Polyether block piperazine silicone oil as well as preparation method and application thereof in cotton woven finishing

A technology of piperazine silicone oil and polyether block is applied in the field of preparation of new polyether block piperazine silicone oil, which can solve the problems of reduced wearing comfort, easy yellowing of fabrics, strong hydrophobicity, etc., and achieves improved hydrophilicity. , Improve the stability of emulsion, improve the effect of emulsifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

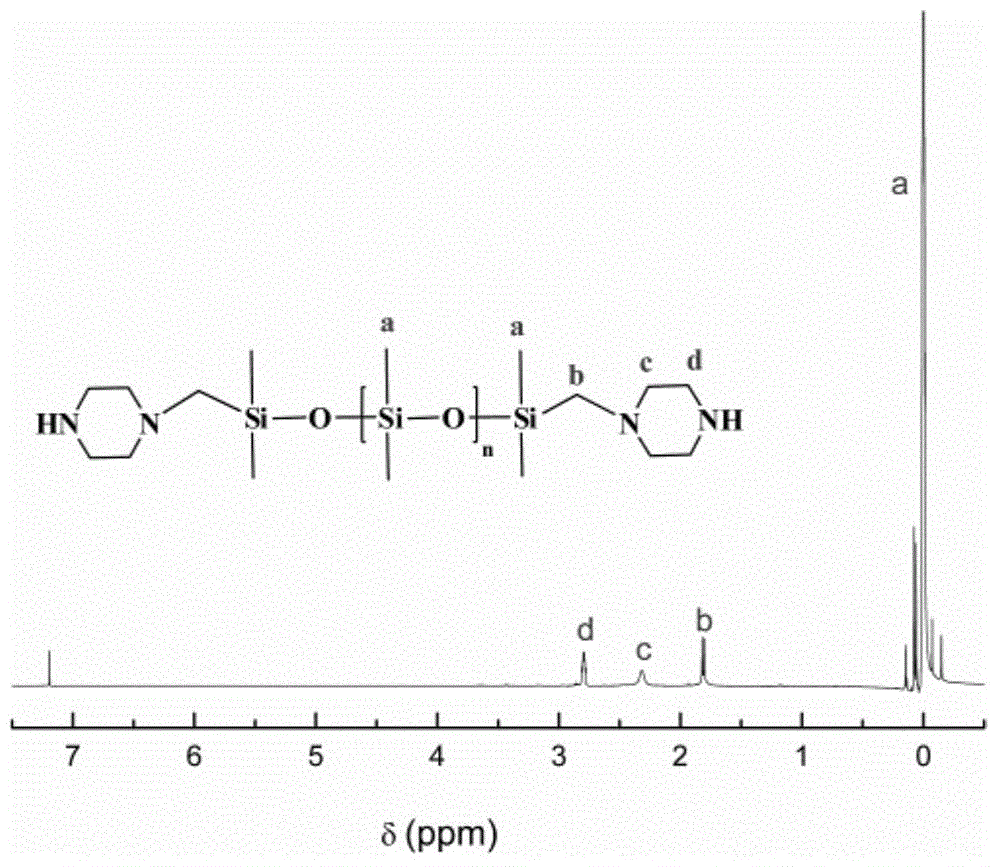

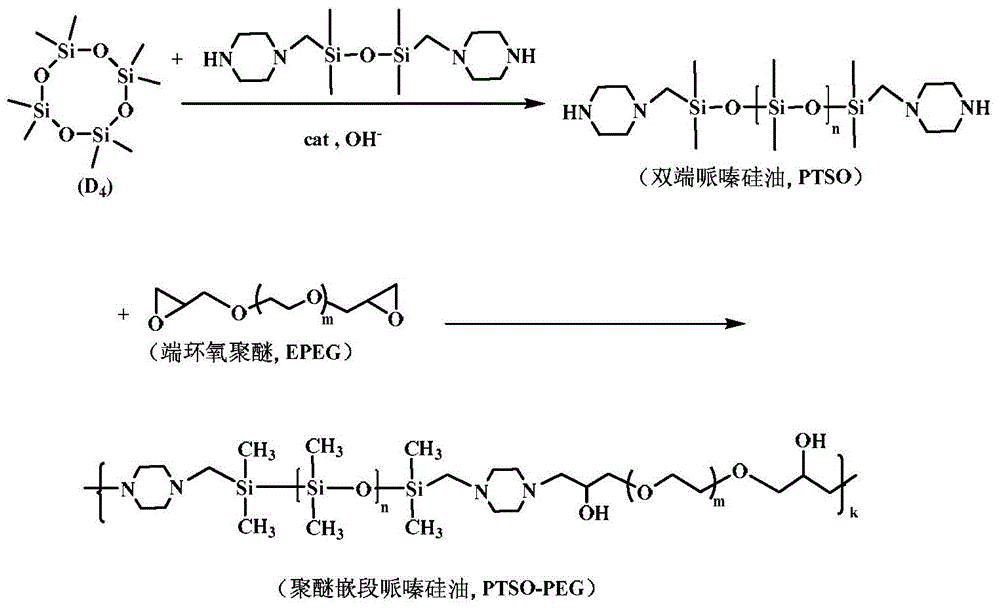

[0039] Octamethylcyclotetrasiloxane (D 4 ), piperazine double-capped heads, and catalyst tetramethylammonium hydroxide solid were added into a three-necked flask equipped with a magnetic stirrer, a thermometer, and a condenser at a mass ratio of 100:6.6:0.02, and stirred under a nitrogen atmosphere to raise the temperature to 90°C React for 10 hours, then raise the temperature to 150°C and keep it for 1 hour to decompose the tetramethylammonium hydroxide catalyst, and finally distill under reduced pressure at 150°C to remove the low boiling point, and the obtained colorless, transparent and viscous product is bismuth with a molar mass of about 5000g / mol Piperazine-terminated polysiloxane, labeled PTSO1 (see image 3 ).

