High-oil-resistant ethylene-propylene-diene monomer rubber sealing gasket and preparing method thereof

A technology of EPDM rubber and gaskets, which is applied in the field of rubber gaskets, can solve problems such as poor oil resistance, short service life, and failure to meet market demand, and achieve improved mechanical properties, wear resistance, and airtight performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

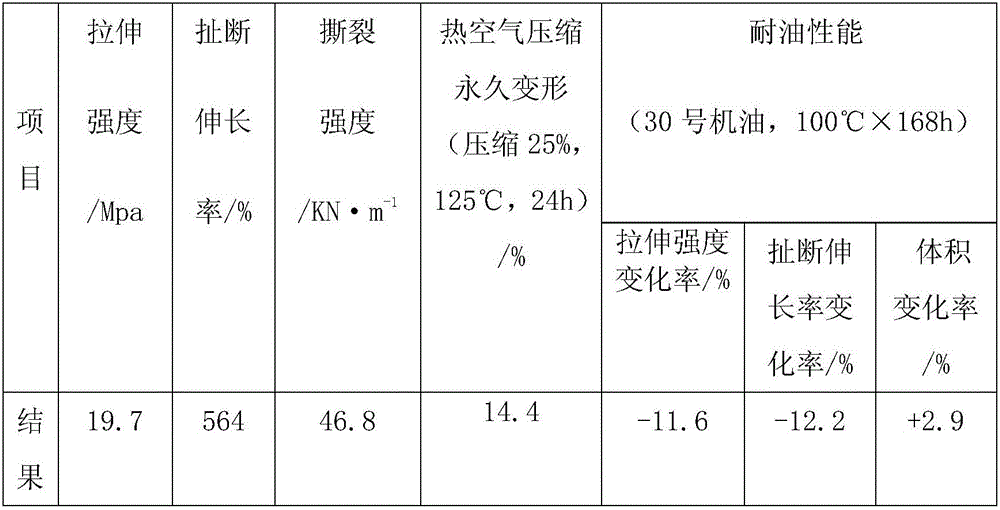

Examples

Embodiment Construction

[0015] A high oil-resistant EPDM rubber gasket, made of the following raw materials by weight (kg): EPDM rubber 57, polysulfide rubber 43, chlorosulfonated polyethylene rubber 26, crosslinking agent SQS3506, alginate 9. Basic magnesium sulfate whisker 20, naphthenic oil 9, tetraethylthiuram disulfide 2.5, 2-mercaptobenzimidazole 1.5, bromomethyl p-tert-octylphenol formaldehyde resin 6, N,N'- Bisfurylidene acetone 5, zinc carbonate 3, dibutyl diglyceride adipate 12, steel slag fine powder 18, 2,5-di-tert-butyl hydroquinone 2.5, modifier 19;

[0016] The preparation method of described modifying agent is as follows: (1) get the raw material of following weight (kg): blast furnace water-quenched slag 16, titanium carbide 14, aluminum-magnesium spinel 12, silicon boride 11, cocoyl methyl boron Sodium Sulfonate 2.5, Lauryl Phosphate Betaine 2, Glucosaminoglycan 1.5, Tallow Amine Polyoxyethylene Ether 5, Jojoba Acid Polyoxypropylene Ester 4, Sorbitol Polyoxyethylene Ether Tetraoleat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com