Bacterial inhibition high-hardness shoe material and preparation method thereof

A high-hardness, shoe material technology, used in footwear, applications, clothing, etc., can solve problems such as poor flexibility, poor folding resistance, and no wear resistance, and achieve the effect of improving bacteria resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

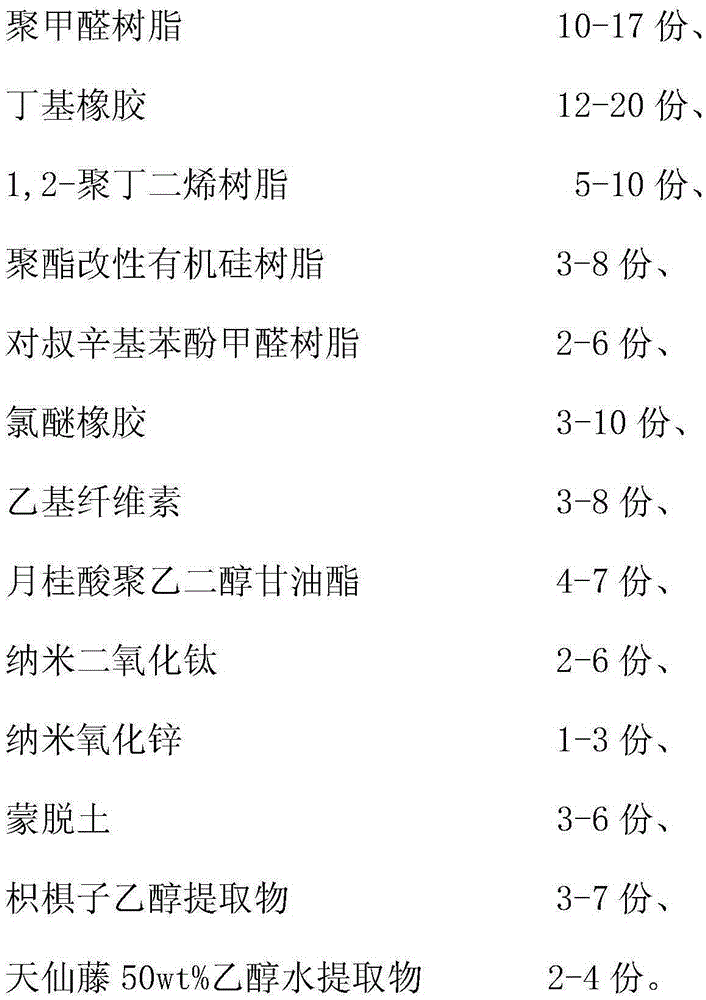

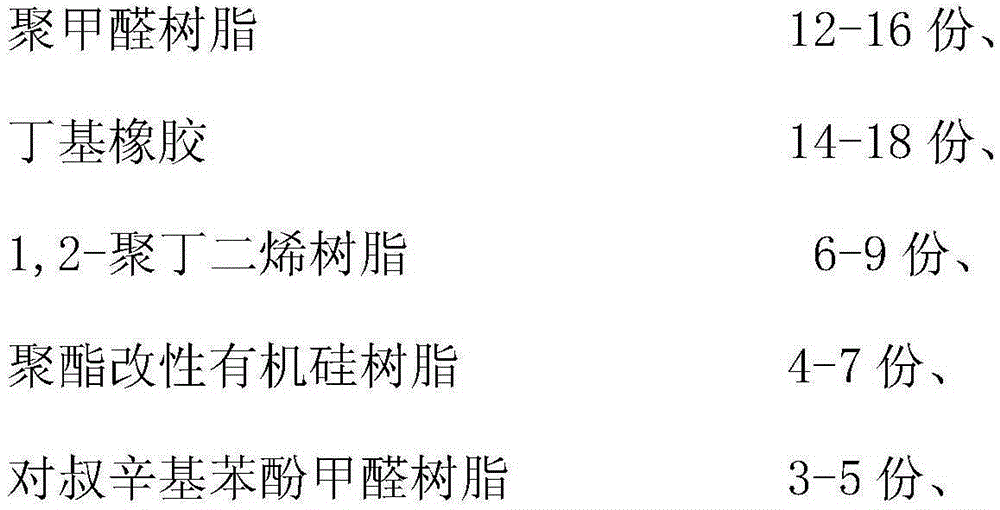

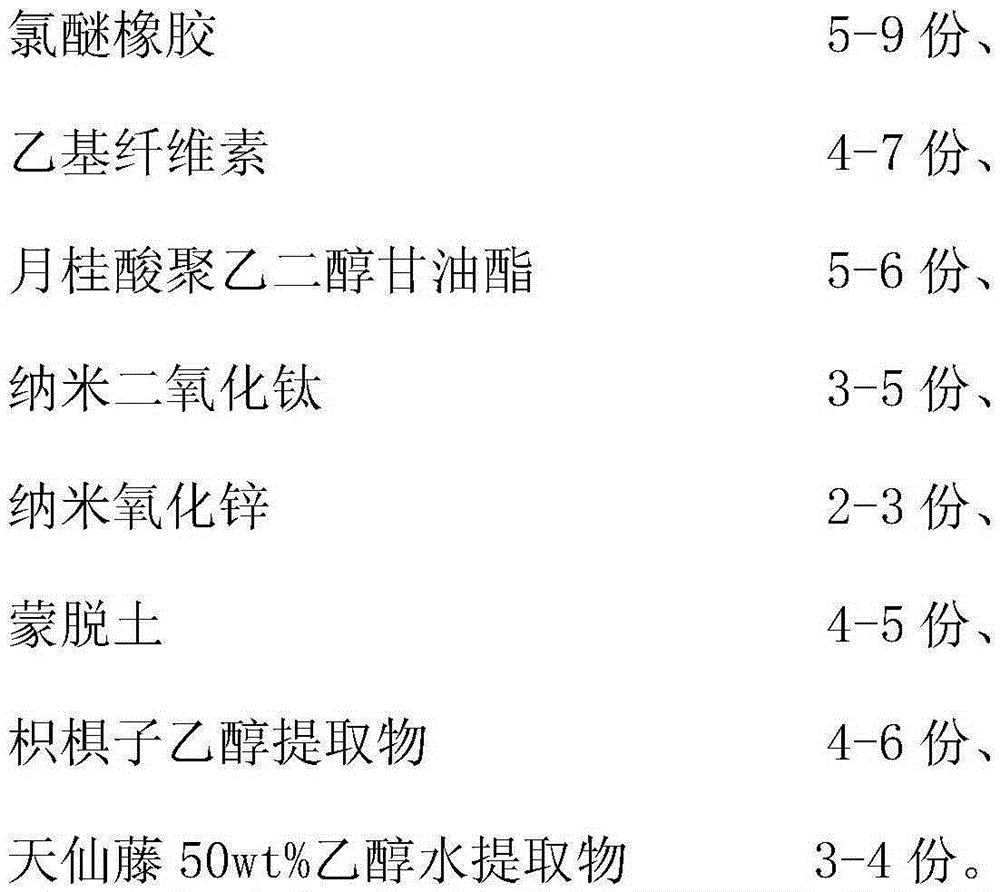

Method used

Image

Examples

Embodiment 1

[0019] (1) Vacuum-dry Hovenia dulcis and Angelica vine, respectively, after vacuum-drying, stir and extract with ethanol and 50wt% ethanol aqueous solution respectively, the extraction temperature is 60°C, the extraction time is 2h, and the weight ratio of solid to liquid is 1:8, Filtration after leaching, vacuum concentration of the filtrate respectively, after concentration, the ethanol extract of Hovenia dulcis and the 50wt% ethanol water extract of Caulis radix are obtained;

[0020] (2) Set the temperature in the reactor to 85°C, add 17 parts of polyoxymethylene resin, 12 parts of butyl rubber, 5 parts of 1,2-polybutadiene resin, and 3 parts of polyester modified silicone resin by weight , 6 parts of p-tert-octylphenol formaldehyde resin, 10 parts of epichlorohydrin rubber, 3 parts of ethyl cellulose, 7 parts of macrogol glyceride laurate, mechanically stir the material in the reaction kettle, the stirring speed is 90rpm, Stir well;

[0021] (3) The temperature in the re...

Embodiment 2

[0023] (1) Vacuum-dry Hovenia dulcis and Angelica vine, respectively, and carry out stirring extraction with ethanol and 50wt% ethanol aqueous solution after vacuum drying, the extraction temperature is 50°C, the extraction time is 5h, and the weight ratio of solid to liquid is 1:4. Filtration after leaching, vacuum concentration of the filtrate respectively, after concentration, the ethanol extract of Hovenia dulcis and the 50wt% ethanol water extract of Caulis radix are obtained;

