Method and device for producing disilane through reaction of alloyed composition and ammonium chloride in liquid ammonia

A technology of alloying and compounding, applied in the direction of silicon hydride, etc., can solve the problems of difficult production of monosilane, limited practicality, high alloying temperature, etc., and achieve the effects of high yield, improved production efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

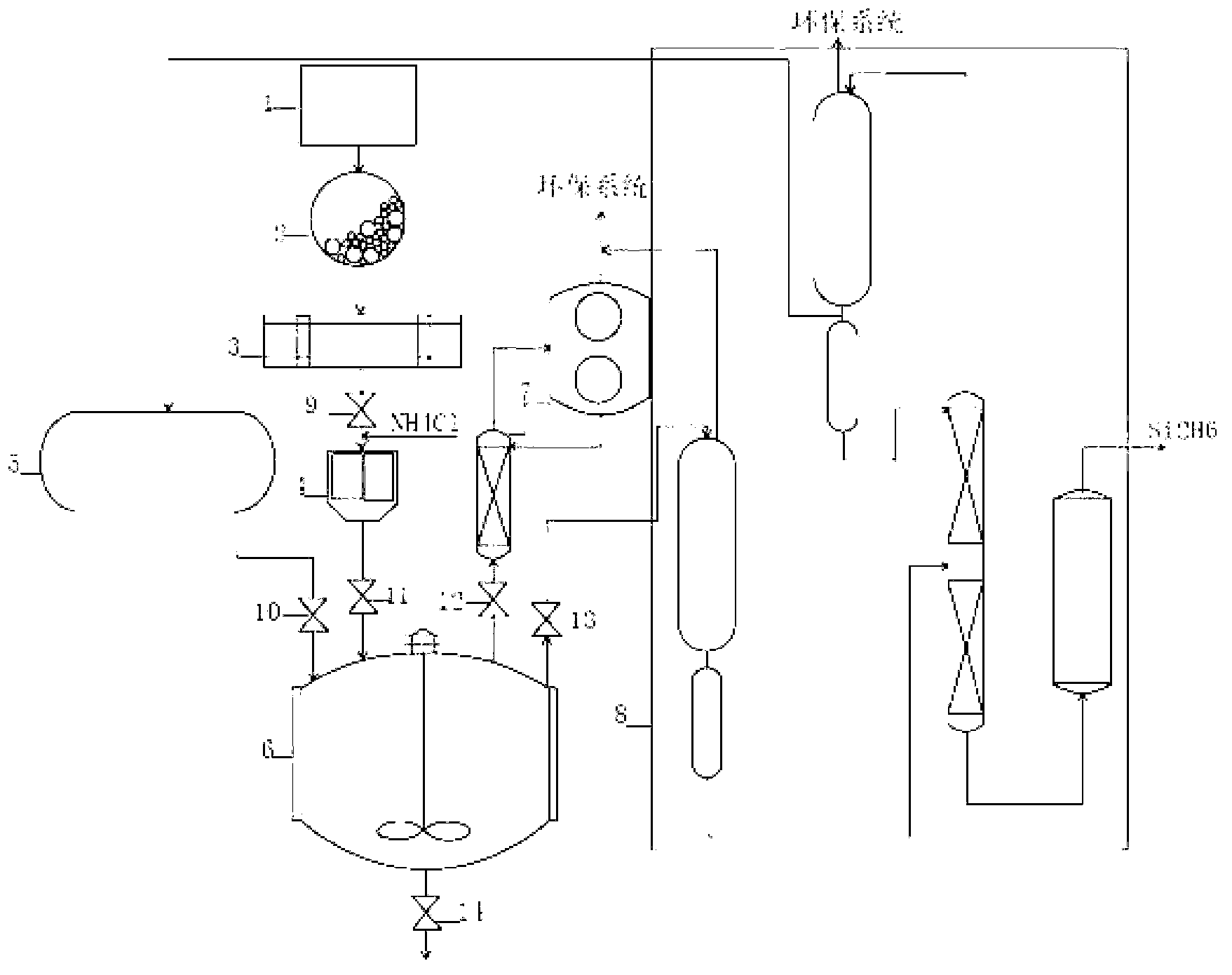

Method used

Image

Examples

Embodiment 1

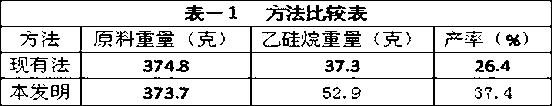

[0030] A method for producing disilane by mechanically compounding hydrogenated metal-silicon after alloying and chemically reacting with ammonium chloride in a liquid ammonia medium, characterized in that the composition of the hydrogen-metal-silicon compound is Si 33.2%, Mg 66.5%, H 0.3%, the above percentages are molar percentages, and the reaction is carried out according to the following principles to improve reaction efficiency and disilane productive rate:

[0031] SiO 2 + 2MgH 2 =SiMg 2 + 2H 2 O

[0032] SiMg 2 H 0.01 + NH 4 Cl → MgCl 2 + H 2 + NH 3 + SiH 4 + Si 2 H 6

[0033]The alloying temperature is 500°C, monosilane is completely absorbed and transformed by the reflux silane absorption converter, the gas-liquid separation temperature is controlled at -40°C, and monosilane reacts with 2N KOH aqueous solution to produce hydrogen and potassium silicate, no by-products are produced, After disilane is sepa...

Embodiment 2

[0035] A method for producing disilane by mechanically compounding hydrogenated metal-silicon after alloying and chemically reacting with ammonium chloride in a liquid ammonia medium, characterized in that the composition of the hydrogen-metal-silicon compound is Si 32.1%, Mg 64.4%, V 3.2%, H 0.3%, the above percentages are mole percentages, and the reaction is carried out according to the following principles to improve efficiency and disilane yield:

[0036] SiO 2 + 2MgH 2 =SiMg 2 + 2H 2 O

[0037] SiMgV 0.1 H 0.01 + NH 4 Cl → MgCl 2 + VCl 2 + H 2 + SiH 4 + Si 2 H 6

[0038] The alloying temperature is 550°C, the reaction is safe and stable, monosilane is completely absorbed and transformed by the reflux silane absorption converter, no by-products are produced, and disilane is separated and purified to obtain high-purity products.

Embodiment 3

[0040] A method for producing disilane by mechanically compounding hydrogenated metal-silicon after alloying and chemically reacting with ammonium chloride in a liquid ammonia medium, characterized in that the composition of the hydrogen-metal-silicon compound is Si 31.1%, Mg 62.1%, Fe 3.1%, H 2.5%, Li 0.6%, Al 0.6%, the above percentages are mole percentages, and the reaction is carried out according to the following principles to improve reaction efficiency and disilane yield:

[0041] Mg + SiO 2 + LiAlH 4 →SiMg 2 + H 2 O

[0042] Li 0.02 SiMg 2 Fe 0.1 Al 0.02 H 0.08 + NH 4 Cl → MgCl 2 + FeCl 2 +H 2 + SiH 4 + Si 2 H 6

[0043] The alloying temperature is low, the reaction is safe and stable, monosilane is completely absorbed and transformed by the reflux silane absorption converter, monosilane is cracked at 600°C high temperature, no by-products are produced, and disilane is separated and purified t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com