Super-soft/smooth block silicon oil and preparation method thereof

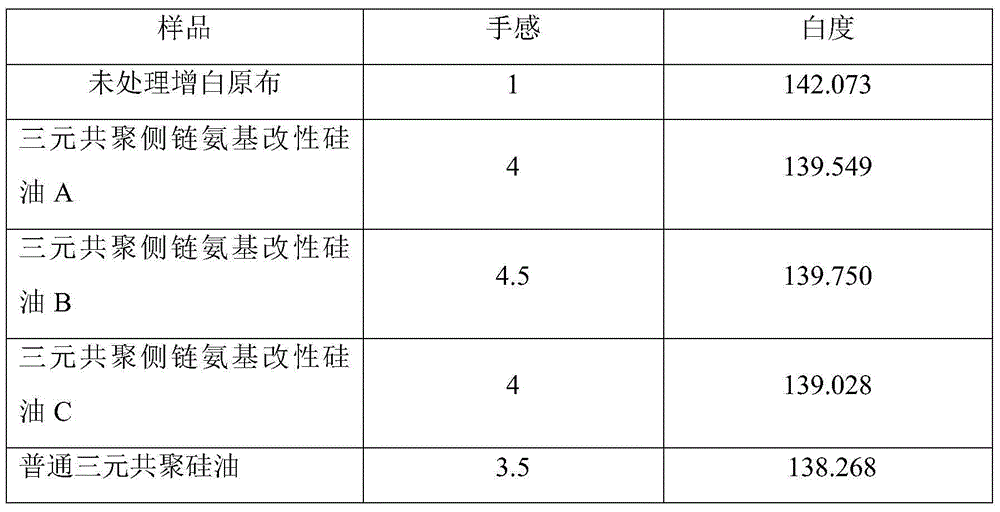

A technology of block silicone oil and silicone oil, used in textiles, papermaking, fiber processing, etc., can solve the problems of softness, smoothness, poor resilience, insignificant effect, and complexity, achieve good stability, and solve the problem of easy demulsification. , the best soft, fluffy and smooth effect and whiteness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

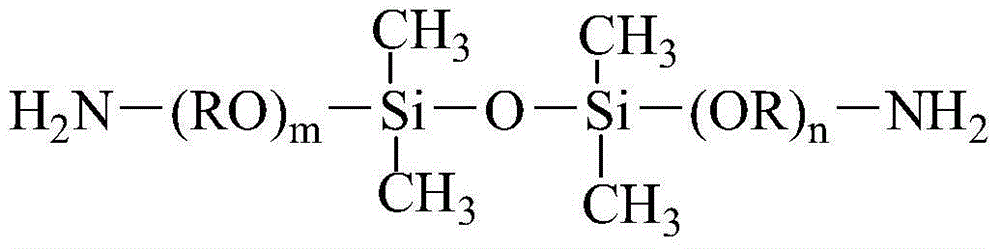

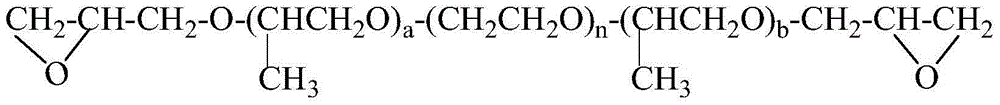

Method used

Image

Examples

Embodiment 1

[0031] In the first step, put octamethylcyclotetrasiloxane and amino coupling agent into the reaction kettle in proportion to 100:1 (mass ratio), stir and heat up, heat to 80-85°C, and add 0.02% of the total mass It is 30% potassium hydroxide aqueous solution, continue to heat up to 140-145°C, keep it warm for 3-4h, then cool down to 120°C and vacuumize the low molecular weight substance to obtain a colorless transparent viscous substance, which is the side chain amino-modified silicone oil Intermediate; in the second step, put the side-chain amino-modified silicone oil intermediate and the amino-terminated polyether coupling agent into the reaction kettle at a ratio of 100:8 (mass ratio), heat to 80-85°C, add the side-chain amino-modified 0.1% potassium hydroxide aqueous solution with a concentration of 30% of the mass of the silicone oil intermediate and the amino-terminated polyether coupling agent, continue to heat up to 140-145°C, keep the temperature for 3-4h, and then co...

Embodiment 2

[0033] In the first step, put octamethylcyclotetrasiloxane and amino coupling agent into the reaction kettle according to the ratio of 100:3 (mass ratio), stir and heat up, heat to 80-85°C, and add 0.02% of the total mass Tetramethylammonium hydroxide, continue to heat up to 110-120°C, keep warm for 3-4h, then heat up to 145°C to remove low boilers and catalysts by vacuuming, and obtain a colorless transparent viscous product, which is side chain amino-modified silicone oil Intermediate; in the second step, put the side-chain amino-modified silicone oil intermediate and the amino-terminated polyether coupling agent in a ratio of 100:5 (mass ratio) into the reaction kettle, heat to 80-85°C, add the side-chain amino-modified Tetramethylammonium hydroxide with 0.1% quality of silicone oil intermediate and amino-terminated polyether coupling agent, continue to heat up to 110-120°C, keep warm for 3-4h, then heat up to 145°C and vacuumize to remove low boilers and catalysts, Obtain ...

Embodiment 3

[0035] In the first step, put octamethylcyclotetrasiloxane and amino coupling agent into the reaction kettle according to the ratio of 100:2 (mass ratio), stir and heat up, heat to 80-85°C, and add 0.02% of the total mass Tetramethylammonium hydroxide, continue to heat up to 110-120°C, keep warm for 3-4h, then heat up to 145°C to remove low boilers and catalysts by vacuuming, and obtain a colorless transparent viscous product, which is side chain amino-modified silicone oil Intermediate; in the second step, put the side-chain amino-modified silicone oil intermediate and the amino-terminated polyether coupling agent in a ratio of 100:10 (mass ratio) into the reaction kettle, heat to 80-85°C, add the side-chain amino-modified Tetramethylammonium hydroxide with 0.1% quality of silicone oil intermediate and amino-terminated polyether coupling agent, continue to heat up to 110-120°C, keep warm for 3-4h, then heat up to 145°C and vacuumize to remove low boilers and catalysts, Obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com