[0024] (2) Set the temperature in the reactor to 65°C, add 10 parts of polyoxymethylene resin, 20 parts of butyl rubber, 10 parts of 1,2-polybutadiene resin, and 8 parts of polyester modified silicone resin by weight , 2 parts of p-tert-octylphenol formaldehyde resin, 3 parts of epichlorohydrin rubber, 8 parts of ethyl cellulose, 4 parts of macrogol glyceride laurate, mechanically stir the material in the reactor, the stirring speed is 50rpm, Stir well;

[0025] (3) The temperature in the reactio...

Embodiment 3

[0027] (1) Vacuum-dry Hovenia dulcis and Angelica vine, respectively, after vacuum-drying, stir and extract with ethanol and 50wt% ethanol aqueous solution respectively, the extraction temperature is 60°C, the extraction time is 2h, and the weight ratio of solid to liquid is 1:8, Filtration after leaching, vacuum concentration of the filtrate respectively, after concentration, the ethanol extract of Hovenia dulcis and the 50wt% ethanol water extract of Caulis radix are obtained;

[0028] (2) Set the temperature in the reactor to 85°C, add 12 parts of polyoxymethylene resin, 18 parts of butyl rubber, 6 parts of 1,2-polybutadiene resin, and 7 parts of polyester modified silicone resin by weight , 3 parts of p-tert-octylphenol formaldehyde resin, 5 parts of epichlorohydrin rubber, 4 parts of ethyl cellulose, 6 parts of macrogol glyceride laurate, mechanically stir the material in the reaction kettle, the stirring speed is 90rpm, Stir well;

[0029] (3) The temperature in the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com