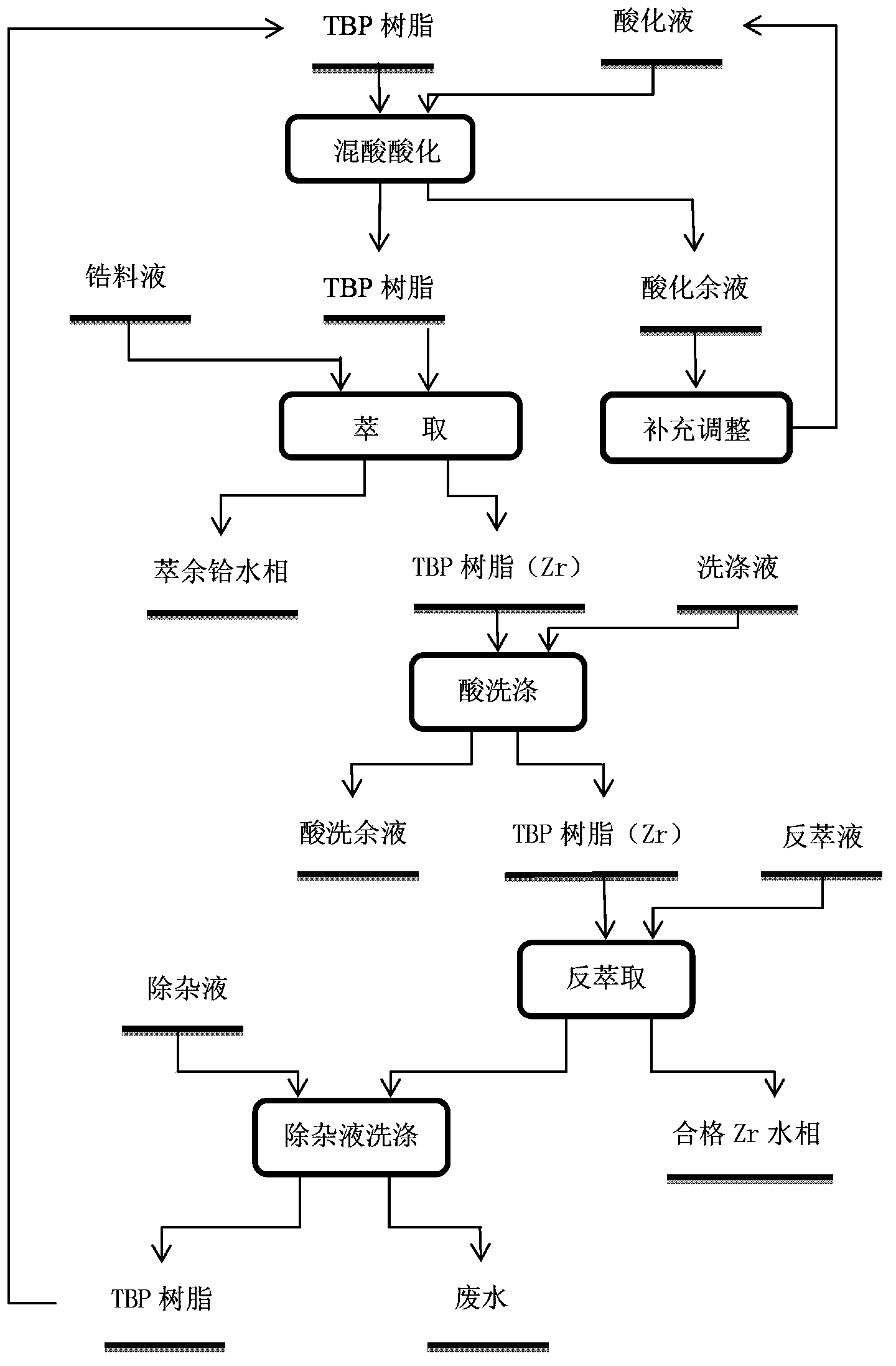

Method using tributyl phosphate resin for fractional extraction to separate zirconium and hafnium

A technology of tributyl phosphate and resin, which is applied in the field of fractional extraction and separation of zirconium and hafnium with tributyl phosphate resin, which can solve the problems of low extraction efficiency and achieve the effects of large extraction phase capacity, reduced equipment corrosion, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

