Method for purifying sugammadex sodium

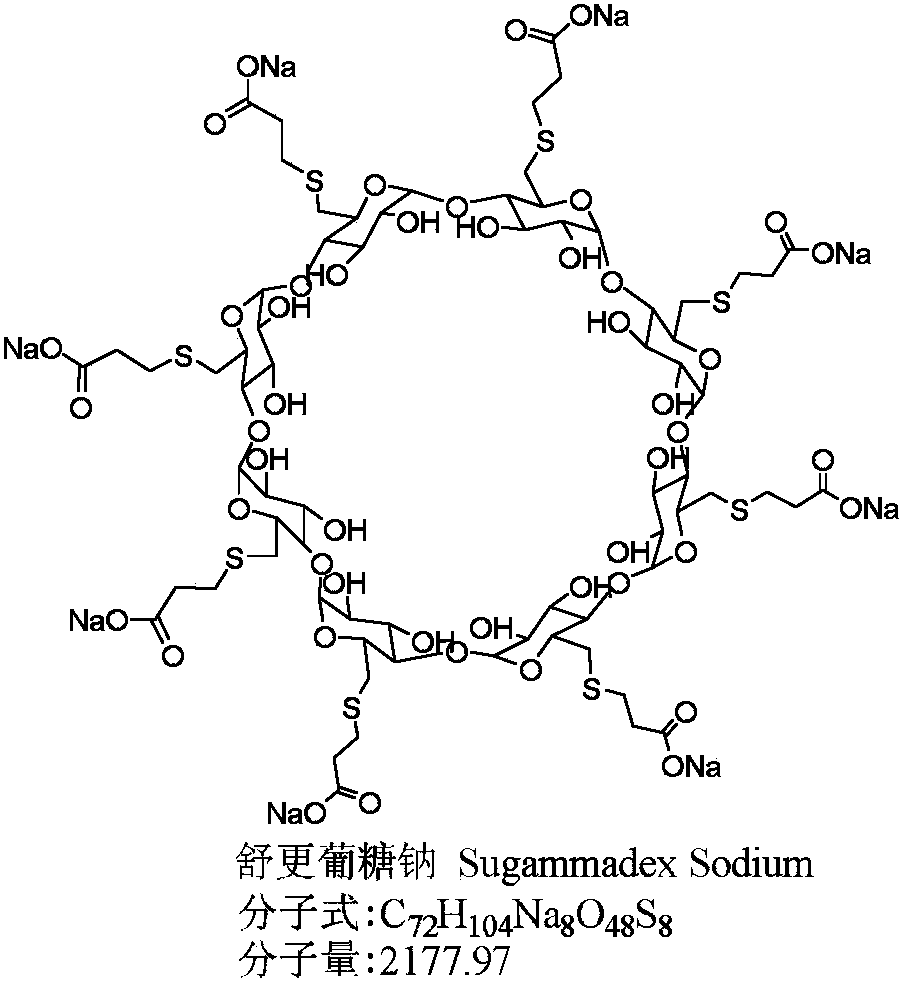

A technology of sugammadex sodium and purification method, which is applied in the field of drug synthesis, and can solve problems such as the influence of cyclodextrin substrate stability, easy generation of oxidation or other decomposed impurities, and influence on the drug safety of sugammadex sodium products , to achieve a significant effect of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0086] Preparation example: Preparation of crude sugammadex sodium:

[0087] Iodo γ-cyclodextrin can be prepared by iodination of γ-cyclodextrin. For the preparation method, refer to the literature Methods for Selective Modifications of Cyclodextrins, Chem. Rev. 1998, 98, 1977-1996.

[0088] Sodium hydride (58.8 g, 60%) was added to dry DMF (2.6 L) under nitrogen protection and ice bath. Slowly add the mixed solution of triphenylphosphine (12.3g)-3-mercaptopropionic acid (78.2g)-DMF (0.5L) dropwise at 0-10°C, heat up to 65-75°C and react under stirring, then slowly Add the mixed solution of periodo γ-cyclodextrin (100g)-triphenylphosphine (3.9g)-DMF (0.7L) dropwise, and continue stirring for about 6h. The reaction solution was lowered to 0-10°C, water (0.6 L) was added, and the temperature was raised to 55-70°C for about 3 hours under stirring. Cool the reaction solution to room temperature, filter with suction, dissolve the filter cake with water (1.0L), filter with diatoma...

