Synthesis method of quaternized organosilicon modified acrylate emulsion

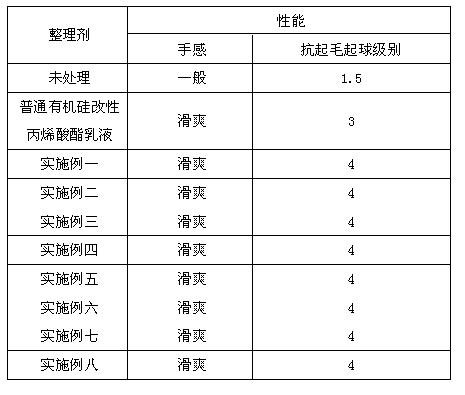

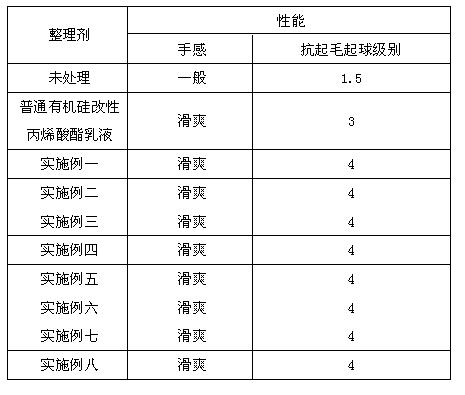

A quaternized silicone and quaternized modification technology, which is applied in the field of preparation of acrylate emulsions, can solve the problems of poor anti-pilling performance, loss of fabric style, stiff hand feeling, etc., achieve good hand feeling and improve durability Good anti-pilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Synthesis of amino silicone oil: 71.0g octamethylcyclotetrasiloxane, 12.0g methacryloxypropylmethyldiethoxysilane, 12.0g coupling agent KH-602, 0.6g capped Agent hexamethyldisiloxane, 0.7g catalyst potassium hydroxide and 3.9g deionized water were added to the reaction vessel, heated to 110°C, reacted for 5 hours, and the viscous liquid obtained after cooling was the synthesized amino silicone oil.

[0030] (2) Preparation of quaternized modified amino silicone oil: Add 0.8g bromoethane to the reaction vessel, dissolve in ethanol, heat to 70°C, add 100.0g amino silicone oil dropwise while stirring, and continue the reaction for 5 hours , heated up to 80° C., and reacted for another 2 hours to obtain quaternized modified amino silicone oil.

[0031] (3) Synthesis of quaternized silicone-modified acrylate emulsion: Ammonium persulfate and sodium bisulfite were formulated into aqueous solutions with a weight ratio of 3%, and then an appropriate amount of the two was m...

Embodiment 2

[0034] Use 7.0g methacryloxypropyl methyl diethoxysilane and 6.0g methacryloxypropyl silane coupling agent with double bond in the synthesis of amino silicone oil in Example 1 (1) Trimethoxysilane is replaced, and other raw material consumption and operation steps are identical with embodiment one.

Embodiment 3

[0036] Use 3.0g methacryloxypropyl methyl dimethoxysilane, 4.0g methacryloxypropyl Methyldiethoxysilane and 6.0 g of vinylmethyldiethoxysilane, other raw material consumption and operation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com