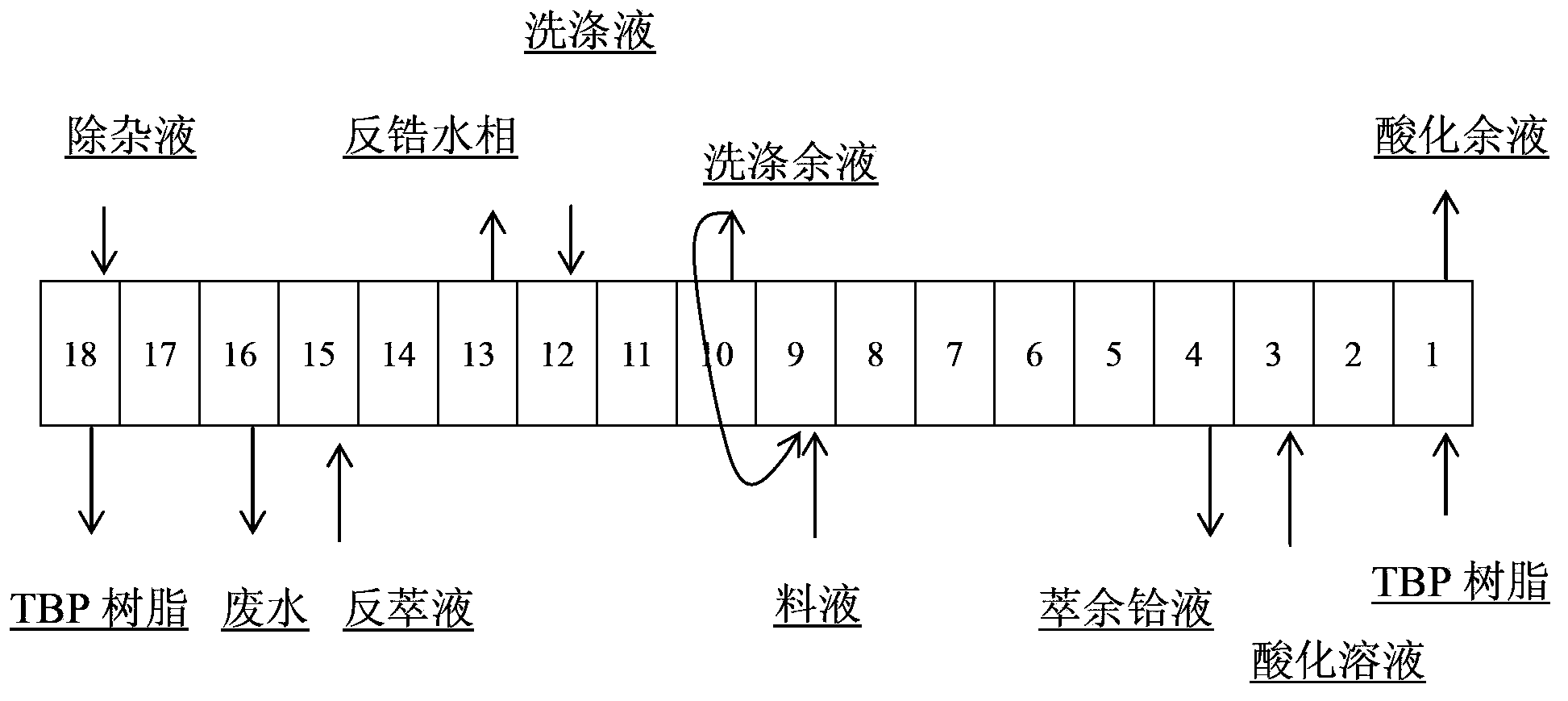

Embodiment -1

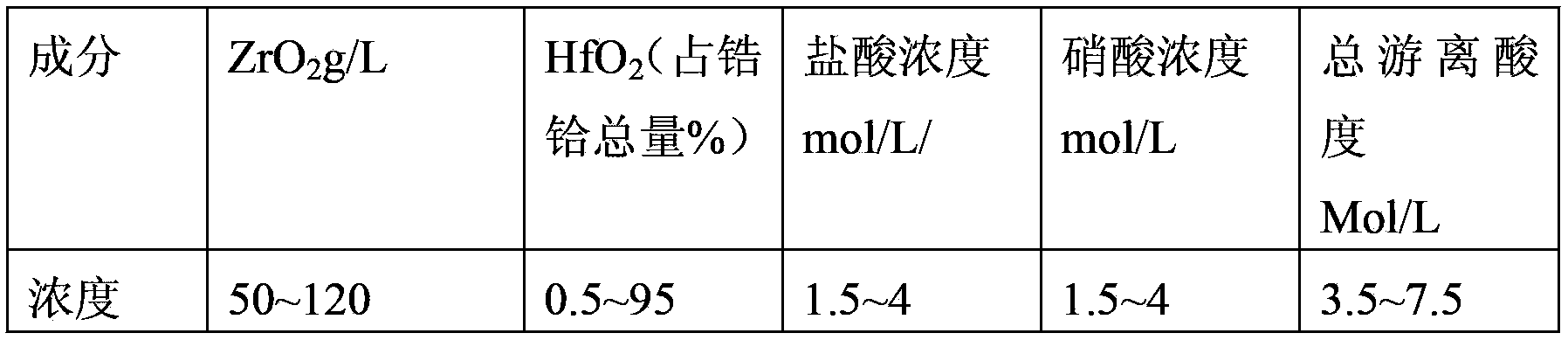

[0057] Prepare 60 liters of acidified mixed acid solution: add 15 liters of hydrochloric acid (chemically pure, acidity of concentrated hydrochloric acid is 12 mol / liter), add 11.2 liters of nitric acid (chemically pure, acidity of concentrated nitric acid is 16 mol / liter), add 33.75 liters of deionized water, Stir evenly, and measure the total free acidity of the acidifying acid to be 6.03 mol / liter.

[0058] Prepare 45 liters of feed liquid: take 4.75 kilograms of industrial grade zirconium oxychloride, put it into 31.5 liters of deionized water, stir and dissolve, after dissolving, add 3.8 liters of hydrochloric acid (chemically pure, concentrated hydrochloric acid acidity is 12 mol / liter), Add 9.7 liters of nitric acid (chemically pure, concentrated nitric acid acidity is 16 mol / liter), stir, the total free acidity of measuring feed liquid is 6.15 mol / liter, and the total concentration of zirconium dioxide and hafnium dioxide is 72.97 grams / liter, The content of hafnium di...

Embodiment -2

[0069] A method similar to Example-1 was used to prepare acid solutions of different concentrations, feed liquid, washing liquid, anti-zirconium solution, and impurity removal solution. 45% TBP resin; The total free acidity of acidifying acid is 4.52 mol / liter; The total free acidity of feed liquid is 4.02 mol / liter, and the total concentration of zirconium and hafnium (calculated as oxide) is 50 grams / liter, the percentage of hafnium dioxide It is 5.7%; the total free acidity of the washing