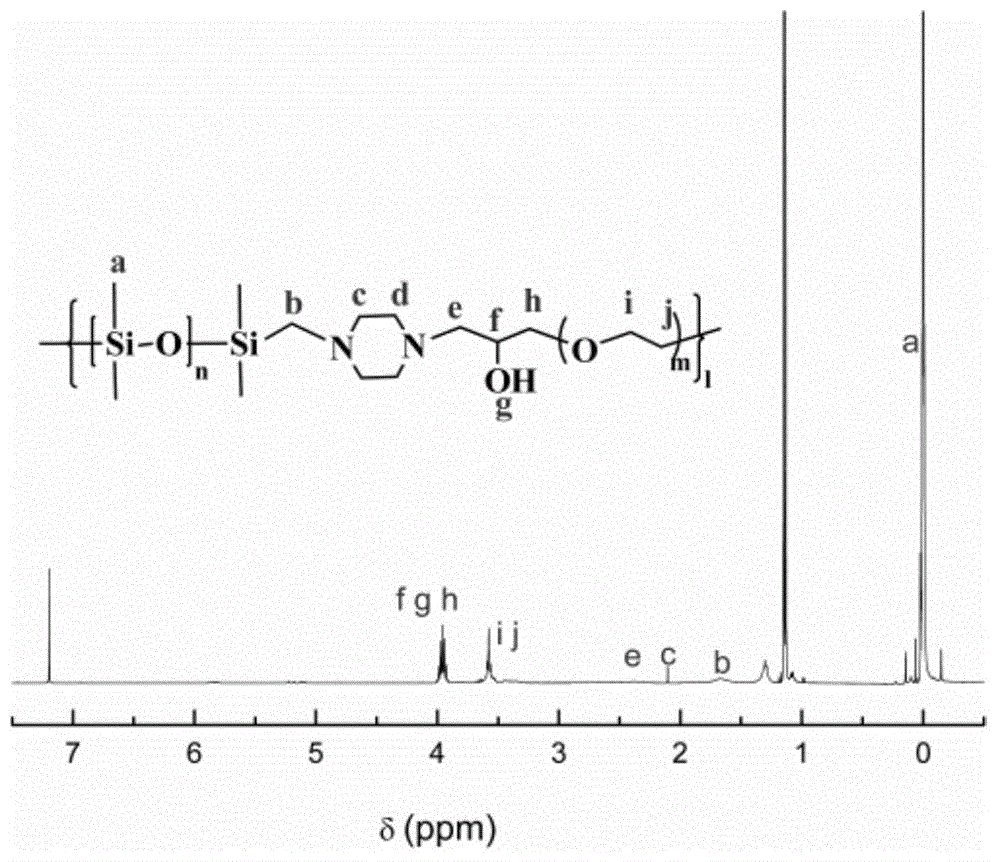

[0040] Add double-ended piperazine polysiloxane PTSO1 and double-ended epoxy polyether (molar mass 600g / mol, marked as EPEG, industrial product, purchased from Wuxi Huilong Electronic Materials Co., Ltd.) into the flask in an equimolar mass ratio , add 40wt....

Embodiment 2

[0042] Octamethylcyclotetrasiloxane (D 4 ), piperazine double-capped heads and catalyst KOH were added into a three-necked flask equipped with a magnetic stirrer, a thermometer and a condenser at a mass ratio of 100:3.3:0.02, stirred and heated to 90°C for 10 hours under a nitrogen atmosphere, and finally heated at 150°C Distill under reduced pressure to remove the low boiling point, and the obtained colorless and transparent viscous product is a double-ended piperazine polysiloxane with a molar mass of about 10,000 g / mol, marked as PTSO2.

[0043] Add double-ended piperazine polysiloxane PTSO2 and double-ended epoxy polyether (molar mass 600g / mol, marked as EPEG) into the flask in an equimolar mass ratio, and add 40wt.% isopropanol in the total amount of reactants to make Solvent, heat up to 80°C, and react for 6-7 hours to obtain polyether block piperazine silicone oil (PTSO2-PEG). The solvent isopropanol can be used as a dilution stabilizer for silicone oil and as a small m...

Embodiment 3

[0045] Octamethylcyclotetrasiloxane (D 4), piperazine double-capped heads, and catalyst NaOH were added to a three-necked flask equipped with a magnetic stirrer, a thermometer, and a condenser at a mass ratio of 100:1.65:0.02, stirred and heated to 90°C for 10 hours under a nitrogen atmosphere, and finally heated at 150°C Distill under reduced pressure to remove the low boiling point, and the obtained colorless and transparent viscous product is a double-ended piperazine polysiloxane with a molar mass of about 20,000 g / mol, marked as PTSO3.

[0046] Add double-ended piperazine polysiloxane PTSO3 and double-ended epoxy polyether (molar mass 600g / mol, marked as EPEG) into the flask in an equimolar mass ratio, and add 40wt.% isopropanol in the total amount of reactants to make Solvent, heat up to 80°C, and react for 6-7 hours to obtain polyether block piperazine silicone oil (PTSO3-PEG). The solvent isopropanol can be used as a dilution stabilizer for silicone oil and as a small ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com