External tunneling machine cutting part cutting head for sealing water

A cutting head and cutting part technology, applied in the field of cutting heads, can solve problems such as water leakage and oil cavity, and achieve the effects of reasonable structure, simple structure and solving the problem of emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

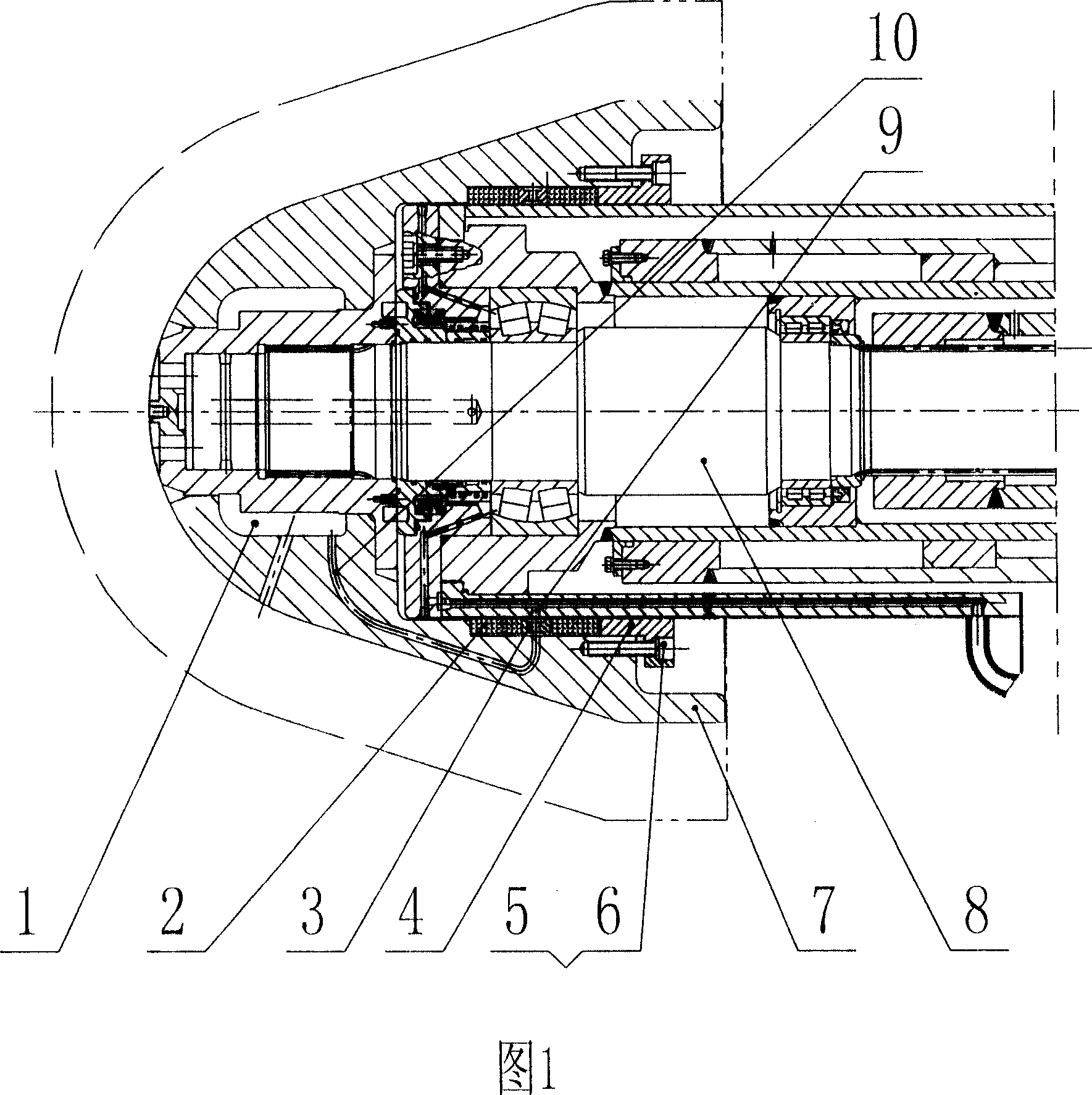

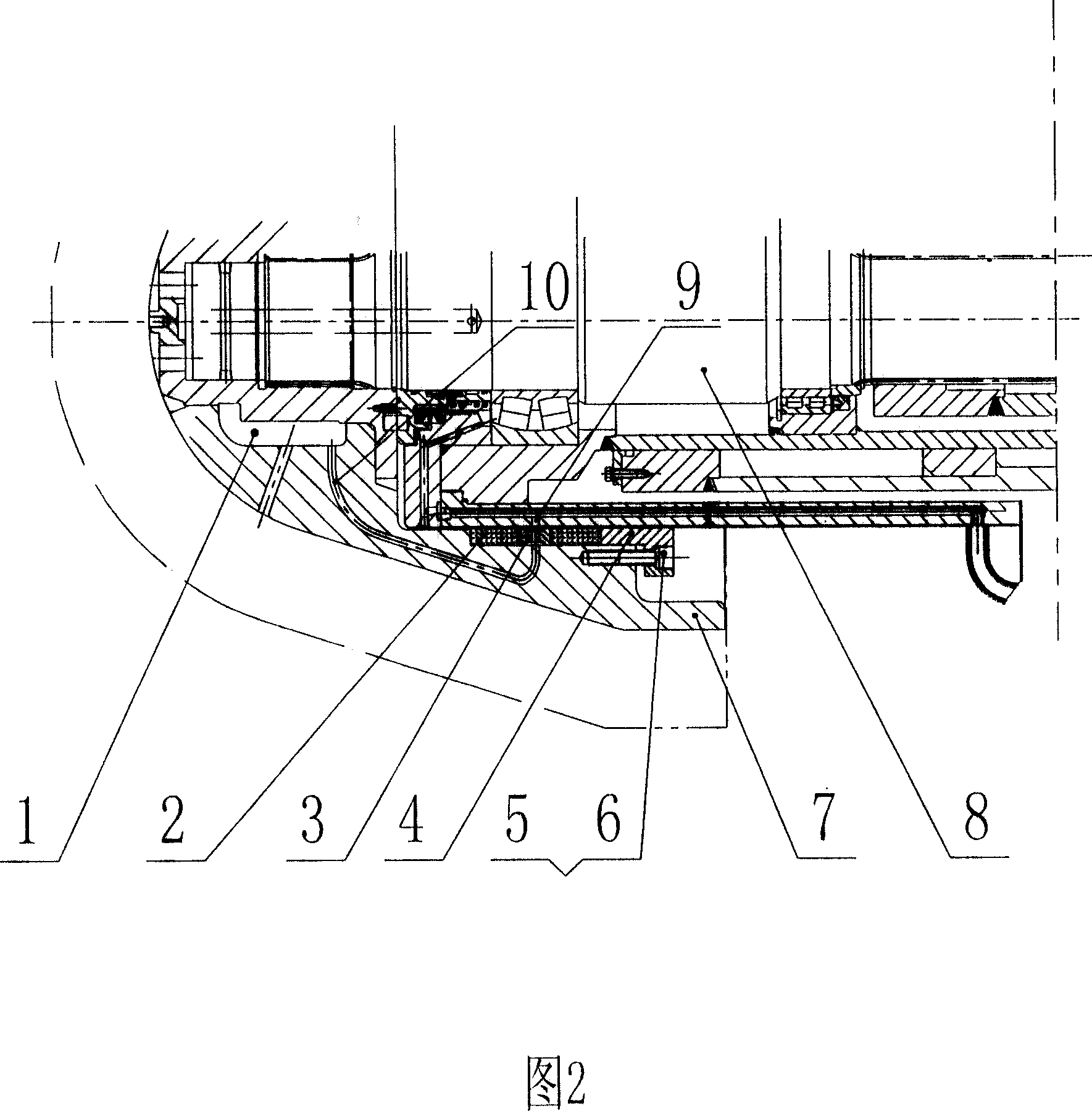

[0013] As shown in Fig. 1 and Fig. 2, the water of the cutting head of the cutting part of the cutting part of the water-sealed external roadheader of the present invention comes from the water inlet 9, and is directly injected into the water spray port 1 through the water hole 10 in the cutting head, Achieve inner spray.

[0014] In the present invention, the spray water source in the cutting head of the cutting part of the roadheader is diverted from the input of the central cutting head shaft 8 and directly injected into the outer cutting head 7 instead of passing through the cutting head shaft 8, thereby solving the problem of transporting water through the cutting head shaft 8 Defects in the waterway, water leakage and oil cavity. As shown in the figure, new parts are added: special packing for ash and slag medium 2, spacer 3, pressure ring 4, screw 5, washer 6. The special packing 2 for ash and slag medium is located between the water passage hole 10 and the water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com