High-strength multifunctional polyethylene communication tubular product

A communication pipe and polyethylene technology, applied in the field of communication, can solve the problems affecting the service life, stiffness, elastic modulus performance index imbalance, easy to produce brittleness, etc., to achieve good corrosion resistance, elastic modulus performance index, comprehensive performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

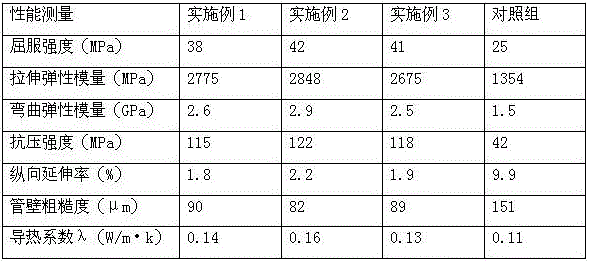

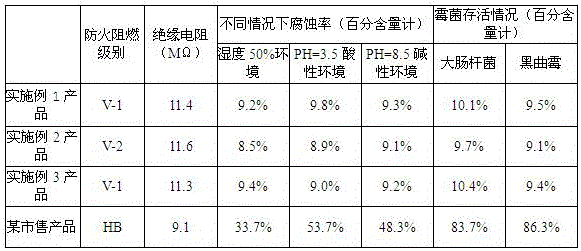

Embodiment 1

[0017] The high-strength multifunctional polyethylene communication pipe in this embodiment is composed of the following components in parts by mass: 22 parts of polyethylene, 20 parts of acrylic resin, 20 parts of polyaldehyde resin, 18 parts of polyketone resin, p-tert-octyl 20 parts of phenol formaldehyde resin, 20 parts of clove oil, 18 parts of anthracene oil, 20 parts of pepper oil, 20 parts of polyglycerol, 18 parts of cottonseed oil, 18 parts of hydrogen peroxide, 18 parts of oxymatrine, 20 parts of propargyl chloride, 18 parts of octadecyl dimethyl ammonium chloride, 16 parts of aluminum phosphate powder, 20 parts of boronite powder, 18 parts of methyl tert-butyl ether, 16 parts of n-butyl stearate, methallyl sulfide 18 parts of ether, 16 parts of zinc fluoride, 16 parts of dolomite powder, 16 parts of boron nitride powder, 14 parts of hydrated zinc borate, 10 parts of aluminum stearate, 8 parts of zinc hydroxystannate, 8 parts of hexabromocyclododecane 8 parts, 8 par...

Embodiment 2

[0024] The high-strength multifunctional polyethylene communication pipe in this embodiment is composed of the following components in parts by mass: 24 parts of polyethylene, 22 parts of acrylic resin, 22 parts of polyaldehyde resin, 20 parts of polyketone resin, p-tert-octyl 22 parts of phenol formaldehyde resin, 22 parts of clove oil, 20 parts of anthracene oil, 22 parts of pepper oil, 22 parts of polyglycerin, 20 parts of cottonseed oil, 20 parts of hydrogen peroxide, 20 parts of oxymatrine, 22 parts of propargyl chloride, 20 parts of octadecyl dimethyl ammonium chloride, 18 parts of aluminum phosphate powder, 22 parts of boronite powder, 20 parts of methyl tert-butyl ether, 18 parts of n-butyl stearate, methallyl sulfide 20 parts of ether, 18 parts of zinc fluoride, 18 parts of dolomite powder, 18 parts of boron nitride powder, 16 parts of hydrated zinc borate, 12 parts of aluminum stearate, 10 parts of zinc hydroxystannate, 10 parts of hexabromocyclododecane 10 parts, 10...

Embodiment 3

[0031] The high-strength multifunctional polyethylene communication pipe in this embodiment is composed of the following components in parts by mass: 26 parts of polyethylene, 24 parts of acrylic resin, 24 parts of polyaldehyde resin, 22 parts of polyketone resin, p-tert-octyl 24 parts of phenol formaldehyde resin, 24 parts of clove oil, 22 parts of anthracene oil, 24 parts of pepper oil, 24 parts of polyglycerin, 22 parts of cottonseed oil, 22 parts of hydrogen peroxide, 22 parts of oxymatrine, 24 parts of propargyl chloride, 22 parts of octadecyl dimethyl ammonium chloride, 20 parts of aluminum phosphate powder, 24 parts of boronite powder, 22 parts of methyl tert-butyl ether, 20 parts of n-butyl stearate, methallyl sulfide 22 parts of ether, 20 parts of zinc fluoride, 20 parts of dolomite powder, 20 parts of boron nitride powder, 18 parts of hydrated zinc borate, 14 parts of aluminum stearate, 12 parts of zinc hydroxystannate, 12 parts of hexabromocyclododecane 12 parts, 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com