Extractor with circumrotating and stabilizing type magnetic stirring

A magnetic stirring and extraction device technology, applied in solvent extraction, separation methods, chemical instruments and methods, etc., can solve problems such as unseen industrial applications, and achieve the effects of solving emulsification and entrainment, preventing emulsification, and promoting dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

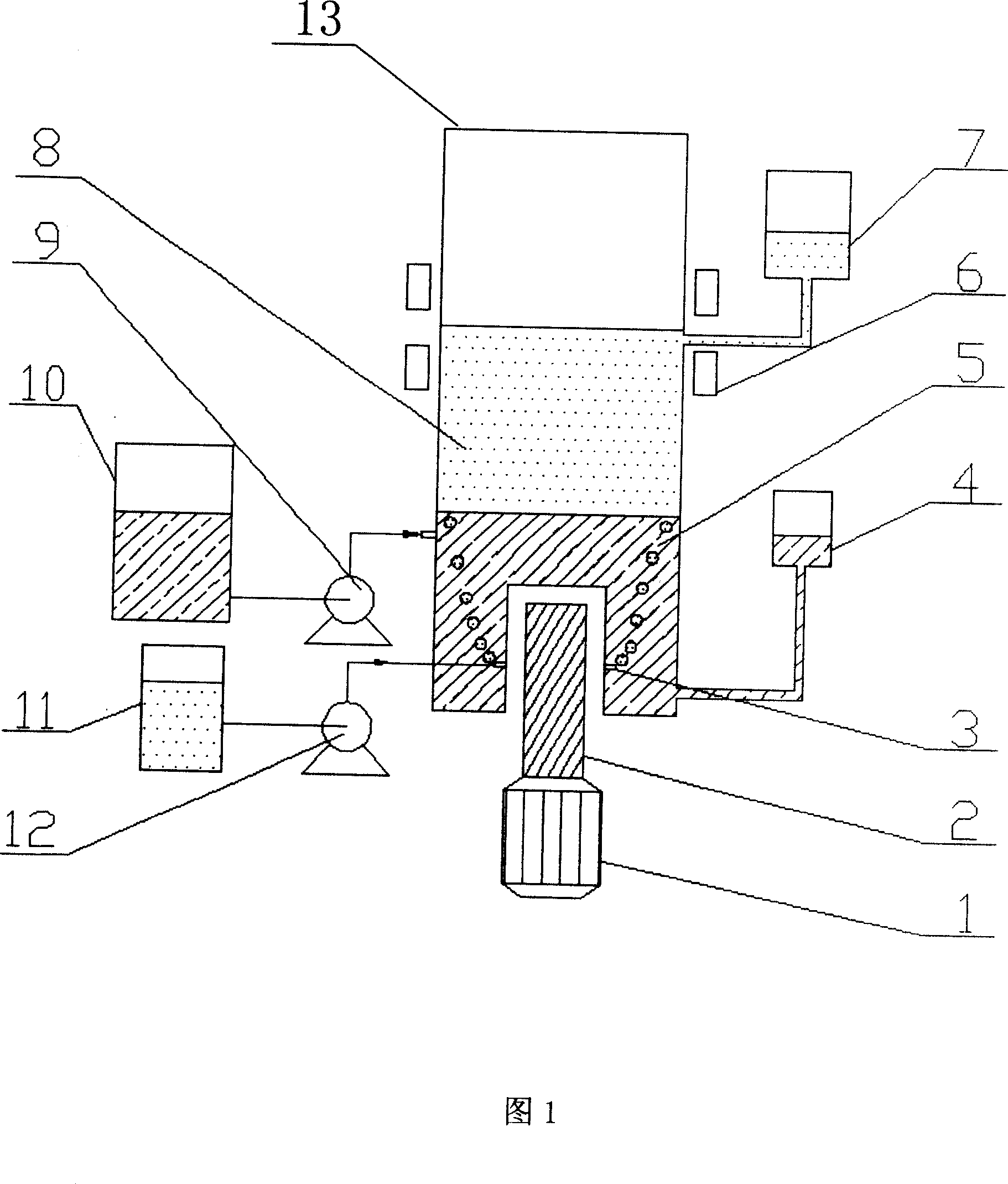

[0035] Please refer to Figure 1. The extraction device with rotating and stable magnetic stirring includes: rotating motor 1, vertical circular NdFeB permanent magnet 2, annular distributor 3, magnetic ionic liquid collecting tank 4, magnetically stabilized bed coil 6, extracted material liquid Collection tank 7, magnetic ionic liquid metering pump 9, magnetic ionic liquid storage tank 10, feed liquid storage tank 11, feed liquid metering pump 12, reaction tank 13;

[0036] The middle part of the bottom is an inwardly concave reaction tank 13, and in the groove of the bottom there is a vertical circular NdFeB permanent magnet 2 connected to the shaft of the rotary motor 1 with a magnetic field strength of 1000-3000 Oersted Have a magnetic ionic liquid outlet on the wall of the bottom one side of the reaction tank 13, and communicate with a magnetic ionic liquid collection tank 4 by pipeline; The feed liquid inlet of the magnetic ionic liquid outlet, and a magnetic ionic liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com