Compound ferric sulfate extractant

A technology for compounding extractants and extractants, which is applied to aluminum sulfate, liquid solution solvent extraction, aluminum-sulfur compounds, etc., can solve the problems of difficult filtration, low treatment efficiency, complicated operation, etc., and achieves cost saving and shortening extraction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

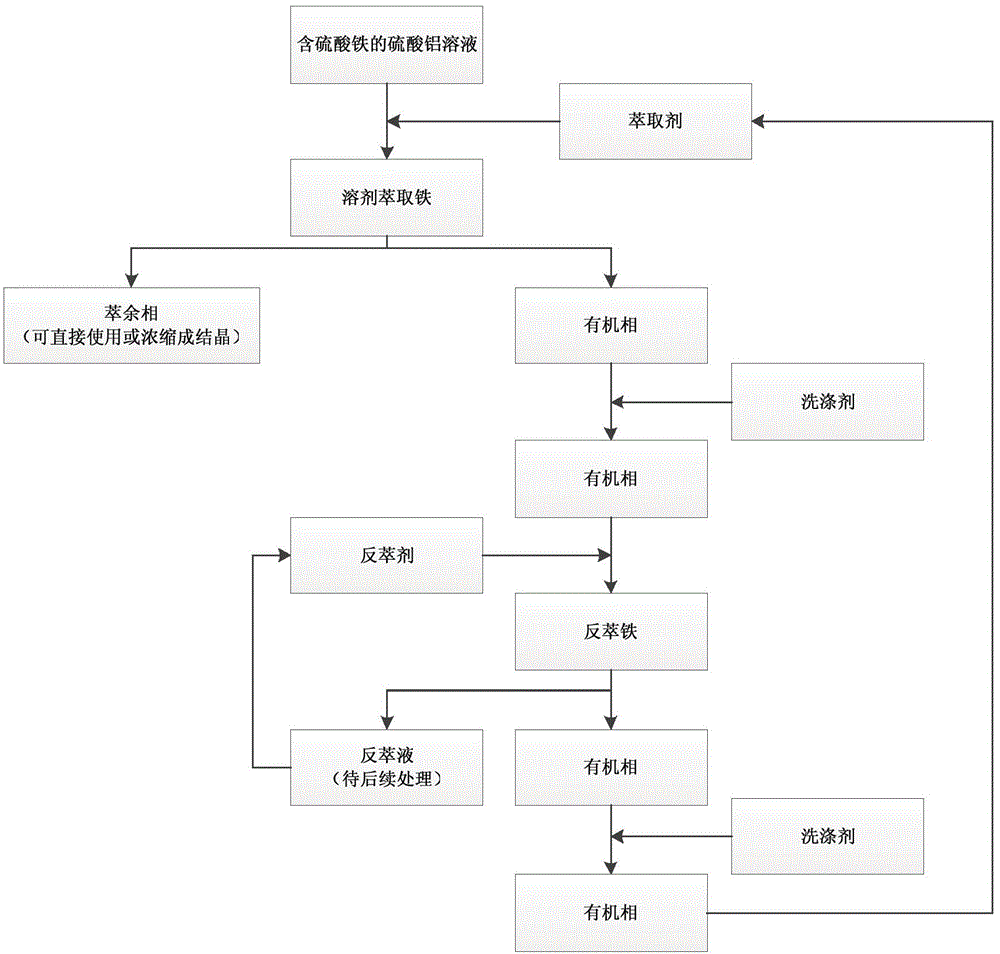

Method used

Image

Examples

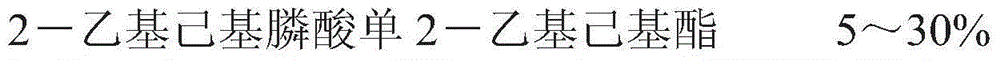

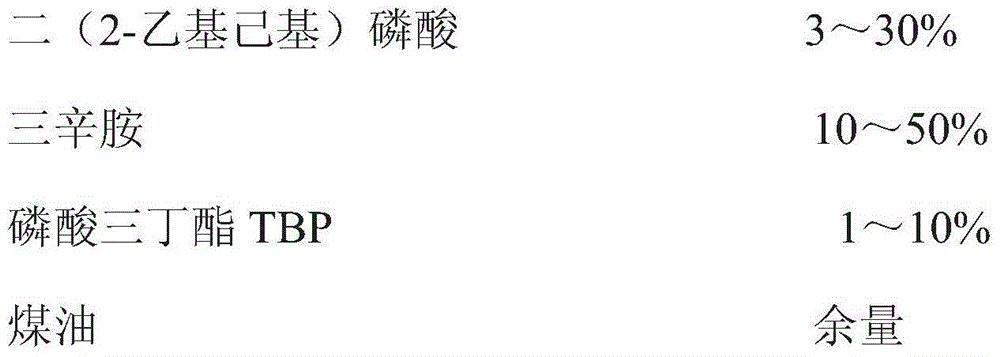

Embodiment 1

[0032] Add 150mL of aluminum sulfate solution into a spherical separatory funnel with a capacity of 500mL, in which Al 2 o 3 108.47g / L content, Fe 2 o 3 The content is 2.71g / L, and the pH value of the solution is 1.83. Add 150mL and the composition is: 20% 2-ethylhexylphosphonic acid mono-2-ethylhexyl ester, 10% di(2-ethylhexyl) phosphoric acid, 34 trioctylamine %, TBP6%, and kerosene 30% compound extractant were fully mixed at room temperature for 15-20 minutes, and then allowed to stand and separate for 10-25 minutes. The recovery rate of aluminum in the aqueous phase was 97.11%, and the removal rate of iron was 97.58%. The organic phase is back-extracted by 1mol / L dilute sulfuric acid 1:1, and the back-extraction rate is greater than 99%.

Embodiment 2

[0034] Add 150mL of aluminum sulfate solution into a spherical separatory funnel with a capacity of 500mL, in which Al 2 o 3 108.47g / L content, Fe 2 o 3 The content is 2.71g / L, the pH value of the solution is 1.83, and 150mL is added to form: 2-ethylhexylphosphonic acid mono-2-ethylhexyl ester 15%, di(2-ethylhexyl) phosphoric acid 20%, trioctylamine 45% %, TBP4%, kerosene 16% compound extractant was fully mixed at room temperature for 15-20 minutes, and then allowed to stand for 10-25 minutes. The recovery rate of aluminum in the aqueous phase was 96.11%, and the removal rate of iron was 98.58%. The organic phase is back-extracted by 1mol / L dilute sulfuric acid 1:1, and the back-extraction rate is greater than 99%.

Embodiment 3

[0036] Add 150mL of aluminum sulfate solution into a spherical separatory funnel with a capacity of 500mL, in which Al 2 o 3 112.73g / L content, Fe 2 o 3 The content is 2.98g / L, the pH value of the solution is 1.87, and 180mL is added to form: 2-ethylhexylphosphonic acid mono-2-ethylhexyl ester 30%, di(2-ethylhexyl) phosphoric acid 15%, trioctylamine 20% %, TBP2%, and kerosene 33% compound extractant were fully mixed at room temperature for 20-25 minutes, and then allowed to stand for 10-25 minutes to separate layers. The recovery rate of aluminum in the aqueous phase was 97.29%, and the removal rate of iron was 97.79%. The organic phase is back-extracted by 1mol / L dilute sulfuric acid 1:1, and the back-extraction rate is greater than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com