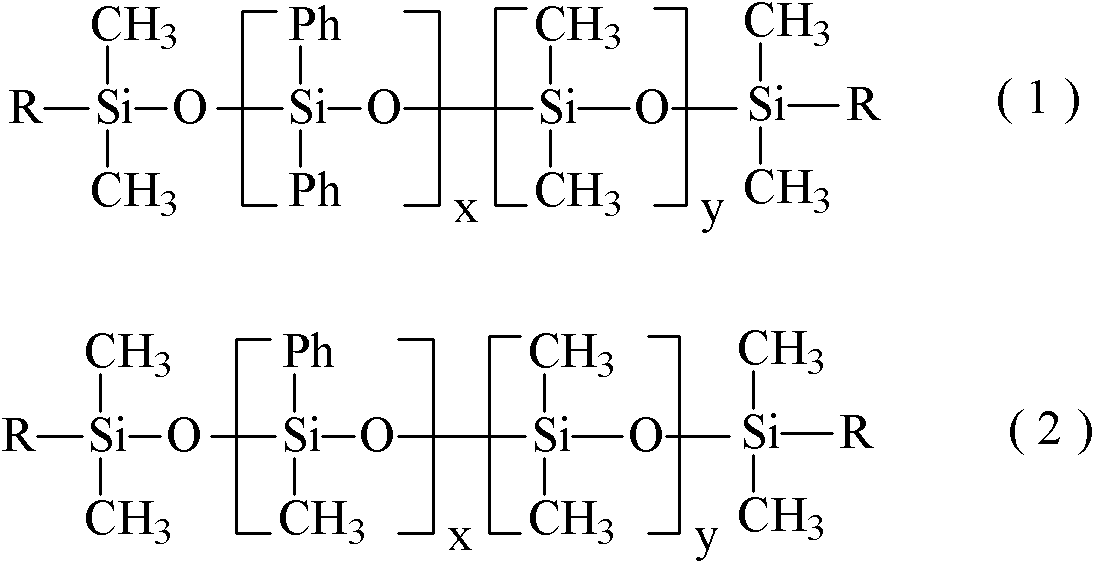

Poly(diphenyl-dimethyl siloxane) with terminals sealed by alkyloxy groups, and preparation method thereof

A technology of polydiphenyldimethylsiloxane and polydimethylsiloxane, which is applied in the field of silicone materials, and can solve the problem of storage stability and heat resistance decline, affecting product transparency, and ring-opening reactivity Low-level problems, to achieve the effect of improving quality and transparency, improving storage stability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0056] Example 2, Preparation of 2# end-capping agent-polydimethylsiloxane whose end group contains two methoxy groups

[0057] Add the DMC of the methyltrimethoxysilane (KBM13) of 110g and 1000g in the reaction bottle, other raw material addition and implementation method are the same as embodiment 1, obtain colorless and transparent, colorless after polymerization, neutralization, filtration, take off. Dimethicone containing two methoxyl groups at the end of the odor. The viscosity of gained product is 22mPa s, and volatile matter content is 0.20%, and refractive index n D 20 is 1.4035.

Embodiment 3

[0058] Example 3, Preparation of Target Product-Methoxy-terminated Polydiphenyldimethylsiloxane

[0059] Add 65g of octaphenylcyclotetrasiloxane (D 4 Ph2 ) and the methoxy-terminated polydimethylsiloxane (hereinafter referred to as 1# end-capping agent) that the embodiment 1 of 300g obtains, then add silicon alkoxide potassium salt catalyst 0.2g and dimethyl sulfoxide (DMSO) 1.5 g. After sealing the reaction system, start stirring, and raise the temperature to 150°C. After about 10 minutes, the solid powder in the reaction bottle almost completely disappears, and the viscosity rises. After being constant for 4 hours, remove the heat source and start to cool down.

[0060] Add 0.3g of propionic acid to the reaction mixture cooled to 40°C, stir for 1 hour, transfer to a filter, pressurize to 0.15Mpa at room temperature, filter out solid impurities such as potassium acetate with ordinary filter paper, and obtain a colorless and transparent of the filtrate.

[0061] Transfer t...

Embodiment 4

[0062] Embodiment 4, as described in embodiment 3, the difference is:

[0063] Add 140g of octaphenylcyclotetrasiloxane (D 4 Ph2 ) and 300g of 1# end-capping agent, 0.3g of potassium silanolate catalyst and N,N-dimethylacetamide 2.5g. The temperature of the closed reaction system was raised to 150°C. After about 10 minutes, the solid powder in the reaction bottle almost completely disappeared, and the viscosity increased, and then the temperature was lowered after being constant for 5 hours.

[0064] The reaction mixture cooled to 40° C. was neutralized by adding 0.5 g of propionic acid, filtered to remove low molecules, and a colorless, transparent, odorless methoxy-terminated polydiphenyldimethylsiloxane product was obtained. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com