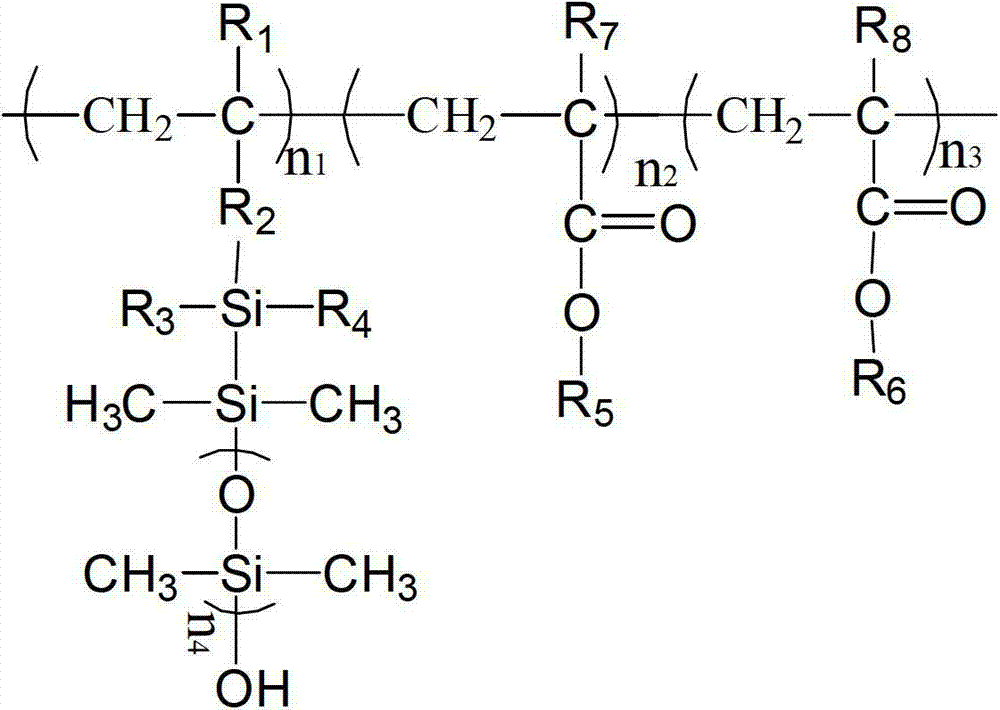

(Methyl) acrylic resin with high organic silicon content and preparation method thereof

A technology with acrylic resin and silicon content, applied in the direction of coating, etc., can solve the problems of unsustainable modification effect, poor compatibility, disappearance, etc., and achieve improved water resistance, improved stain resistance, and good elongation at break The effect of rate and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

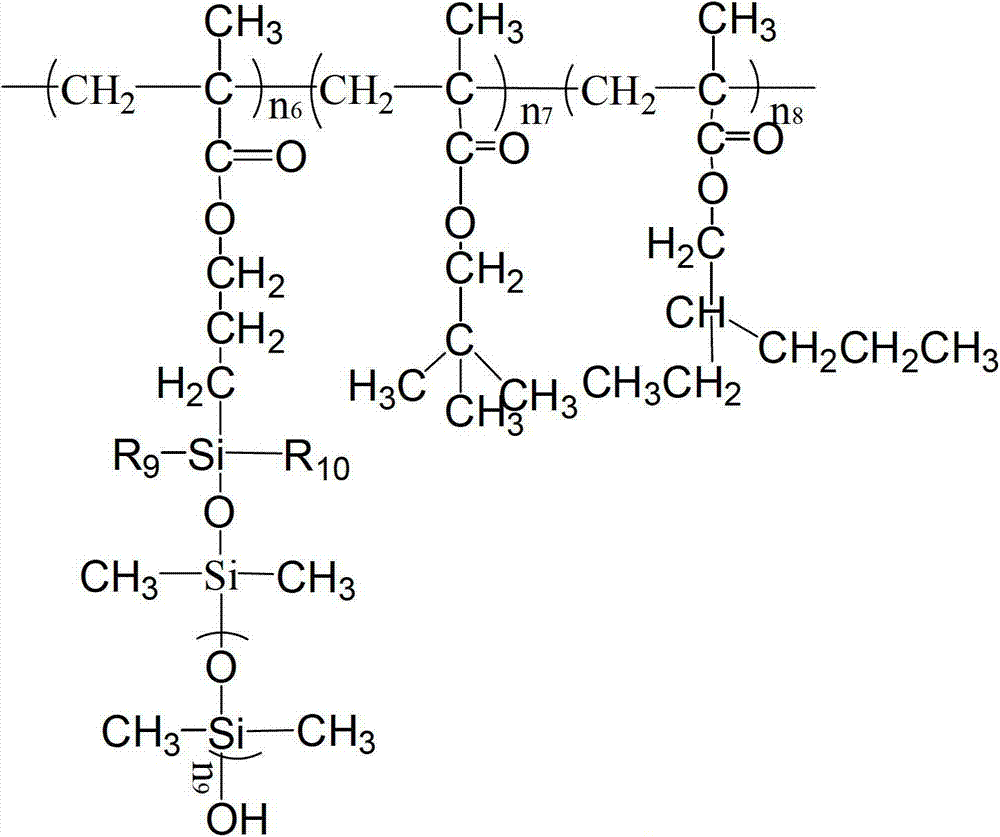

Embodiment 1

[0027] (1) Add 80g of deionized water, 3g of dodecylbenzenesulfonic acid (DBSA), 2g of alkylphenol polyoxyethylene ether into a four-neck flask equipped with a stirrer, thermometer, condenser tube and nitrogen gas inlet tube (NP-9), 10.4g of octamethylcyclotetrasiloxane, blowing nitrogen, reacting at 70°C for 9h, then adding 2.5g of γ-methacryloxypropyltrimethoxysilane (KH-570), React at 75°C for 9 hours to obtain a long-chain siloxyvinyl siloxane emulsion, take it out and cool it to room temperature, then add the obtained emulsion dropwise to ethanol, break the emulsion by ultrasonic vibration, and pour off the supernatant to obtain a long-chain siloxane Vinyl siloxane.