liquid is 4.05 mol / liter; the total free acidity of the anti-zirconium solution is 1.25 mol / liter; the total free acidity of the impurity removal solution is 1.65 mol / liter; compared to the extraction phase: acidifying acid: Washing solution: stripping solution: impurity removal solution=4.8:3:1:0.5:1.

[0070] The number of separation stages and operations are the same as in Example-1, and the zirconium dioxide concentration obtained in the inverse zirconium solution is 46 grams per liter...

Embodiment -3

[0072] Adopt similar conditions and operating methods as in Example-1, the only difference is that the content of the extractant in the extraction phase is different, use 35% TBP resin, and use a comparison as the extraction phase: acidifying acid: washing liquid: stripping liquid: removing Miscellaneous liquid=3:2:1:0.5:1 ratio, the separation stages are 3 stages of acidification, 7 stages of extraction, 6 stages of washing, 5 stages of stripping, and 5 stages of impurity removal. The zirconium dioxide concentration of the obtained inverse zirconium solution is 58 g / L, the percentage of hafnium dioxide is less than 0.01%, which meets the requirement of atomic energy level zirconium oxide, and the total recovery rate of zirconium dioxide is 81%.

[0073] In the TBP resin that above-mentioned embodiment uses, resin can also select: styrene-methyl methacrylate, styrene-methyl acrylate, styrene-glyceryl trimethacrylate, styrene-ethanol dimethacrylate, Polychlorotrifluoroethylene,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

| Free acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com