Operation control method, system and air compressor system

An air compressor and operation control technology, applied in the field of rail transit, can solve the problems of short single operation time and emulsification of lubricating oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

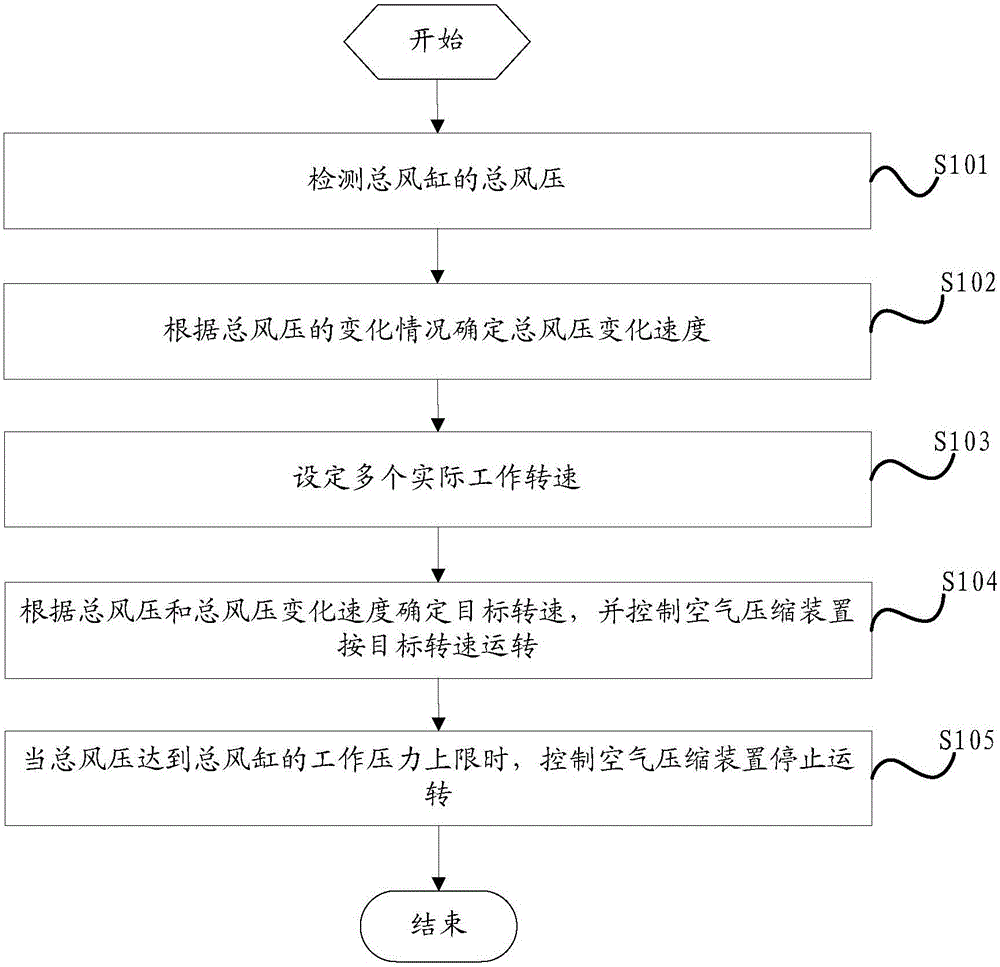

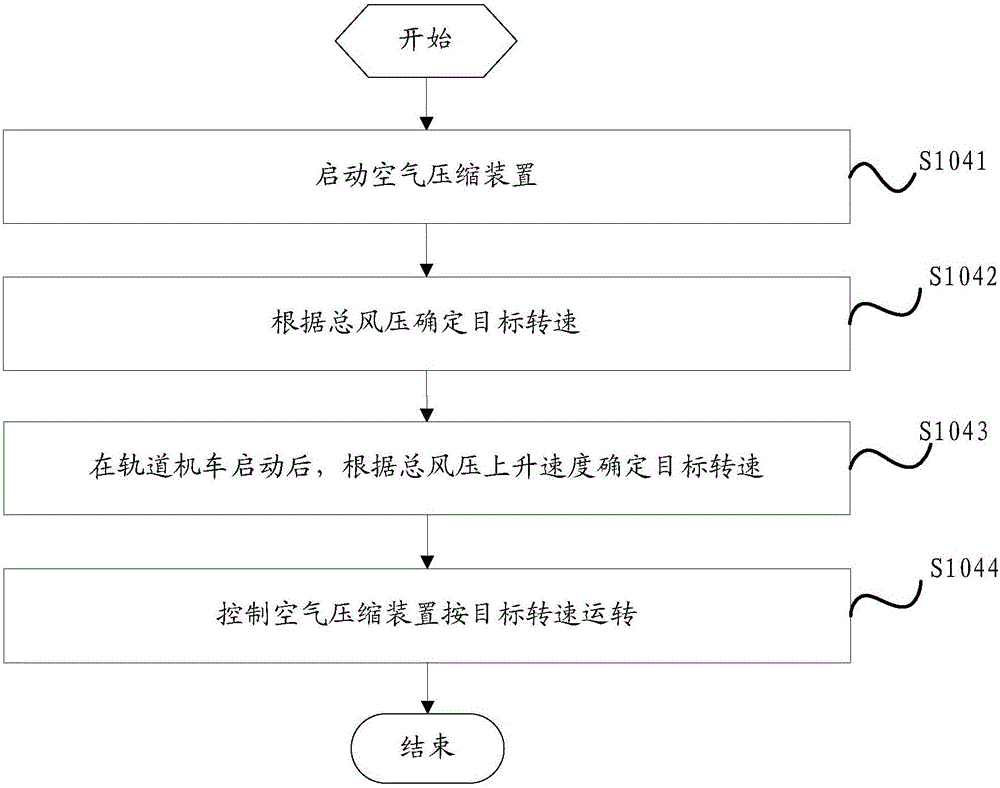

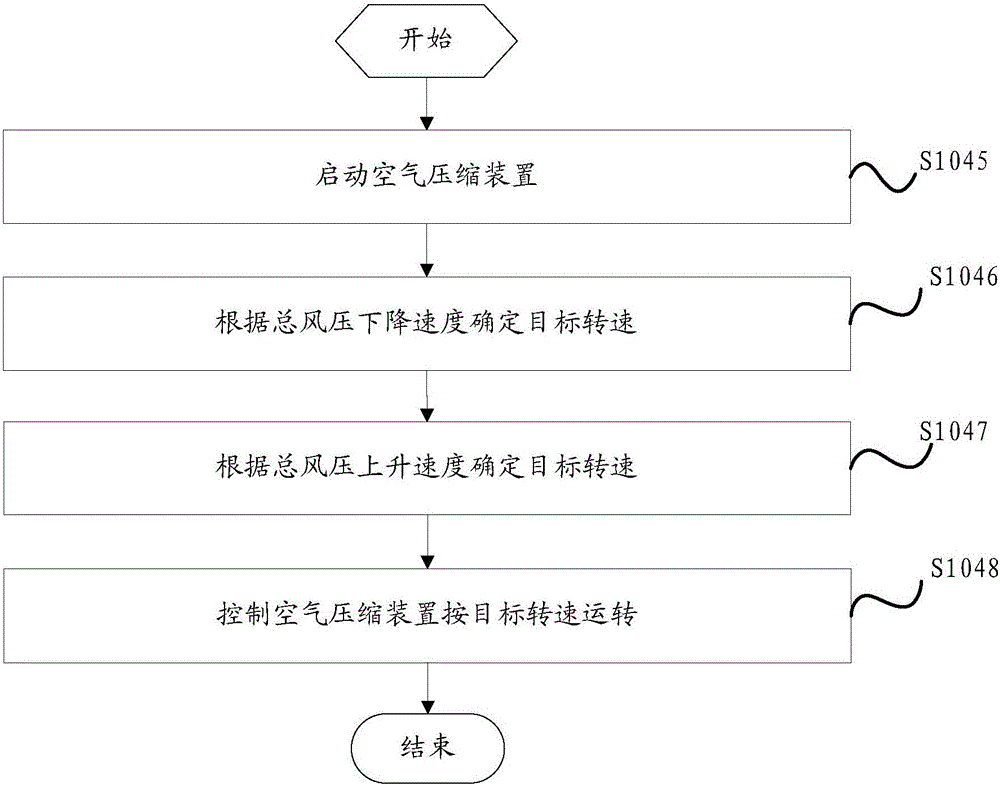

[0062] figure 1 It is a flow chart of steps of an operation control method provided in the embodiment of the present application.

[0063] Such as figure 1 As shown, the operation control method provided in this embodiment is applicable to the air compressor system of a rail vehicle, and the air compressor system includes an air compression device and a main air cylinder. The air compression device generally includes two compressors, namely the first compressor and the second compressor. The air inlet of the main air cylinder is connected with the air outlet of the two compressors for storing compressed air. The operation control method Specifically include the following steps:

[0064] S101: Detect the total air pressure of the main air cylinder.

[0065] The pressure of the main air cylinder is detected by means of a pressure detection device arranged on the main air pipe of the main air cylinder, and the total wind pressure reflecting the pressure of the total air cylind...

Embodiment 2

[0102] Figure 4 It is a structural block diagram of an operation control system provided by another embodiment of the present application.

[0103] Such as Figure 4 As shown, the operation control system provided in this embodiment is used to control the air compressor system of the rail vehicle, and the air compressor system includes an air compression device and a main air cylinder. The air compression device generally includes two compressors, namely the first compressor and the second compressor. The air inlet of the main air cylinder is connected with the air outlet of the two compressors to store compressed air. The operation control system It includes a total wind pressure detection module 10 , a total wind pressure change calculation module 20 , a working speed setting module 30 and an operation control module 40 .

[0104] The total wind pressure detection module 10 is used to detect the total wind pressure of the total wind cylinder.

[0105] Specifically, the p...

Embodiment 3

[0135] This embodiment provides an air compressor system, and the air compressor system is provided with the operation control system provided by the above embodiments. It can avoid emulsification of lubricating oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com