Epoxy-group-containing fluorosilicone modified acrylate emulsion and preparation method thereof

A kind of acrylate, fluorosilicon modified technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A preparation method of a fluorosilicone acrylate emulsion containing epoxy groups, specifically comprising the following steps:

[0050] 1) Wash methyl methacrylate and butyl acrylate with 5% sodium hydroxide solution to remove the polymerization inhibitor; mix vinyl trimethoxysiloxane with washed methyl methacrylate and butyl acrylate, Add fluorine-containing emulsifiers FS-62 and TX-10, initiator potassium persulfate, and pH regulator potassium hydroxide, and pre-emulsify with a high-shear emulsifier for 15 minutes to obtain a pre-emulsion;

[0051] 2) Take 1 / 3 of the pre-emulsion, raise the temperature to 75-80°C, and stir under the protection of nitrogen at a stirring speed of 200r / min; the remaining 2 / 3 of the pre-emulsion is mixed with trifluoropropylmethylcyclotrisiloxane alkane and 3-glycidyl etheroxypropylmethyltrimethoxysilane for shearing and mixing, and the reactants after shearing were dropped into the reaction system within 3 hours; after all the drops we...

Embodiment 1

[0054] Mix 9.5 grams of methyl methacrylate, 19.0 grams of butyl acrylate, 2.04 grams of vinyltrimethoxysiloxane, 0.8 grams of TX-10, 1.7 grams of fluorine-containing anionic emulsifier, 0.1998 grams of APS and 150 grams of distilled water for high Cut for 15 minutes, take out 1 / 3 of the emulsion and add it to a 500mL four-neck round-bottomed flask, turn on nitrogen protection, heat to 80°C under stirring, add 4.5 grams of 1,3,5-trimethyl-1 to the remaining 2 / 3 of the emulsion , 3,5-tris(3,3,3-trifluoropropyl)cyclotrisiloxane and 2.2 g of 3-glycidyloxypropylmethyltrimethoxysilane were subjected to high shear for 10 minutes at Drop it into the reaction flask within 3 hours, raise the temperature to 85°C after all the drops are completed, continue the heat preservation reaction for 3 hours, then stir and cool down to room temperature, discharge and filter to obtain the target product.

