Method for preparing fluorine-containing silicon acrylate emulsion

A silicon acrylate and acrylate technology, which is applied in the field of acrylate modification, can solve the problems of fabrics with unpleasant smell of quaternary ammonium salt cationic surfactant residues, difficult biodegradation of fluoroalkanes, and unsatisfactory effects, etc. Industrial application prospect, excellent waterproof and oil-proof performance, and the effect of stable and excellent waterproof and oil-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

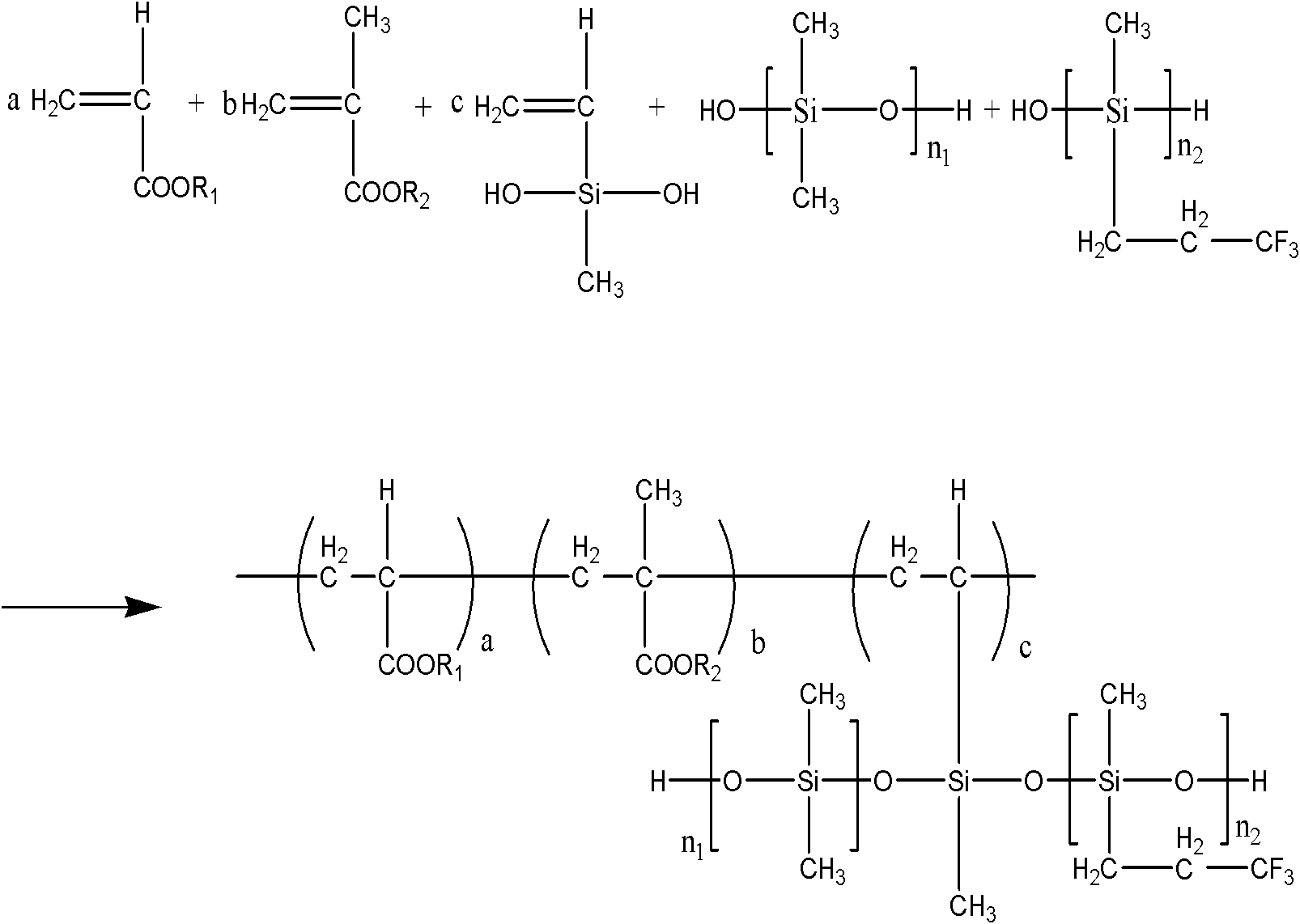

[0044] Embodiment one: the preparation process sees figure 2 : Mix 20 grams of octamethylcyclotetrasiloxane, 8 grams of 1,3,5-trimethyl-1,3,5-tris(3,3,3-trifluoropropyl)cyclotrisiloxane, 3 grams of tetramethyltetravinylcyclotetrasiloxane, 15 grams of methyl methacrylate, 35 grams of butyl acrylate, 1.5 grams of TX-10, 3 grams of fluorinated anionic emulsifier, 0.3 grams of APS, 0.6 grams of hydroxide Mix potassium and 120 grams of distilled water for 15 minutes under high shear, take out 1 / 3 of the emulsion and add it to a four-neck round bottom flask, turn on nitrogen protection, heat to 80°C while stirring, and drop the remaining 2 / 3 of the emulsion into the reaction flask within 3 hours , after all the drops were completed, the temperature was raised to 85°C, and the reaction was continued for 3 hours, then stirred and lowered to room temperature, and the discharge was filtered to obtain the target product.

