A kind of oil-resistant cable material for railway locomotive vehicle cable and preparation method thereof

A technology for railway locomotives and cable materials, which is used in organic insulators, rubber insulators, etc. to achieve the effects of excellent oil resistance, extended service life and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

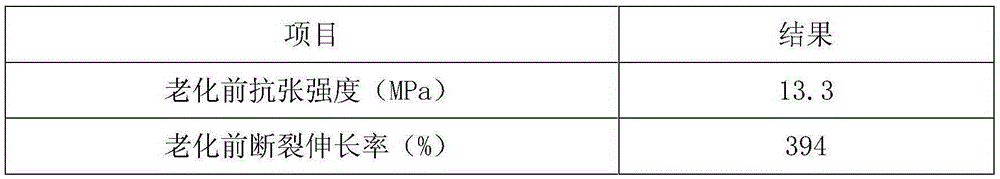

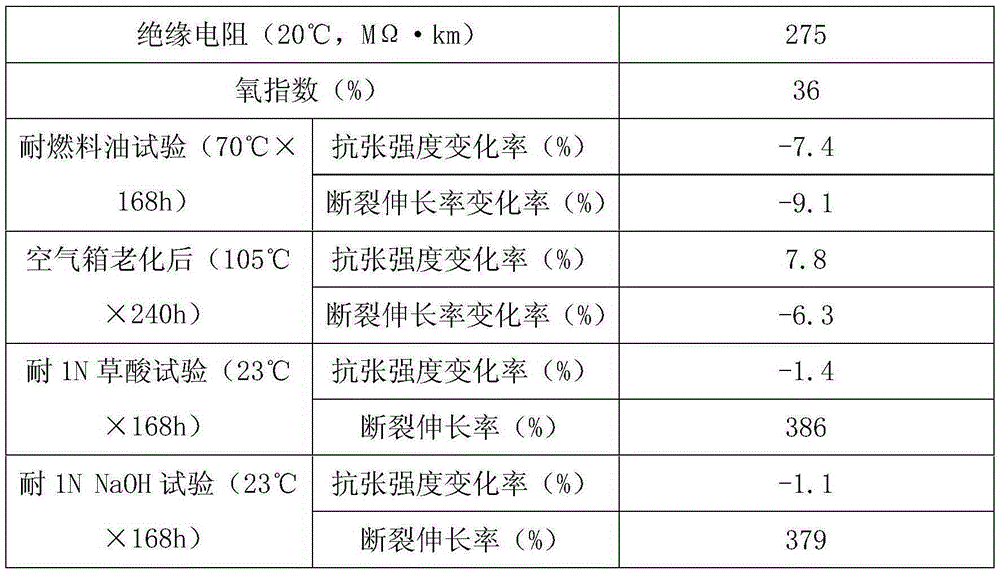

Examples

Embodiment Construction

[0013] An oil-resistant cable material for railway rolling stock cables, made of the following raw materials in parts by weight: high styrene rubber 70, nitrile rubber 50, neoprene rubber 30, bromomethyl-p-tert-octylphenol formaldehyde resin 18, cis-butadiene Dibutyl enediolate 12, polychlorinated biphenyl 14, tris(chloropropyl)phenyl silicate 12, nano barium titanate 15, heavy calcium powder 16, fly ash 7, quick extruded carbon black N55028, Di-tert-butyl peroxide 3.5, dibenzoyl p-quinone dioxime 5, isocyanate propyltriethoxysilane 2.5, basic lead carbonate 4, calcium oxide 2.5, transformer oil 8, liquid paraffin 5, Palmitic acid monoglyceride 4, tetraethylthiuram disulfide 1.5, N-tert-butyl-2-benzothiazole sulfenamide 2, 6-ethoxy-2,2,4-trimethyl-1 , 2-dihydroquinoline 2, modified stone powder 15;

[0014] The preparation method of the modified stone powder is as follows: (1) Weigh coke gemstones, volcanic stones, and attapulgite at a weight ratio of 6:4:3, mix them uniforml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com