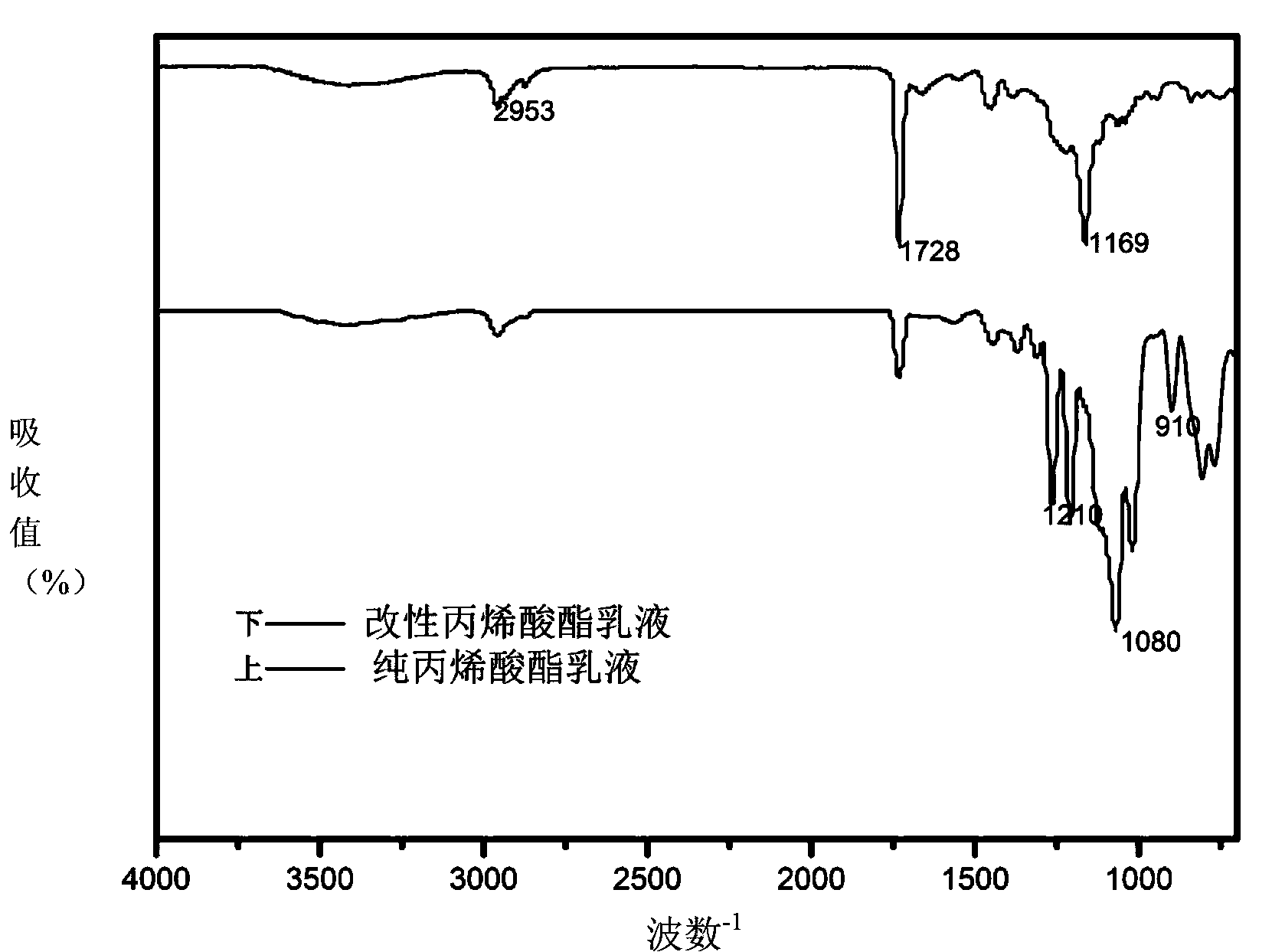

[0055] Carry out NMR and infrared characterization to embodiment 1 gained product, obtain fi...

Embodiment 2

[0059] Mix 9.5 grams of methyl methacrylate, 10.0 grams of butyl acrylate, 1.84 grams of vinyl triethoxysiloxane, 0.8 grams of TX-10, 1.7 grams of fluorine-containing anionic emulsifier, 0.1998 grams of APS and 150 grams of distilled water High shear for 15 minutes, take out 1 / 3 of the emulsion and add it to a 500mL four-neck round bottom flask, turn on nitrogen protection, heat to 80°C under stirring, add 3.1 grams of 1,3,5-trimethyl- 1,3,5-Tris(3,3,3-trifluoropropyl)cyclotrisiloxane and 1.4 g of 3-glycidyloxypropylmethyldiethoxysilane, high shear for 10 min , drop it into the reaction flask within 3 hours, raise the temperature to 85°C after all the drops are completed, continue the heat preservation reaction for 3 hours, then stir and cool down to room temperature, discharge and filter to obtain the target product.

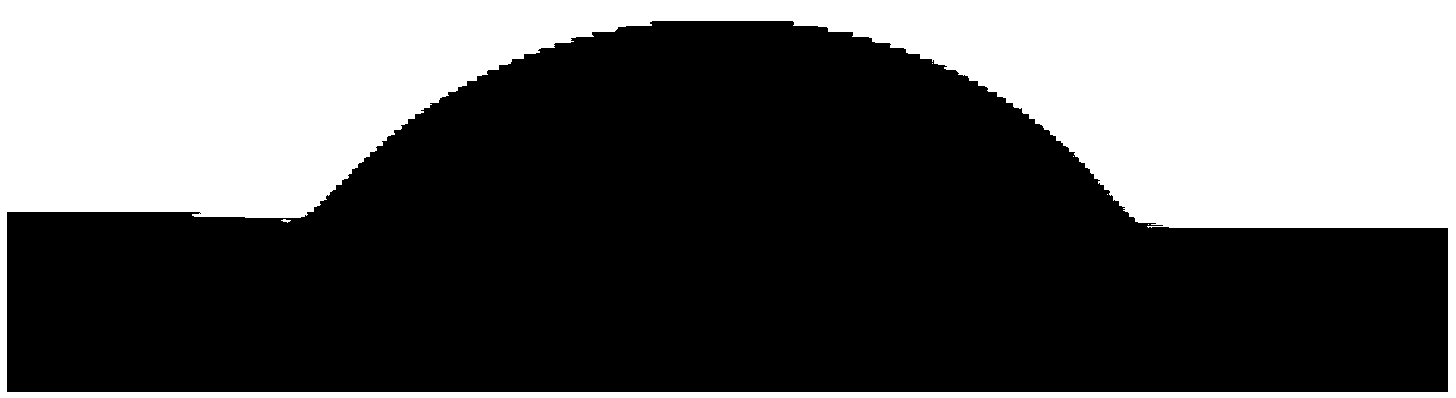

[0060] The contact angle obtained by spraying the emulsion obtained in Example 2 on the epoxy resin is 102.5°, and the hydrophobicity is very good, which basic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com