Embodiment 2

[0045] Embodiment two: preparation process see figure 2 : Mix 35 grams of octamethylcyclotetrasiloxane, 8 grams of 1,3,5-trimethyl-1,3,5-tris(3,3,3-trifluoropropyl)cyclotrisiloxane, 5 grams of tetramethyltetravinyl cyclotetrasiloxane, 22.5 grams of methyl methacrylate, 27.5 grams of butyl acrylate, 4.7 grams of TX-10, 4.0 grams of fluorinated anionic emulsifier, 0.5 grams of APS, 0.7 grams of hydroxide Mix potassium and 100 grams of distilled water for 15 minutes under high shear, take out 1 / 3 of the emulsion and add it to a four-neck round bottom flask, turn on nitrogen protection, heat to 80°C while stirring, and drop the remaining 2 / 3 of the emulsion into the reaction flask within 3 hours , after all the drops were completed, the temperature was raised to 85°C, and the reaction was continued for 3 hours, then stirred and lowered to room temperature, and the discharge was filtered to obtain the target product.

Embodiment 3

[0046] Embodiment three: preparation process see figure 2 : Mix 35 grams of octamethylcyclotetrasiloxane, 10 grams of 1,3,5-trimethyl-1,3,5-tris(3,3,3-trifluoropropyl)cyclotrisiloxane, 5 grams of tetramethyltetravinyl cyclotetrasiloxane, 15 grams of methyl methacrylate, 35 grams of butyl acrylate, 4.5 grams of TX-10, 4.0 grams of fluorinated anionic emulsifier, 0.5 grams of APS, 0.7 grams of hydroxide Mix potassium and 100 grams of distilled water for 15 minutes under high shear, take out 1 / 3 of the emulsion and add it to a four-neck round bottom flask, turn on nitrogen protection, heat to 80°C while stirring, and drop the remaining 2 / 3 of the emulsion into the reaction flask within 3 hours , after all the drops were completed, the temperature was raised to 85°C, and the reaction was continued for 3 hours, then stirred and lowered to room temperature, and the discharge was filtered to obtain the target product.

