Aged sump oil treatment process

A technology for processing and aging oil, applied in the direction of multi-stage series refining process treatment, etc., can solve the problems of unstable operation of electric desalination, poor technical adaptability, increased power consumption, etc., to eradicate safety and environmental hidden dangers, and easy to operate. , the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

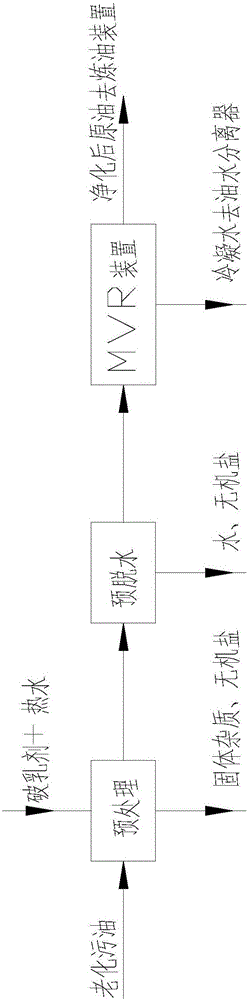

[0021] Such as figure 1 Shown, a kind of aging waste oil treatment process, this treatment process step comprises the following steps:

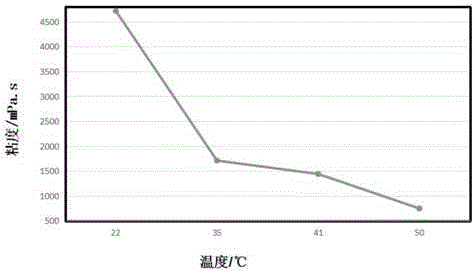

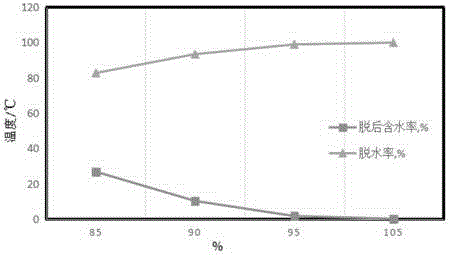

[0022] 1) Pretreatment of aged slop oil: Use the oil transfer pump to transport the aged slop oil in the oil collection tank to the pretreatment unit, heat the aged slop oil to 60~90°C with steam in the pretreatment unit, add the same temperature The amount of hot water and demulsifier, the amount of hot water is 1~3 times that of aging oil, and the amount of demulsifier is 10~50ppm. And use a mechanical stirrer to fully stir and mix; the fully mixed oil-water mixture is ultrasonically treated, and the solid impurities, heavy metal ions, polymer compounds and The free water is separated from the aged oil, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com