Modified acrylic resin for preparing artificial colored sand and preparation method of artificial colored sand

A technology of acrylic resin and artificial colored sand, applied in coatings, multi-color effect coatings, etc., can solve the problems of resin adhesion, hardness, poor acid and alkali resistance and weather resistance, achieve diversification of colors, improve adhesion, The effect of good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

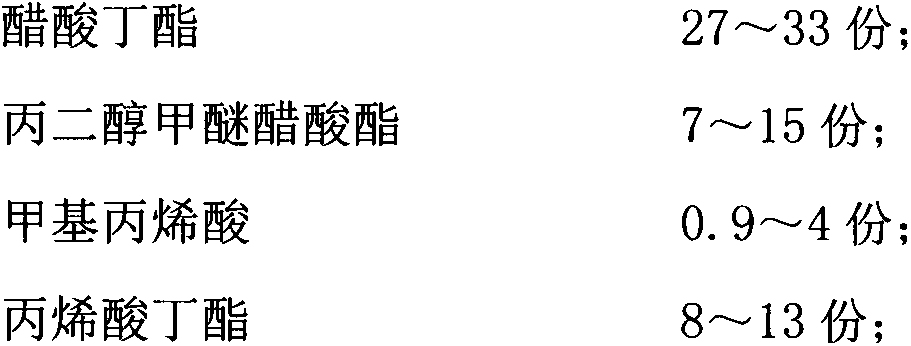

[0025] The formula of modified acrylic resin for the preparation of artificial colored sand is shown in the table below:

[0026]

[0027] Preparation process: first put group A into a 500ml four-neck flask equipped with a stirrer, reflux condenser, thermometer and dropping funnel, heat to reflux while stirring, then add component B dropwise evenly, and finish dropping in 4 hours After dripping, keep warm and reflux for 4 hours, then take a sample and test it to pass the test, then cool down, filter, discharge, and pack.

[0028] The modified acrylic resin prepared in this embodiment has the technical indicators as shown in the table below:

[0029] project

Embodiment 2

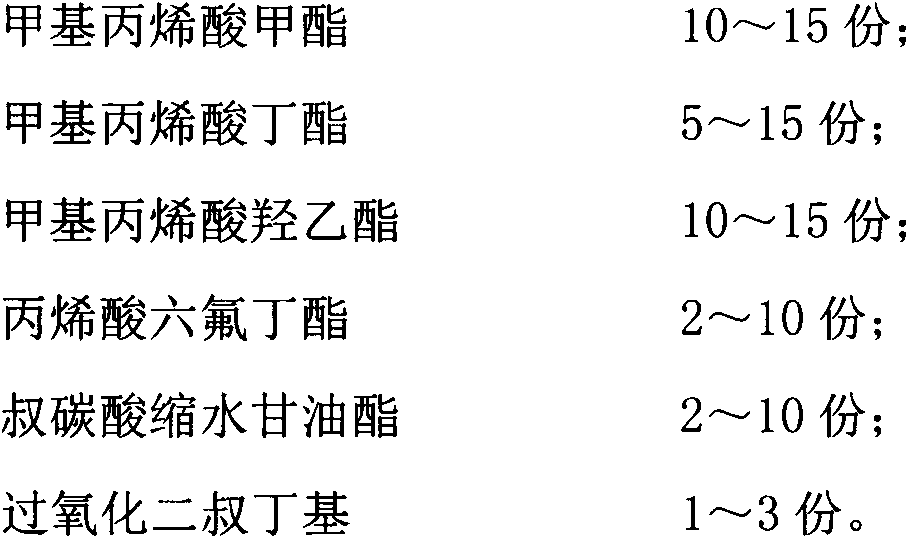

[0031] The formula of modified acrylic resin for the preparation of artificial colored sand is shown in the table below:

[0032]

[0033] The preparation process is the same as in Example 1.

Embodiment 3

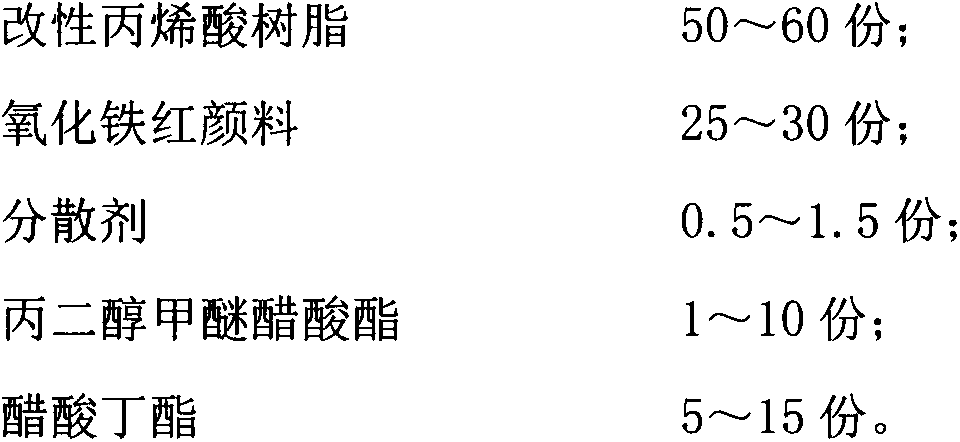

[0035] The formula of modified acrylic resin for the preparation of artificial colored sand is shown in the table below:

[0036]

[0037]

[0038] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com