Method for processing base oil of tea oil cosmetic

A processing method and base oil technology, which are applied in cosmetics, cosmetic preparations, cosmetic preparations, etc., can solve the problems of excessive alkali, increase loss and loss, and reduce product quality, and achieve acid value and peroxide value. The effect of low processing yield and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

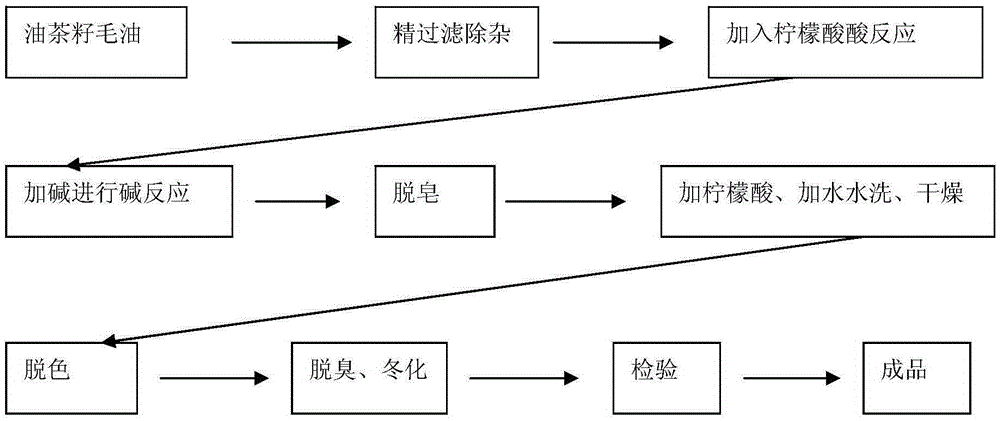

Image

Examples

Embodiment 1

[0024] Embodiment 1: The camellia oil pressed crude oil (acid value 1.5mgKOH / g) that meets the national standard is finely filtered, and the impurity content after fine filtration is less than 0.1%. At normal temperature, add 50% citric acid solution accounting for 2% of the oil weight to carry out acid reaction, and carry out vigorous stirring. The reaction time is 150min; After 30 minutes, the reacted camellia oil was heated to 75°C, and the oil and soap were separated; the tea oil after de-soaping was added with acid, and washed with water; before washing, 50% citric acid aqueous solution accounting for 0.02% of the oil weight was added and mixed evenly, and The oil temperature is increased to 85°C, the water temperature is 90°C, and the amount of water added accounts for 10% of the oil weight; after washing the oil to remove soap, vacuum drying, and then polishing and filtering, so that the moisture content of the dry oil is less than 0.01%, and the impurity content is less...

Embodiment 2

[0025] Embodiment 2: Finely filter the pressed camellia oil (acid value 2.0 mgKOH / g) that meets the national standard, and the impurity content after finely filtering is less than 0.1%. Under normal temperature, add 52% citric acid solution that accounts for 1.8% of oil weight to carry out acid reaction, and carry out strong stirring, and the reaction time is 180min; After 25 minutes, the reacted camellia oil was heated to 75°C, and the oil and soap were separated; the tea oil after de-soaping was added with acid, and washed with water; before washing, 52% citric acid aqueous solution accounting for 0.02% of the oil weight was added and mixed evenly, and The oil temperature is increased to 87°C, the water temperature is 92°C, and the amount of water added accounts for 12% of the oil weight; after the oil is washed with water to remove the soap, it is vacuum-dried, and then polished and filtered, so that the moisture content of the dried oil is less than 0.01%, and the impurity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com