Embodiment 1

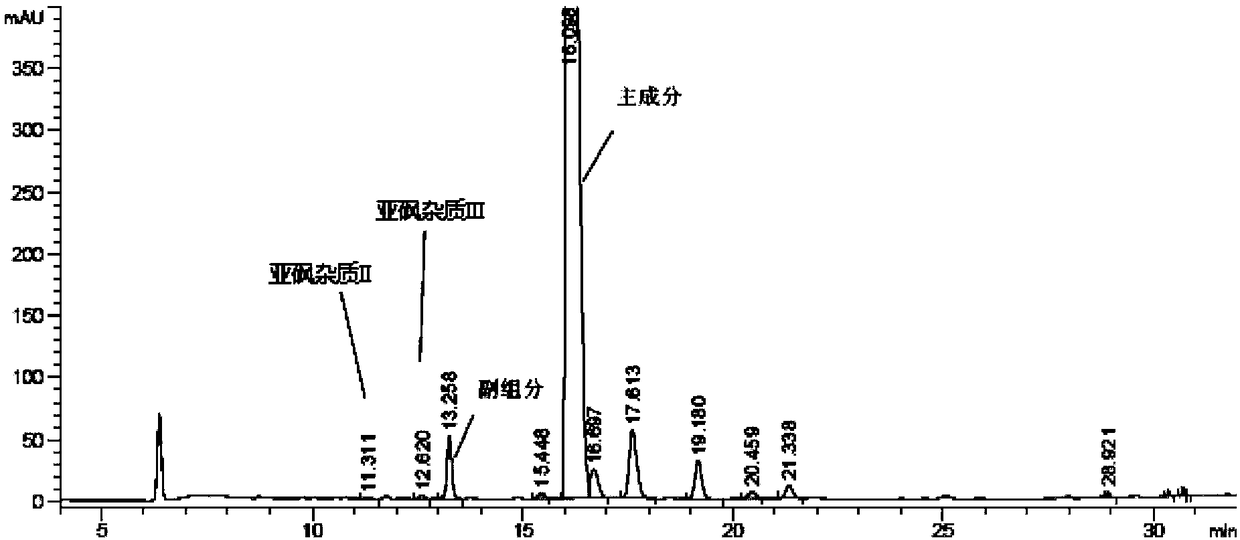

[0089] Embodiment 1: Purification of sugammadex sodium

[0090] Step (1): Under nitrogen atmosphere, add triethylamine (0.8L) to acetic acid (4L), stir to cool down to room temperature, continue to add tri-p-methylphenylphosphine (8.4g, 0.1eq), sugammadex Sodium sugar crude product (0.6Kg, 1eq), stirred until completely dissolved, controlled temperature at 20-40°C, continued to stir for 1-5h, added dropwise acetone (2.4L) to force crystallization, stirred for 1-2h, and dried by suction to obtain More gluconic acid (0.49Kg, HPLC total purity 98.60%).

[0091] Step (2): Under nitrogen atmosphere, add tri-p-methylphenylphosphine (7.4g, 0.1eq) to DMF (0.98L), and continue to add sugammadex (0.49Kg, 1eq ), heated to 35-50°C, stirred until completely dissolved, added dropwise acetonitrile (1.96L) at 35-50°C under temperature control, lowered to room temperature, stirred for 1-2 hours, and dried by suction to obtain purified sugammadex (0.44Kg, HPLC total purity 99.42%).

[0092] ...

Embodiment 2

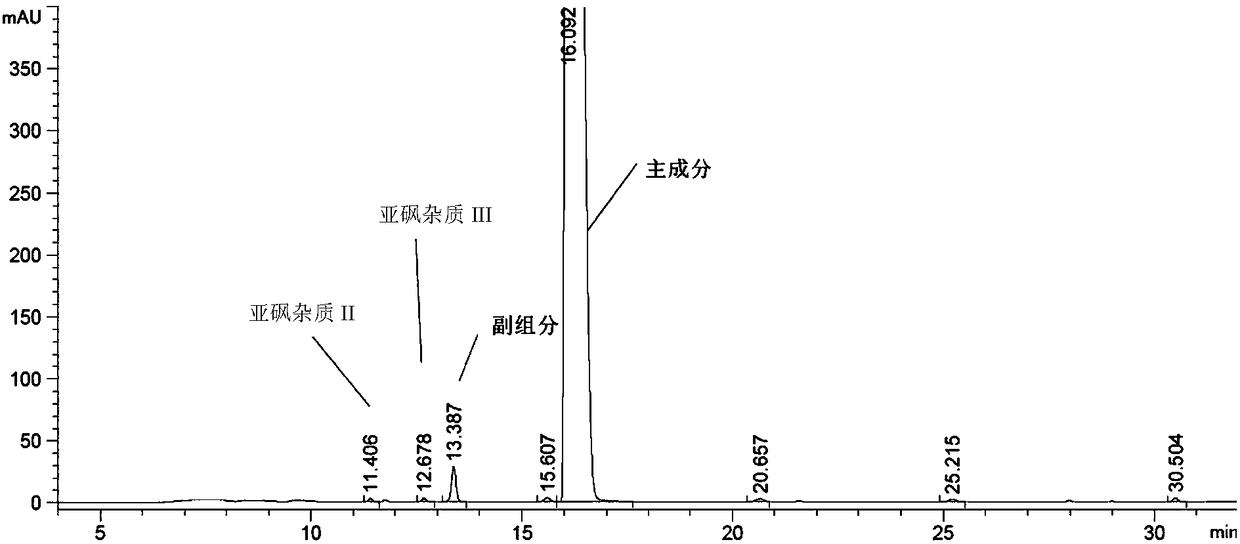

[0093] Embodiment 2: Purification of sugammadex sodium

[0094] Step (1): Add triethylamine (0.5L) to acetic acid (5.5L), stir down to room temperature, continue to add tri-p-methylphenylphosphine (84g, 1eq), crude sugammadex sodium (0.6 Kg, 1eq), stirred until completely dissolved, controlled the temperature at 20-40°C, continued to stir for 1-5h, added dropwise acetone (2.4L) to force crystallization, stirred for 1-2h, and dried by suction to obtain sugammadex ( 0.4Kg).

[0095] Step (2): Add tri-p-methylphenylphosphine (7.1g, 0.1eq) to DMF (0.98L), continue to add sugammadex (0.4Kg, 1eq) obtained in step (1), and heat up to Stir at 35-50°C until completely dissolved, add acetonitrile (1.96L) dropwise, lower to room temperature, stir for 1-2 hours, then filter and dry to obtain purified sugammadex (0.4Kg).

[0096] Step (3): Add the sugammadex (0.4Kg, 1eq) obtained in step (2) to the sodium hydroxide (0.09Kg, 10eq)-water (1.76L) solution under ice bath, warm up to room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com