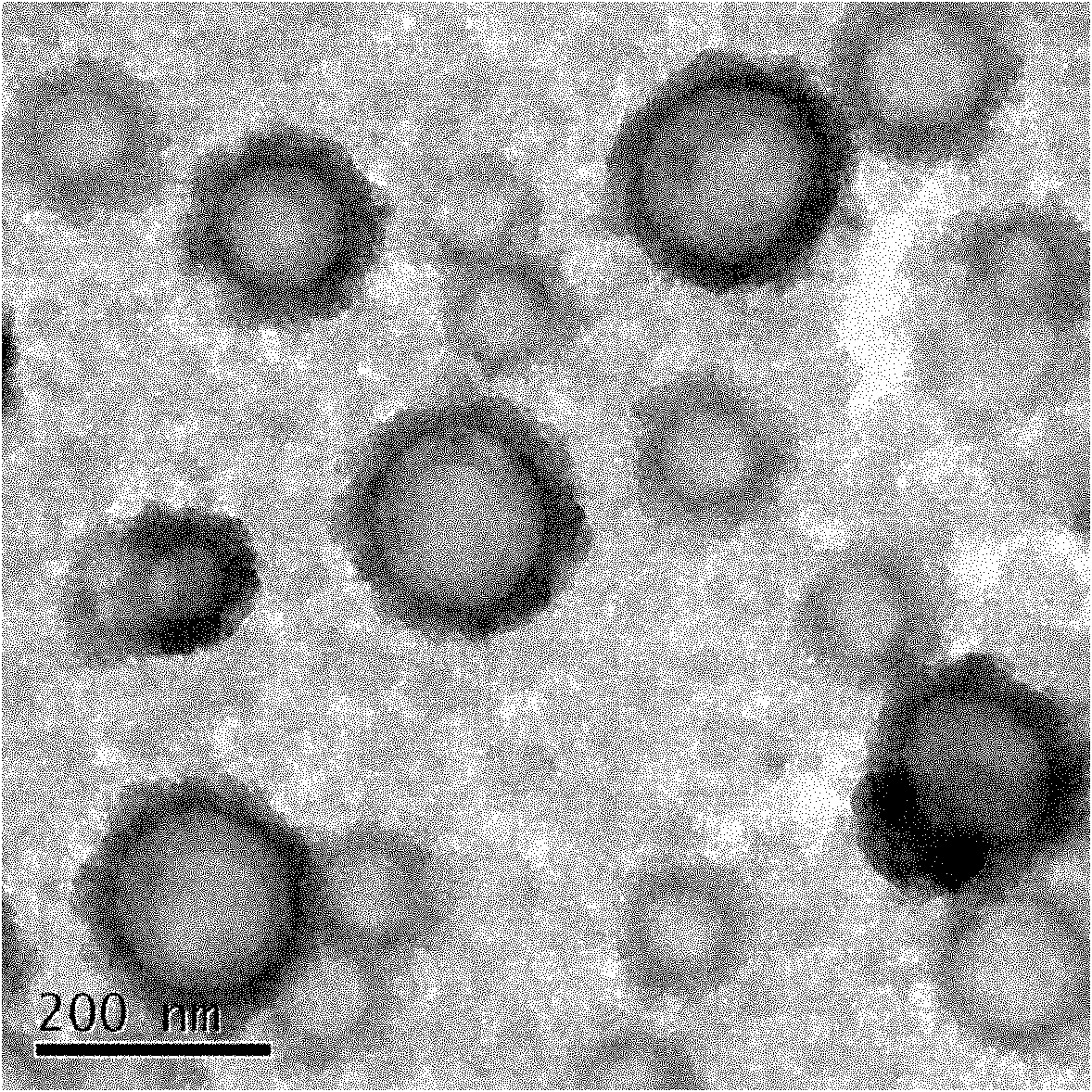

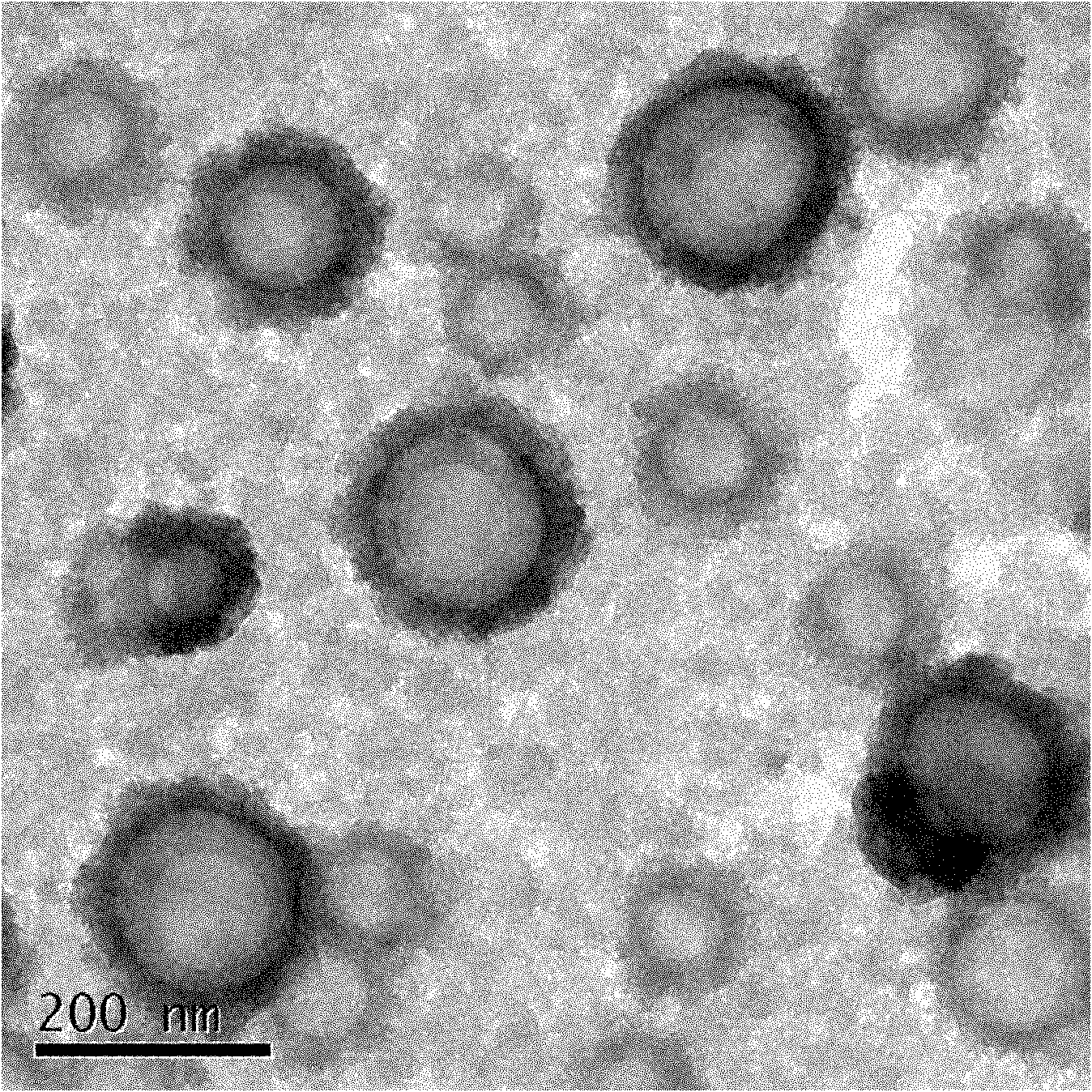

[0047] Carry out electron microscope analysis to embodiment th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com