[0028] (2) Add 3.1g of isobutyl methacrylate, 9.4g of isooctyl methacrylate, 4.5g of the long Chain siloxyvinyl siloxane, 28g methyl ethyl ketone, 0.4g azobisisobutylcyanide, blow nitrogen, react at 60°C for 6h, and then air-cool the material to obtain a (meth)acrylic resin with high organosilicon content ...

Embodiment 2

[0035] (1) Add 110g of deionized water, 4g of dodecylbenzenesulfonic acid (DBSA), 2g of alkylphenol polyoxyethylene ether into a four-neck flask equipped with a stirrer, thermometer, condenser tube and nitrogen gas inlet tube (NP-9), 25.4g of octamethylcyclotetrasiloxane, blowing nitrogen, reacting at 75°C for 7h, then adding 4.5g of vinyltrimethoxysilane, reacting at 80°C for 7h, to obtain long-chain siloxane Base vinyl siloxane emulsion, take it out and cool it to room temperature, then add the obtained emulsion dropwise into ethanol, ultrasonically vibrate to break the emulsification, pour off the supernatant, and obtain long-chain siloxy vinyl siloxane.

[0036] (2) Add 10.4g of methyl methacrylate, 30.9g of butyl acrylate, and 20.5g of the long-chain siloxyl group obtained in step (1) into a reaction vessel equipped with a stirrer, a thermometer, a condenser tube and a nitrogen gas inlet tube. Vinyl siloxane, 79g methyl ethyl ketone, 1.6g azobisisobutyrocyanide, blowing n...

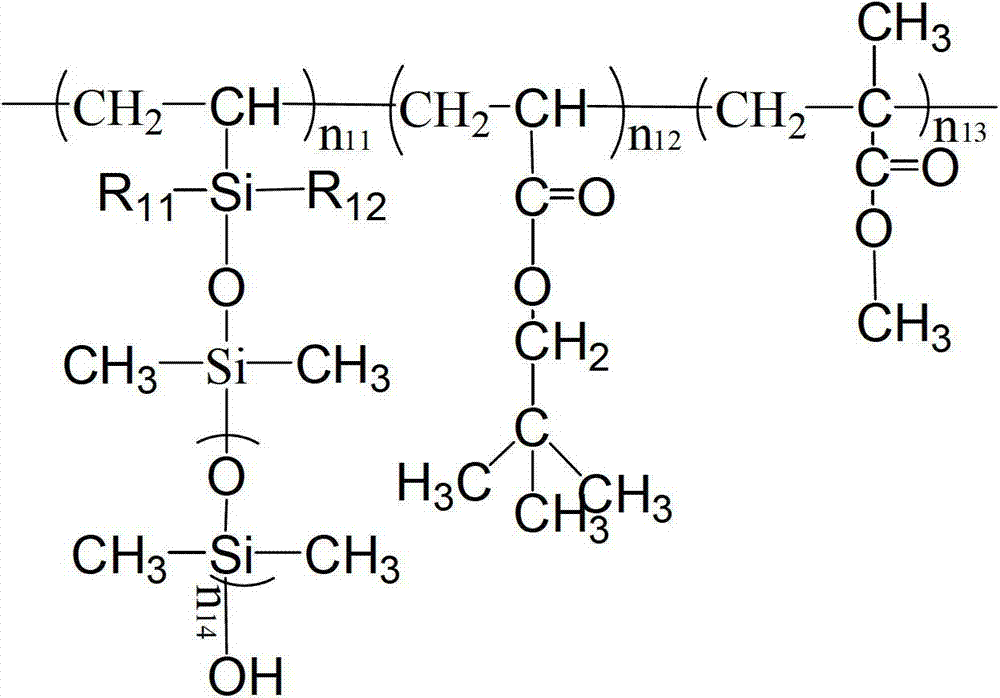

Embodiment 3

[0043] (1) Add 120g of deionized water, 4g of dodecylbenzenesulfonic acid (DBSA), 2g of alkylphenol polyoxyethylene ether to a four-neck flask equipped with a stirrer, thermometer, condenser tube and nitrogen gas inlet tube (NP-9), 30.4g of octamethylcyclotetrasiloxane, blow nitrogen, react at 80°C for 5h, then add 5.3g of vinyltriethoxysilane, react at 85°C for 5h, to obtain long-chain siloxane Base vinyl siloxane emulsion, take it out and cool it to room temperature, then add the obtained emulsion dropwise into ethanol, ultrasonically vibrate to break the emulsification, pour off the supernatant, and obtain long-chain siloxy vinyl siloxane.

[0044](2) Add 16.2g of methyl acrylate, 26.6g of ethyl acrylate, and 30.5g of the long-chain siloxy vinyl obtained in step (1) into a reaction vessel equipped with a stirrer, a thermometer, a condenser tube and a nitrogen gas inlet tube Siloxane, 92g methyl ethyl ketone, 2.4g azobisisobutyrocyanide, blowing nitrogen, reacting at 68°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com