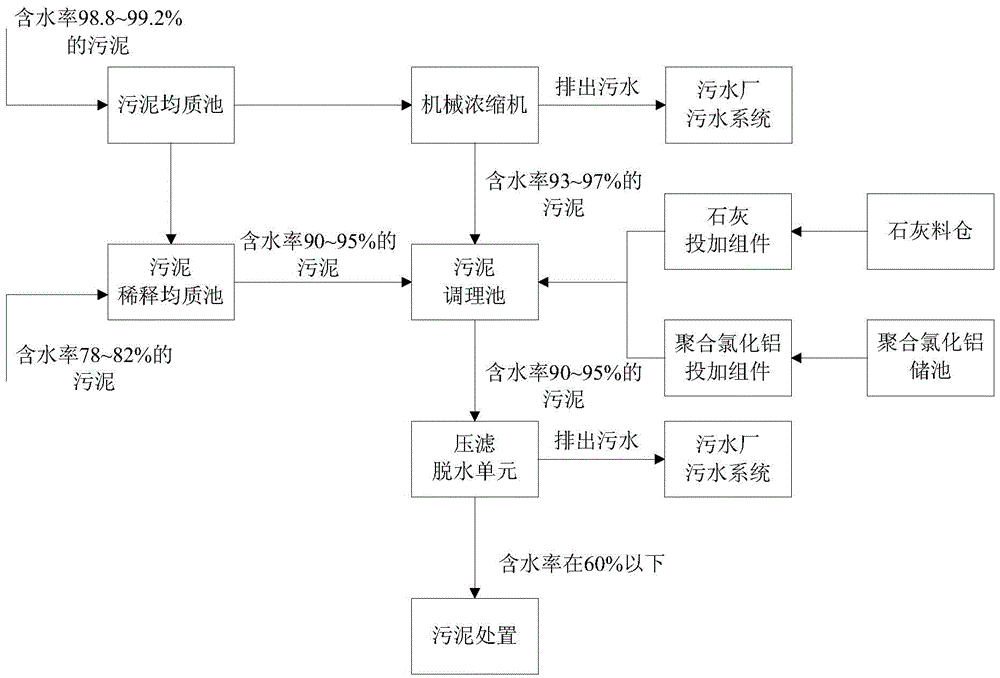

[0072] The sludge advanced treatment center project in a certain city has a treatment scale of 500t / d (200t / d (moisture content 78-82%)+300t / d (moisture content 98.8-99.2%)), such as figure 2 and Figure 4 As shown, a combined sludge advanced dewatering system includes a sludge feeding unit, a sludge conditioning modification unit and a filter press dewatering unit. The sludge feeding unit includes a sludge dilution homogeneous tank, a sludge mixing conveying component, sludge homogenizing tank, lift pump, mechanical thickener and dosing component, the sludge dilution homogenizing tank is connected with the sludge conditioning and modifying unit through the sludge mixing and conveying component, and the sludge is The mass pool is connected to the mechanical thickener through a lifting pump, the sludge homogenizer is also connected to the sludge dilution homogeneous pool, the mechanical thickener is connected to the sludge conditioning modification unit, and the The dosing co...

Embodiment 3

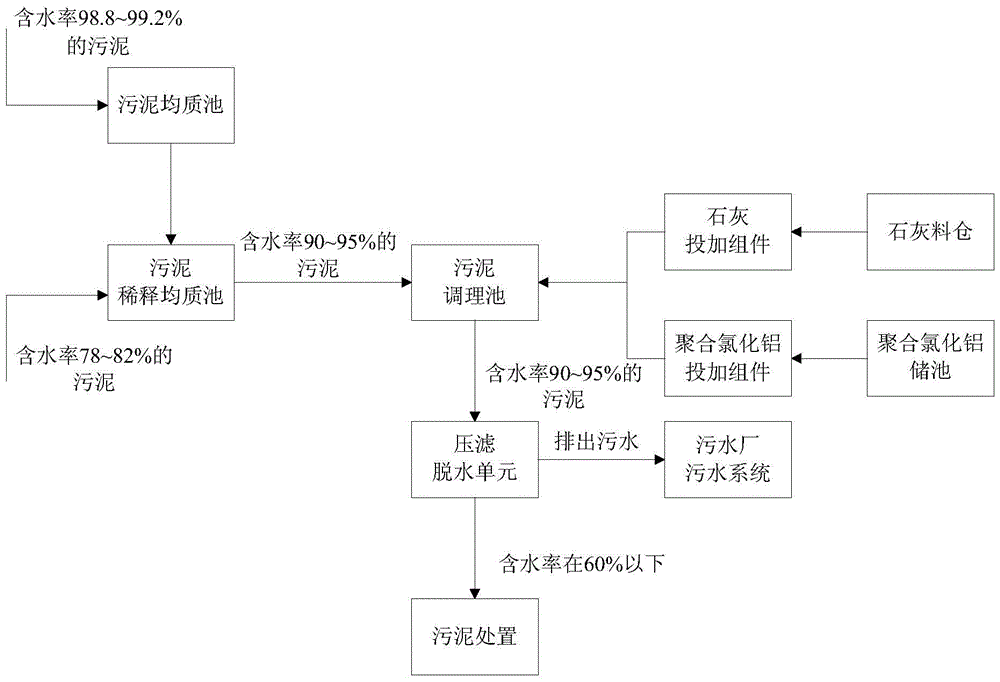

[0083] The sludge deep dehydration project in a certain city has a processing scale of 600t / d (300t / d (moisture content 78-82%)+300t / d (moisture content 98.8-99.2%)), such as image 3 with Figure 4 As shown, a combined sludge advanced dewatering system includes a sludge feeding unit, a sludge conditioning modification unit and a filter press dewatering unit. The sludge feeding unit includes a sludge dilution homogeneous tank, a sludge mixing conveying component, sludge homogenizing tank, lift pump, mechanical thickener and dosing component, the sludge dilution homogenizing tank is connected with the sludge conditioning and modifying unit through the sludge mixing and conveying component, and the sludge is The mass pool is connected to the mechanical thickener through a lifting pump, the sludge homogenizer is also connected to the sludge dilution homogeneous pool, the mechanical thickener is connected to the sludge conditioning modification unit, and the The dosing component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com