Amphion type amino silicone oil and preparation method thereof

A technology of amino silicone oil and zwitterion, applied in the field of zwitterionic amino silicone oil and its preparation, can solve the problems of easy yellowing of fabrics, and achieve the effects of reducing yellowing, improving stability and lasting sterilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

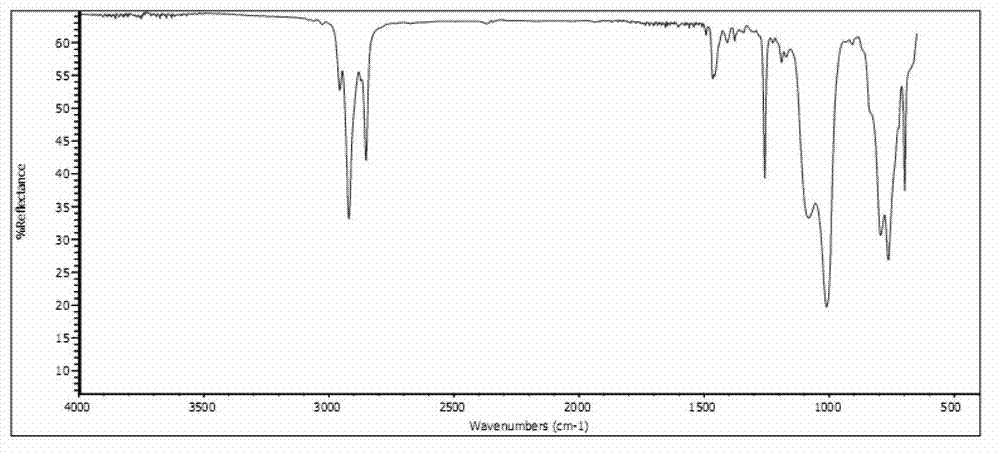

Image

Examples

Embodiment 1

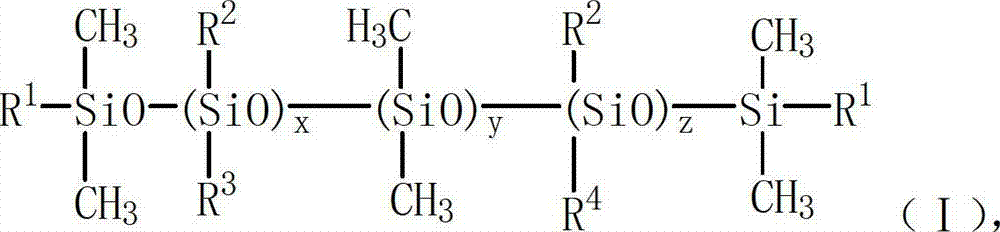

[0037] The structural formula of a kind of zwitterionic amino silicone oil is:

[0038]

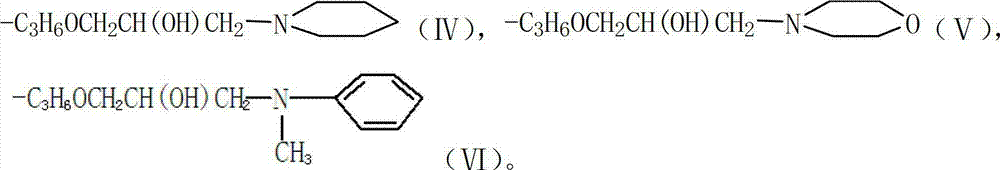

[0039] in:

[0040]

[0041] x, y, z are all positive integers, 5≤x+y+z≤1000.

[0042] The preparation method of above-mentioned zwitterionic amino silicone oil, concrete steps are as follows:

[0043](1) Add 70.03g of D4 (octamethylcyclotetrasiloxane) and 0.37g of MM (hexamethyldisiloxane) into a dry reaction flask equipped with a thermometer, condenser tube, stirring paddle, and nitrogen protection , heated up to 80°C; add glycidyloxypropylmethyldimethoxysilane solution (29.60g glycidoxypropylmethyldimethoxysilane, hydrolyzed by adding 26.8g water), and stir at constant temperature for 1 hour Finally, distill methanol and water, etc.; add 0.01g KOH, heat up to 130°C, and after constant temperature reaction for 8 hours, vacuumize to evaporate low boilers; cool down to 80°C, add 0.011g acetic acid for neutralization, and continue to cool down to 60°C °C, filter, and discharge to ...

Embodiment 2

[0049] The structural formula of a kind of zwitterionic amino silicone oil is:

[0050]

[0051] in:

[0052]

[0053] x, y, z are all positive integers, 5≤x+y+z≤1000.

[0054] The preparation method of above-mentioned zwitterionic amino silicone oil, concrete steps are as follows:

[0055] (1) Add 77.55g (octamethylcyclotetrasiloxane) D4 and 1.02g dodecyl-terminated dimethyl silicone oil to a dry reaction flask equipped with a thermometer, condenser, stirring paddle and protected by nitrogen gas (Viscosity 5CST), heat up to 80°C; add glycidyloxypropyltrimethoxysilane solution (21.43g glycidoxypropyltrimethoxysilane, hydrolyzed by adding 16.3g water), stir at constant temperature for 0.5 hours, Evaporate methanol and water, etc.; add 0.01g NaOH, heat up to 100°C, and react at constant temperature for 36 hours, then vacuumize to evaporate low boilers; cool down to 80°C, add 0.015g acetic acid for neutralization, continue to cool down to 60°C, Filter and discharge to ob...

Embodiment 3

[0062] The structural formula of a kind of zwitterionic amino silicone oil is:

[0063]

[0064] in:

[0065] R 3 -C 3 h 6 CH 2 H(OH)CH 2 N(CH 2 h 3 ) 2

[0066]

[0067] x, y, z are all positive integers, 5≤x+y+z≤1000.

[0068] The preparation method of above-mentioned zwitterionic amino silicone oil, concrete steps are as follows:

[0069] (1) Add 81.19g of D4 (octamethylcyclotetrasiloxane) and 0.44g of 1,1,3,3-tetramethyl to a dry reaction flask equipped with a thermometer, condenser tube, stirring paddle, and nitrogen protection Base-1,3-dimethoxydisiloxane, heat up to 80°C; add glycidoxypropylmethyldiethoxysilane solution (18.37g glycidoxypropylmethyldiethoxysilane , hydrolyzed by adding 13.3g of water), after stirring at constant temperature for 2 hours, distill ethanol and water, etc.; Boiling matter: cool down to 80°C, add 0.013g of acetic acid to neutralize, continue to cool down to 60°C, filter, and discharge to obtain a transparent viscous liquid, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Ammonia value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com